Materials and Properties of Tungsten Cemented Carbide Balls

- Details

- Published on Wednesday, 10 September 2025 17:29

- Hits: 56

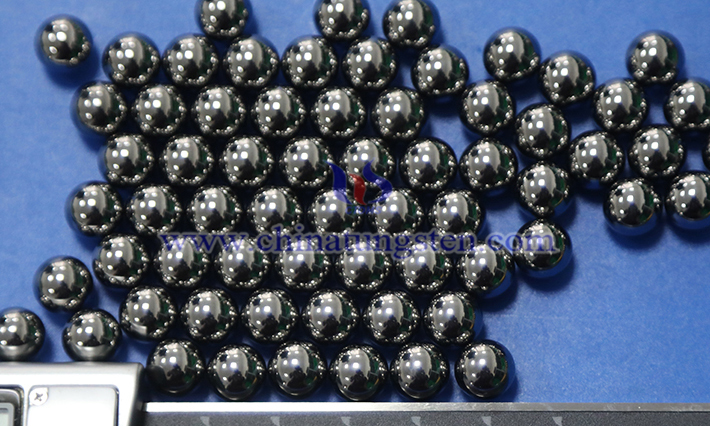

Tungsten cemented carbide balls are primarily made of tungsten carbide (WC) and a binder (such as cobalt (Co) or nickel (Ni)) through a powder metallurgy process. They exhibit high hardness, high wear resistance, corrosion resistance, and good compressive strength. The following is a detailed analysis of their materials and properties:

Characteristics of Tungsten Cemented Carbide Balls

- Details

- Published on Wednesday, 10 September 2025 17:27

- Hits: 54

Tungsten cemented carbide balls, due to their outstanding performance, are widely used in industrial applications such as precision bearings, valves, abrasive media, and metering instruments. Their high hardness and wear resistance make them outstanding in harsh environments.

What Are Tungsten Cemented Carbide Balls?

- Details

- Published on Wednesday, 10 September 2025 17:24

- Hits: 50

Tungsten cemented carbide balls are spherical components primarily made from tungsten carbide and a metal binder (such as cobalt) using a powder metallurgy process. They exhibit extremely high hardness, wear resistance, and corrosion resistance. Their unique properties have led to their widespread use in industries such as industry, manufacturing, and precision instruments.

Applications of Tungsten Alloy Discs in Target Material Fields

- Details

- Published on Tuesday, 09 September 2025 15:40

- Hits: 65

Tungsten alloy discs, with their high density, excellent high-temperature resistance, and corrosion resistance, have wide-ranging applications in the target material field, particularly excelling in advanced manufacturing techniques such as physical vapor deposition (PVD), sputtering coating, and ion beam deposition. As a high-performance target material, tungsten alloy discs play a critical role in industries such as semiconductors, solar cells, display panels, and optical coatings.

What Is Tungsten Alloy?

- Details

- Published on Tuesday, 09 September 2025 15:37

- Hits: 57

The primary component of tungsten alloy is tungsten (W), typically enhanced with elements such as nickel (Ni), iron (Fe), and copper (Cu) to optimize performance. Tungsten boasts a density of 19.35 g/cm³, significantly higher than common materials like steel (approximately 7.8 g/cm³) or aluminum (approximately 2.7 g/cm³). This high density allows tungsten alloy to provide substantial weight in a smaller volume, meeting the stringent space requirements of counterweight designs.

Applications of Tungsten Alloy Discs in Counterweight Fields

- Details

- Published on Tuesday, 09 September 2025 15:35

- Hits: 62

Tungsten alloy discs, owing to their unique physical and chemical properties, are increasingly widely used in counterweight applications, particularly excelling in high-demand scenarios such as aerospace, automotive industry, precision instruments, and sports equipment. With their high density, high strength, corrosion resistance, and excellent processability, tungsten alloys have become the preferred material for counterweights.

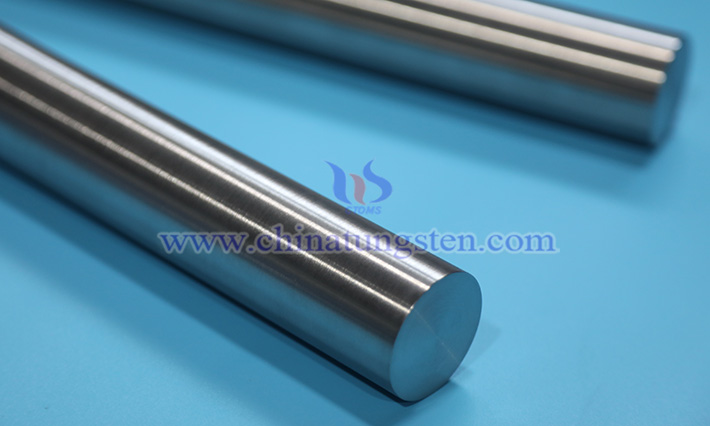

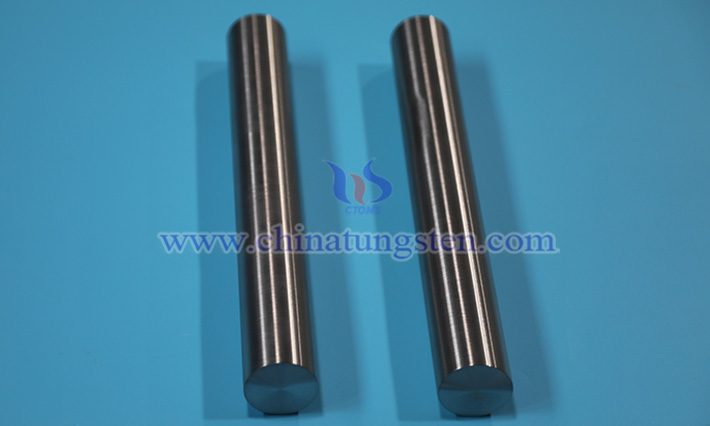

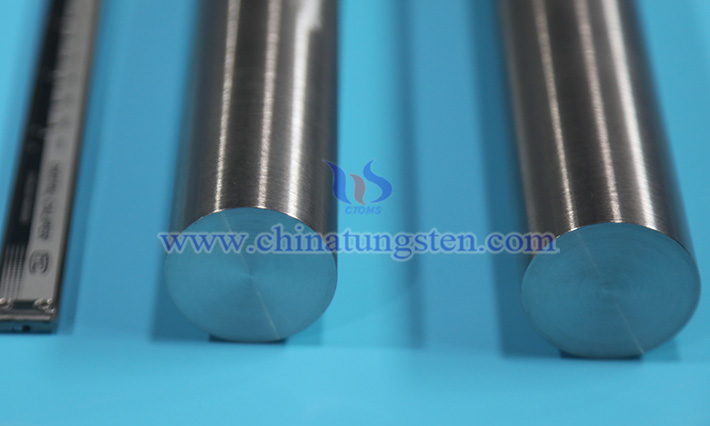

Characteristics of Tungsten Alloy Bars

- Details

- Published on Monday, 08 September 2025 11:28

- Hits: 59

Tungsten alloy, with its comprehensive advantages in density, temperature resistance, and mechanical properties, serves as a bridge connecting traditional industry with high-end manufacturing. From aerospace to medical electronics, from defense security to new energy development, tungsten alloy is continuously expanding its application boundaries through innovations in materials science. The characteristics of tungsten alloy bars include high density, high melting point, high strength, good toughness, and more.

Characteristics of Tungsten Alloy Discs

- Details

- Published on Monday, 08 September 2025 11:25

- Hits: 61

As a high-performance alloy material, tungsten alloy discs demonstrate significant application value across multiple advanced fields due to their unique physical and chemical properties. Their characteristics can be analyzed in depth from dimensions such as material essence, performance advantages, and application adaptability.

Tungsten Alloy Bar

- Details

- Published on Monday, 08 September 2025 11:20

- Hits: 61

Mentioning tungsten alloy bar often conjures images of heavy industrial equipment or cold mechanical parts. However, this material, formed by fusing tungsten with other metal elements, harbors many "hidden talents" that defy conventional understanding. Its presence has quietly permeated fields ranging from deep-sea exploration to precision instruments, serving as an unsung hero behind technological breakthroughs.

Tungsten Alloy Discs

- Details

- Published on Monday, 08 September 2025 11:17

- Hits: 50

The name "tungsten alloy disc" intuitively reflects its shape and material. Simply put, it is a disc made primarily of tungsten, combined with other metal elements such as nickel and iron through specific processes. In the field of materials science, this combination is not arbitrary but is deliberately designed to meet the demands of various complex application scenarios.

sales@chinatungsten.com

sales@chinatungsten.com