Unbonded Phase WC Tungsten Carbide Ball Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 February 2015 09:45

- Written by yewq

- Hits: 448

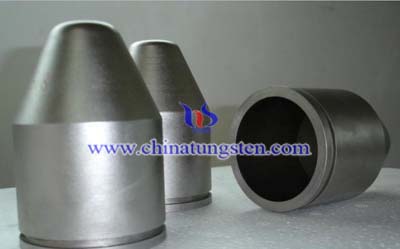

containing little or no metal binder phase. Usually Unbonded phase WC tungsten carbide ball refers metal binder phase mass fraction of less than 1%. Unbonded phase WC tungsten carbide ball with a WC-Co alloy ball unparalleled excellent wear resistance and corrosion resistance, excellent polishing and oxidation resistance, hardness and tungsten carbide ceramics collection toughness in combined with one body.

Unbonded phase WC tungsten carbide ball has great potential applications scalability. However, the melting point of pure WC up to 2860 ℃, unbonded phase WC tungsten carbide ball requires high sintering temperature (1500 ℃ ~ 2000 ℃), using conventional sintering methods are difficult to obtain fully dense block. With the development of advanced sintering technology, the current phase tungsten carbide ball unbonded preparation methods include vacuum sintering - hot isostatic pressing, pressure sintering, hot pressing, spark plasma sintering and PPC (Plasma Pressure Compaction), etc., which after 2 methods because of their special sintering mechanism can reduce the sintering temperature and heating rate is very fast and can be completed in minutes sintering, thus reducing the chance of grain growth during the sintering process, you can get a full dense ultrafine grained grain bulk material.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ultrafine Grained WC-Co Cemented Tungsten Carbide Ball Using Significance

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 February 2015 09:42

- Written by yewq

- Hits: 492

Tungsten carbide ball has high strength, high wear-resistant, high-precision, high temperature, corrosion, etc., are widely used in the oil industry and other aspects of the ball seal. When the WC grain size is reduced to below submicron, tungsten carbide ball material hardness and wear resistance, strength and toughness are improved. This ultrafine-grained WC-Co cemented tungsten carbide ball, because at the same time has a high hardness and high flexural strength, high wear resistance and toughness, is vividly called "double high" tungsten carbide ball, in order to meet a high-performance tungsten carbide ball higher and higher demands on materials industry.

Preparation of ultrafine-grained WC-Co cemented tungsten carbide ball materials adopt WC-Co powder metallurgy process, pure WC powder by high energy ball milling, so that the grain size of WC ultrafine grain reaches its hardness and strength will be a great breakthrough, sintered after obtaining a better overall performance. Many difficult to machine materials, such as aerospace materials in high temperature alloys, pump, thermal power plant ash slagging water systems, fluid seal rotating ball and other harsh environments strength and higher hardness ultrafine grained WC-Co cemented tungsten carbide ball with higher efficiency.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Many Fingers When Throw Dart

- Details

- Category: Tungsten Information

- Published on Monday, 09 February 2015 18:32

- Written by xsh

- Hits: 477

How many fingers when we throw darts? An often asked question, and it can't be answered in general. At least 3 fingers (thumb + 2), maximum all 5. All fingers should touch the barrel or the point, no finger shall touch the shaft or even the flight. A 2 finger (thumb +1) grip gives not enough control, so 3 at least. More fingers give more control in acceleration and more touch, but it makes the release more difficult as more fingers have to be coordinated. Finger coordination in release is a key point for a grip. You have to make sure that no finger can give the dart an unlucky 'kick' in release to slip it out of position at the last moment. This leads directly to the next point:

To illustrate the wide variaty of grips, some examples from the pros. Note that the grip, as written above, also partly results from the preferred barrel shape, and vice versa:

Small finger on the tip - Eric Bristow: Eric in his brilliant years used to keep his small finger wide away from the others, touching the tip of the dart. Long cylindric barrel. His grip is one variation of the basic grip, not the best, not the worst. Less talented players might struggle with it.

Three fingers - John Lowe: John uses a ton shaped rather thick and short dart, so the 3 finger grip develops natural because more fingers hardly find the space to touch the barrel. Should be considered as a standard grip for this kind of darts.

Small finger spread away - Rod Harrington: Rod uses a long and thin barrel as it becomes usual more and more when standards and accuracy of the game improve. He uses the basic grip and spreads his small finger away vertically, while the others touch the barrel. A grip that seems very logic to me, I use a similiar one, on quite the same barrel.

Holding the dart on the front end - Bob Anderson: Bob holds the dart way before the center of gravity, just a bit behind the tip. This is unusual, as most players will struggle to develop a good touch for the throw when doing this. Bob 'pulls' the dart more than he throws it. His overall throw is faster than most others and it actually seems as if he permanently is in a hurry. Lots of wrist action. He uses a pencil derived grip which seems logic with this extreme technique, and a pretty long cylindric barrel. Not the grip to recommend, but a sophisticated technique for a man who throws a very dynamic dart.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Technology in Recent Years

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 February 2015 08:51

- Written by Sherry

- Hits: 477

Refined tungsten particles become high density tungsten alloy research a new hot spot, by mechanical alloying (MA), condensation drying, chemical vapor deposition method, spray drying, sol - gel method and other methods of preparation of pre-alloyed powders and the use of appropriate technology can be made very fine powder.

In addition, the use of spray-step synthesis reaction process can be fine-grained, multi-component, pre-aggregate of tungsten alloy powder, the powder can be much lower than the melting temperature of the binder phase sintered to full density. Fan Jinglian and other craft were prepared by MA nanocrystalline tungsten alloy composite powder in a hydrogen atmosphere at atmospheric pressure sintering and densification during sintering tungsten grain growth behavior, indicating MA nanocrystalline powders can promote densification densification temperature decreases about 100 ~ 200 ℃, when the general solid-phase sintering temperature can be fine crystalline grain size of the high strength of the alloy 3 ~ 5μm.

Nano-tungsten alloy injection molding were studied in 1350 ~ 1450 ℃ showed solid phase sintering that reached full density, grain final alloy is about 3μm, tensile strength greater than 1200MPa. Other studies of tungsten alloy powder warm compaction behavior at different temperatures, indicating that temperature and pressure can significantly improve the green density, temperature and pressure radial contraction of less than room temperature blank blank radial contraction, and temperature and pressure can improve tungsten alloy microstructure. Sample cold isostatic pressing Lee letters buried in Al2O3 powder, placed in a sintering furnace heating and air 30min after pre-oxidation insulation, and then sintered at different temperatures; the results showed that the use of pre-oxidation of tungsten alloy activated sintering can reduce the sintering temperature, reducing alloy deformed and get dense tungsten alloy, while increasing the tensile strength and elongation of tungsten alloy.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Flight Protectors

- Details

- Category: Tungsten Information

- Published on Monday, 09 February 2015 18:16

- Written by xsh

- Hits: 406

Flight protectors are very useful. Their original purpose is enhancing the durability of your flights. Whenever an incoming dart strucks the flight of a dart already sticking in the board this flight is in danger of being damaged. The flight protector can almost eliminate this damage.

Another benefit is that flight protectors help keeping your dart spread -- which is a necessity (as explained above). The negative point with flight protectors is that they tend to get lost. When it pops off a dart it is usually impossible to find on the floor later -- it's just too small. Use flight protectors. You will have to spend a few additional bucks a season, but the benefit is worth the price.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com