Advantages of Tungsten Wire in Heating Glass Process

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:25

- Written by Zhenghua

- Hits: 174

As a high-performance functional material, tungsten wire has shown multi-dimensional technological innovation value and application advantages in the field of heating glass process. Its unique physical and chemical properties not only break through the limitations of traditional heating technology, but also promote the evolution of glass products towards intelligence and efficiency.

Read more: Advantages of Tungsten Wire in Heating Glass Process

Selection of Tungsten Wire in Glass Heating System

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:23

- Written by Zhenghua

- Hits: 174

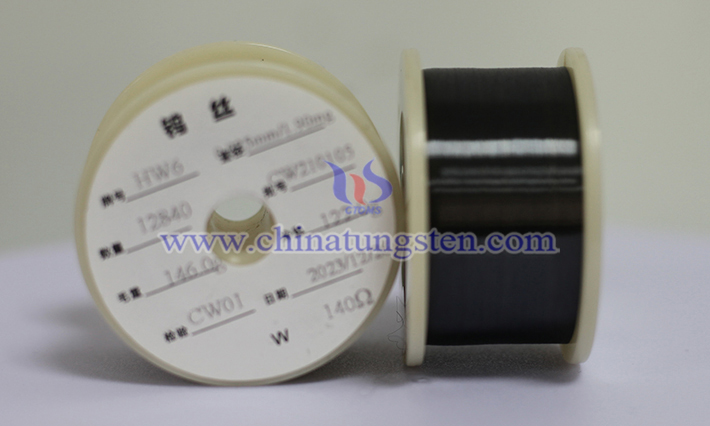

Tungsten wire has an extremely high melting point (about 3422℃) and is an ideal high temperature resistant material in glass heating system. Its resistivity is moderate, it can heat up quickly when heated, and it has good thermal stability and is not easy to deform or melt. Tungsten wire also has a low thermal expansion coefficient and can maintain structural stability at high temperatures. In addition, the chemical inertness of tungsten makes it difficult to react with glass or surrounding gases at high temperatures, extending its service life.

Read more: Selection of Tungsten Wire in Glass Heating System

Role of Tungsten Wire in Glass Heating Process

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:19

- Written by Zhenghua

- Hits: 192

The role of tungsten wire in glass heating process is mainly reflected in efficient heating, stability and precise temperature control ability, and it is an important component to ensure the quality of glass products and process efficiency.

Tungsten Wire: The Temperature Guardian in Glass Heating Equipment

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:21

- Written by Zhenghua

- Hits: 186

In processes such as glass melting, forming and sealing, heating equipment needs to operate stably at high temperatures far exceeding 1,000 degrees. When common alloy materials yield at high temperatures, tungsten wire becomes the key support in this extreme thermal field with its excellent physical properties.

Read more: Tungsten Wire: The Temperature Guardian in Glass Heating Equipment

Cleaning of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:17

- Written by Zhenghua

- Hits: 147

Tungsten wire is often used in glass heating equipment due to its high melting point and heat resistance, but long-term use will affect performance due to oxidation, contamination or residue accumulation. Cleaning of tungsten wire for glass heating is an important step to ensure heating efficiency and extend service life.

sales@chinatungsten.com

sales@chinatungsten.com