Performance Comparison of Tungsten and Copper Targets

- Details

- Published on Thursday, 11 September 2025 20:22

- Hits: 52

In the fields of semiconductor manufacturing and thin film deposition, the choice of target material significantly impacts process efficiency and product quality. Copper and tungsten targets, as two common sputtering targets, each have distinct advantages and disadvantages in terms of physical properties, chemical stability, and application scenarios.

Performance Comparison of Tungsten and Molybdenum Targets

- Details

- Published on Thursday, 11 September 2025 20:19

- Hits: 53

In the fields of thin film deposition and advanced manufacturing, the choice of target material significantly impacts process efficiency and product quality. Molybdenum and tungsten targets, as refractory metal targets, are widely used in the production of solar cells, display panels, and high-temperature coatings due to their high melting points and chemical stability.

Comparison of Tungsten Targets with Other Targets

- Details

- Published on Thursday, 11 September 2025 11:43

- Hits: 46

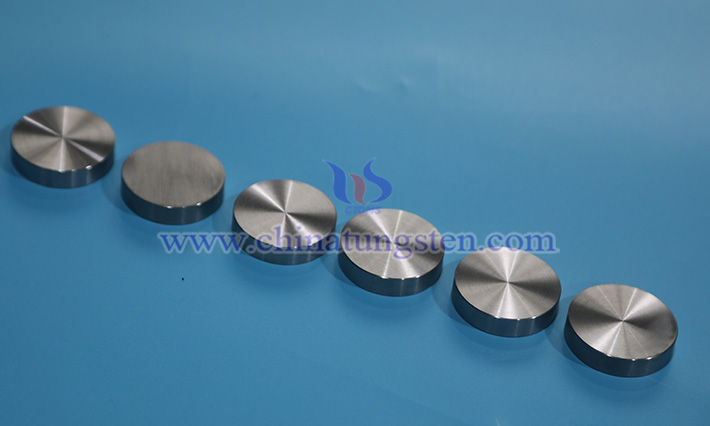

Compared to copper, aluminum, titanium, and molybdenum targets, tungsten targets exhibit significant advantages in high-temperature resistance, high density, chemical stability, mechanical strength, and thin film quality. Their stable performance in high-temperature, high-corrosion, and high-precision sputtering processes makes them the preferred material in semiconductors, medical devices, new energy, and optical coating fields.

What Is Tungsten Target?

- Details

- Published on Thursday, 11 September 2025 11:31

- Hits: 54

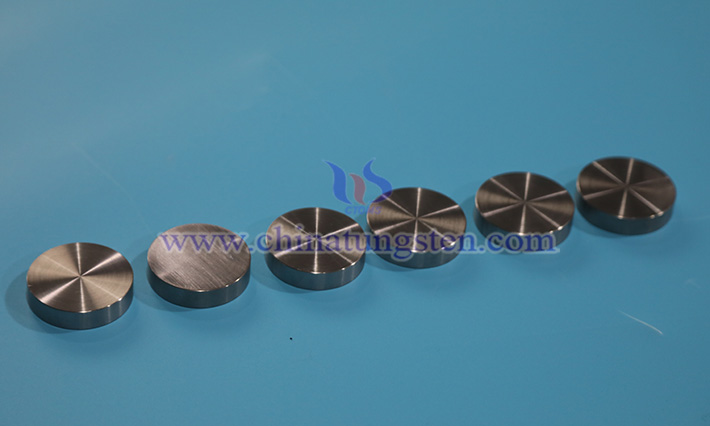

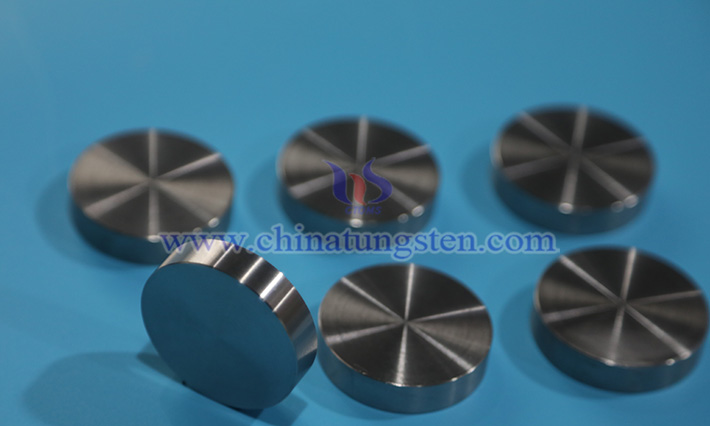

Tungsten target materials are typically based on high-purity tungsten, sometimes alloyed with elements such as titanium, tantalum, or nickel to optimize specific properties. As a refractory metal, tungsten features a high melting point and excellent hardness, enabling it to remain stable in high-temperature and high-energy environments. Its body-centered cubic crystal structure provides high density and mechanical strength, allowing it to withstand the intense ion bombardment during sputtering without deforming or fracturing. Additionally, tungsten’s good chemical stability offers excellent resistance to acids, alkalis, and other reactive gases, ensuring long-term stability in complex chemical environments.

Surface Treatment Methods for Cemented Carbide Balls

- Details

- Published on Wednesday, 10 September 2025 18:33

- Hits: 57

Cemented carbide balls surface treatment can be achieved through a variety of processes, including hard chrome plating, hard alloy overlay welding, plasma nitriding, supersonic spraying, chemical conversion coating, vapor deposition, laser surface modification, and fine grinding and polishing. Different methods focus on improving hardness, wear resistance, corrosion resistance, process complexity, and applicable scenarios. The following are some common surface treatment methods for cemented carbide balls:

Surface Treatment Technology for Cemented Carbide Balls

- Details

- Published on Wednesday, 10 September 2025 18:31

- Hits: 53

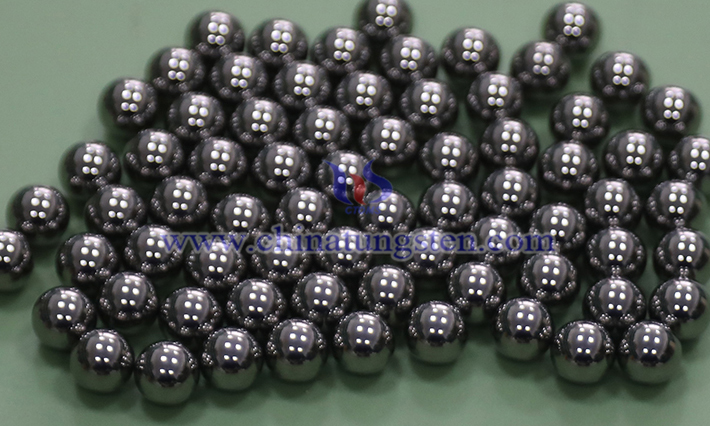

cemented Carbide balls (also known as tungsten carbide balls) are widely used in precision bearings, sealing valves, oil drilling, mining tools, and other fields due to their high hardness, wear resistance, corrosion resistance, and high temperature resistance. Surface treatment is one of the key technologies for improving the performance of cemented carbide balls.

Cemented Carbide Balls Sintering Process

- Details

- Published on Wednesday, 10 September 2025 18:29

- Hits: 53

The sintering process for cemented carbide balls is a key step in producing high-performance cemented carbide balls by combining refractory metal tungsten carbide (WC) with binder metal powders such as cobalt (Co) through powder metallurgy. Its core lies in precisely controlling parameters such as sintering temperature, time, atmosphere, and pressure to achieve a dense bond between powder particles, forming an alloy structure with excellent mechanical properties.

Heat Treatment Process of Cemented Carbide Balls

- Details

- Published on Wednesday, 10 September 2025 18:27

- Hits: 56

The heat treatment process of cemented carbide balls is mainly used to optimize their properties, such as improving hardness, wear resistance and fatigue resistance, while ensuring dimensional accuracy and surface quality.

Production Process of Tungsten Cemented Carbide Balls

- Details

- Published on Wednesday, 10 September 2025 18:25

- Hits: 53

The production process of tungsten cemented carbide balls primarily involves powder metallurgy combined with precision machining techniques. The following is an overview of the carbide ball production process:

Tungsten Cemented Carbide Balls Processing Equipment

- Details

- Published on Wednesday, 10 September 2025 18:23

- Hits: 52

Tungsten cemented carbide balls processing equipment is primarily determined by the production process, involving multiple steps such as pulverizing, mixing, pressing, sintering, and finishing. The following are common types of processing equipment and their functions, organized based on the characteristics of tungsten cemented carbide balls production:

sales@chinatungsten.com

sales@chinatungsten.com