How to Choose the Size of Lanthanum Tungsten Electrode According to the Application?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:17

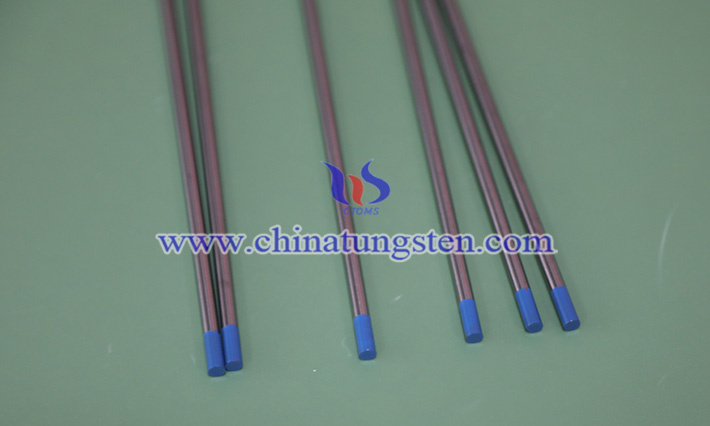

Tungsten inert gas welding (TIG) and plasma welding, the choice of electrode material plays a decisive role in the welding quality. With the widespread application of environmentally friendly materials, lanthanum tungsten electrode has gradually become an important choice in the welding industry.

In addition to the material properties themselves, the selection of size is also one of the key factors that determine the success or failure of welding. The diameter and length of the electrode are not only related to the arc starting performance and arc stability, but also affect the heat input, penetration depth, weld appearance and electrode life. So, how to choose the appropriate size specifications according to the actual application scenario?

1. Relationship between electrode diameter and current matching

Welding rods of different diameters are suitable for different current ranges. An electrode with a diameter that's too small can easily melt and burn under high currents. Conversely, an electrode with a diameter that's too large can make it difficult to start a stable arc under low currents. Therefore, when selecting electrode diameter, the welding current range should be considered first.

For example, in stainless steel thin plate welding, 1.0mm or 1.6mm diameter electrodes are usually selected; while in thick-walled pressure vessels, aluminum alloy structures or titanium alloy welding, 2.4mm or even 3.2mm electrodes are selected to match larger currents.

2. Welding process and material matching

Different welding materials have different requirements for heat input, which will also affect the choice of electrode size. For example:

1.6mm or 2.4mm size is recommended, which provides stable arc starting and good arc focusing under medium current conditions.

Titanium alloy, aluminum: welding these materials with high thermal conductivity usually requires a larger current, so it is recommended to choose an electrode size of 2.4mm or more, especially in AC welding.

Ultra-thin workpieces and micro-welding applications: 1.0 mm or even smaller electrodes can be used, and a micro-current power supply can be used to achieve fine control.

3. Electrode length and equipment adaptation

Standard products are usually provided in lengths of 150mm or 175mm, but in some automated equipment, welding robots or special fixtures, it may be necessary to cut to a specified length. Generally speaking:

Manual welding: It is recommended to use standard length, which is easier to clamp and replace.

Automatic welding equipment: The length should be adjusted according to the specifications of the equipment electrode chuck to ensure that the exposed part of the electrode is reasonable, neither too short to make arcing difficult, nor too long to affect arc stability.

4. Electrode grinding angle and size linkage

Thicker lanthanum tungsten electrodes require a larger sharpening angle (usually 30°–60°) to improve arc focusing and prevent overheating and melting of the electrode end. Therefore, when choosing larger size products, the sharpening quality has a more obvious impact on its performance.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com