Tungsten Alloy(a)

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 March 2015 08:45

- Written by Sherry

- Hits: 426

According to different uses, tungsten alloys are divided into tungsten carbide, heavy alloy, metal sweating materials, contact materials, electronic and electric light materials.

Tungsten doped tungsten powder is added in about 1% of silicon, aluminum and potassium oxide, in a sintered (since resistance sintering) process, volatile additives hydroxide, the formation of pores within the material, pores after processing edge axially elongated; after annealing, diffusion of pore-forming elongated parallel to the wire axis line of bubbles, this dispersion of bubbles bubble known as potassium.

Potassium tungsten bulbs impede lateral grain grow and improve high-temperature tungsten sag performance, but also to improve the room temperature ductility after recrystallization, help around the wire and transportation and storage. China doped tungsten values are in accordance with the high temperature creep WAl1, WAl2, WAl3 three kinds of grades.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Coating Material Comparision

- Details

- Category: Tungsten Information

- Published on Monday, 02 March 2015 17:08

- Written by yewq

- Hits: 430

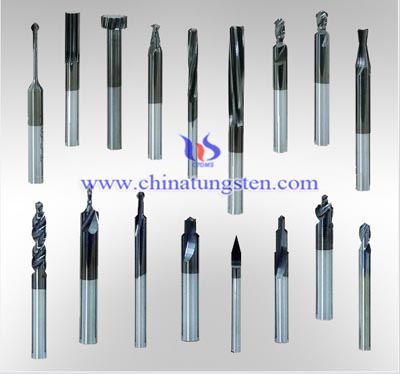

Tungsten carbide cutting tools in high-speed cutting, the blade tip temperatures up to 900 ° C, this time tungsten carbide cutting tools cutting tools wear is not only a mechanical friction and wear (behind the main form of tool wear), and adhesive wear, diffusion wear and oxidative wear (mainly in the form of the tool edge wear and crater wear), so that the cutting process can be considered as a process of physical and chemical changes of a micro-region.

Titanium tungsten carbide cutting tools is a high hardness and wear-resistant compound, has a good anti-friction and wear properties; titanium nitride lower hardness, but have a high chemical stability, and can greatly reduce the friction between the tool and the workpiece to be machined factor. From the coating process considerations, both of which are desirable coating material, but regardless of titanium tungsten carbide cutting tools or titanium nitride coating material, a single coating layer are difficult to meet the high-speed cutting tool coatings on integrated requirements. Antioxidant and anti-wear performance diffusion wear, no material can be compared with alumina (Al2O3). However, due to physical and chemical properties of the alumina matrix material with much difference, can not be made of a single alumina coating preferably coated tools. Emergence of multi-layer coatings and related technology, the coating and the substrate material can improve bond strength, while overall performance with a variety of coating materials.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Peparing Amonium Pratungstate from Tngsten Aloy scrap

- Details

- Category: Tungsten Information

- Published on Monday, 02 March 2015 14:39

- Written by zsq

- Hits: 453

Ammonium paratungstate was prepared from tungsten alloy swarf employing anodic dissolution in sodium hydroxide using a packed bed configuration followed by chemical conversion into ammonium tungstate through tungstic acid. The alkaline tungstate solution was dialysed to recover sodium hydroxide, which could be recycled to the electrolytic dissolution. The influence of anodic current density and other parameters on dissolution/recovery was studied and discussed. It was observed that a current density of 600 mA/100 g scrap could be applied when the concentration of NaOH was maintained around 2.5 M. The energy consumption for anodic dissolution was 2.14 kWh/kg W with more than 90% recovery achieved. The exhausted scrap contained an alloy of nickel and iron with a very low percentage of tungsten. APT sample prepared through anodic dissolution in NaOH was characterized.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

CVD Coated Tungsten Carbide Cutting Tools Technology Development

- Details

- Category: Tungsten Information

- Published on Monday, 02 March 2015 17:00

- Written by yewq

- Hits: 477

CVD technology since the late sixties, the coated tungsten carbide cutter has been very widely used. In the CVD technique, the preparation of the required metal source vapor deposition is relatively easy to achieve TiN, TiC, TiCN, TiBN, TiB2, Al2O3, such as single and multi-multi-layer composite carbide coating, the coating and substrate high strength, a film thickness of up to 7 ~ 9μm, CVD coating has good abrasion resistance.

In the late eighties, the United States 85% of tungsten carbide cutting tools with a coating, wherein the CVD coated tungsten carbide cutting tools accounted for 99%.

The mid-nineties, CVD coated tungsten carbide coated tungsten carbide inserts in the tool still account for more than 80%. For example, using the CVD method TiC single coat of WC-based cemented carbide substrate YW1 / TiC, and uncoated WC-based cemented carbide turning YT15 contrast. TiC single coated blade wear is much higher than YT15. CVD technology but also has its congenital defects, one process treatment temperature is high, the tool is easy to cause a decline in the flexural strength of the material; the second is the internal film tensile stress state, the use of micro-cracks easily lead; third CVD technology emissions, waste can cause industrial pollution, greater impact on the environment, and the current conflict to promote green industry, so the mid-nineties the development of high-temperature CVD technology subject to certain constraints.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Amonium Pratungstate Recovered by Filtration

- Details

- Category: Tungsten Information

- Published on Monday, 02 March 2015 14:37

- Written by zsq

- Hits: 435

The ammonium paratungstate is present in the ammoniated aqueous strip solution in an amount of from about 200 to about 300 grams per liter. Further, the ammonium paratungstate is substantially free of the impurities originally present in the brine.

The concentrated, purified ammonium paratungstate can be recovered from the ammoniated aqueous strip solution by any technique known in the art, such as evaporative crystallization, cooling the hot strip solution to allow the ammonium paratungstate to crystallize and the like. The crystallized ammonium paratungstate then can be recovered by filtration.

The filtrate of the filtration can be recycled to the two stage strip circuit of the secondary solvent extraction system where, after pH adjustment, the filtrate is reloaded with ammonium paratungstate at a temperature of from about 45C.to about 55° C. This procedure eliminates the need for additional evaporation stages and thus results in a substantial savings in equipment costs.

The ammonium paratungstate product recovered from the filtration of the strip solution can be dried using any suitable technique known in the art. Further, the ammonium paratungstate will be substantially free of impurities originally present in the brine, namely arsenic, boron, phosphorus, silica and other heavy metals.

The above described process provides an efficient and effective method for recovering concentrated, purified tungsten values (such as ammonium paratungstate) from a brine containing minor amounts of tungsten values (in the form of tungstic oxide) and substantial amounts of impurities without the use of substantial chemical costs, processing costs, or equipment modifications to obtain the desired result.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com