CVD Coated Tungsten Carbide Cutting Tools Technology Development

- Details

- Category: Tungsten Information

- Published on Monday, 02 March 2015 17:00

- Written by yewq

- Hits: 477

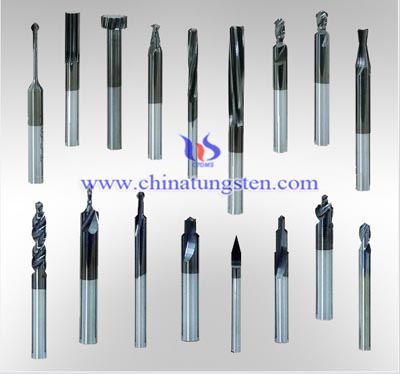

CVD technology since the late sixties, the coated tungsten carbide cutter has been very widely used. In the CVD technique, the preparation of the required metal source vapor deposition is relatively easy to achieve TiN, TiC, TiCN, TiBN, TiB2, Al2O3, such as single and multi-multi-layer composite carbide coating, the coating and substrate high strength, a film thickness of up to 7 ~ 9μm, CVD coating has good abrasion resistance.

In the late eighties, the United States 85% of tungsten carbide cutting tools with a coating, wherein the CVD coated tungsten carbide cutting tools accounted for 99%.

The mid-nineties, CVD coated tungsten carbide coated tungsten carbide inserts in the tool still account for more than 80%. For example, using the CVD method TiC single coat of WC-based cemented carbide substrate YW1 / TiC, and uncoated WC-based cemented carbide turning YT15 contrast. TiC single coated blade wear is much higher than YT15. CVD technology but also has its congenital defects, one process treatment temperature is high, the tool is easy to cause a decline in the flexural strength of the material; the second is the internal film tensile stress state, the use of micro-cracks easily lead; third CVD technology emissions, waste can cause industrial pollution, greater impact on the environment, and the current conflict to promote green industry, so the mid-nineties the development of high-temperature CVD technology subject to certain constraints.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com