Tungsten Alloy Technology in Recent Years

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 February 2015 08:51

- Written by Sherry

- Hits: 478

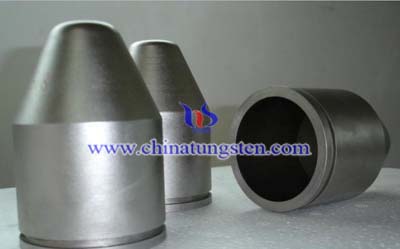

Refined tungsten particles become high density tungsten alloy research a new hot spot, by mechanical alloying (MA), condensation drying, chemical vapor deposition method, spray drying, sol - gel method and other methods of preparation of pre-alloyed powders and the use of appropriate technology can be made very fine powder.

In addition, the use of spray-step synthesis reaction process can be fine-grained, multi-component, pre-aggregate of tungsten alloy powder, the powder can be much lower than the melting temperature of the binder phase sintered to full density. Fan Jinglian and other craft were prepared by MA nanocrystalline tungsten alloy composite powder in a hydrogen atmosphere at atmospheric pressure sintering and densification during sintering tungsten grain growth behavior, indicating MA nanocrystalline powders can promote densification densification temperature decreases about 100 ~ 200 ℃, when the general solid-phase sintering temperature can be fine crystalline grain size of the high strength of the alloy 3 ~ 5μm.

Nano-tungsten alloy injection molding were studied in 1350 ~ 1450 ℃ showed solid phase sintering that reached full density, grain final alloy is about 3μm, tensile strength greater than 1200MPa. Other studies of tungsten alloy powder warm compaction behavior at different temperatures, indicating that temperature and pressure can significantly improve the green density, temperature and pressure radial contraction of less than room temperature blank blank radial contraction, and temperature and pressure can improve tungsten alloy microstructure. Sample cold isostatic pressing Lee letters buried in Al2O3 powder, placed in a sintering furnace heating and air 30min after pre-oxidation insulation, and then sintered at different temperatures; the results showed that the use of pre-oxidation of tungsten alloy activated sintering can reduce the sintering temperature, reducing alloy deformed and get dense tungsten alloy, while increasing the tensile strength and elongation of tungsten alloy.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com