What Are the Common Types of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:03

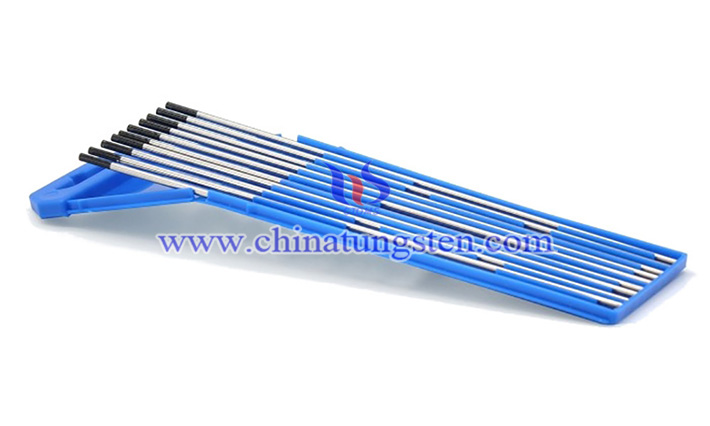

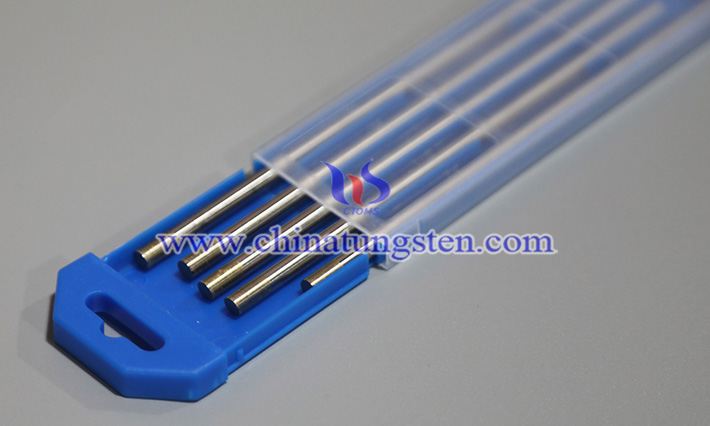

In modern welding, tungsten-based welding materials doped with the rare earth element lanthanum have become an indispensable electrode material in industrial manufacturing due to their excellent arc starting performance and environmentally friendly properties.

Compared to traditional thorium-containing products, these environmentally friendly alloys not only improve welding efficiency but also meet safety standards. Several standard types have been developed to suit different welding conditions and materials, allowing engineers to make targeted choices. So, what are the most common lanthanum tungsten electrode types on the market, and what are the differences between them?

Three most widely used specifications are WL10, WL15, and WL20. The numbers here represent the lanthanum oxide (La₂O₃) doping ratios: 1.0%, 1.5%, and 2.0%, respectively. Increasing the doping level changes the material's performance, primarily in terms of electron emission capability, arc starting stability, ablation resistance, and arc control accuracy.

WL10 is the earliest standard model of this type of alloy. It has good arc starting performance and medium-strength anti-burning ability. It is suitable for welding ordinary carbon steel, stainless steel and medium and low strength alloys, especially stable under DC welding conditions. Due to its balanced performance and high cost performance, it is widely used in low- and medium-end manufacturing industries.

The WL15 , an improved model, features a higher lanthanum oxide content, enhanced electron emission capability, and improved thermal shock resistance. It excels at maintaining tip shape, making it particularly well-suited for automated welding systems and pulse welding processes, significantly reducing electrode replacement frequency and improving production continuity. This model is currently the most widely used, in a wide range of applications, including aerospace, precision machinery, and medical device manufacturing.

WL20 is the model with the highest lanthanum content, with the strongest anti-burning ability and arc focusing. Even under high current and high load environment, it can still maintain good electrode shape and arc stability, especially suitable for high-temperature alloys, titanium alloys and other difficult-to-weld metal materials. This model is also recommended for welding tasks in extreme environments due to its excellent high-temperature performance, such as engine parts, nuclear power equipment, special alloy structures, etc.

It is worth noting that although these types belong to the same lanthanum tungsten electrode series, they should be selected according to multiple factors such as welding current type (DC or AC), base material type, welding method (manual or automatic), etc. In addition, the tip grinding method will also affect the arc starting effect and weld quality. Electrodes of different diameters and different angles can achieve the best welding performance.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com