Carbide Tool Crater Resistant Layer

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 14:11

- Written by lucy

- Hits: 471

The crater resistant layer disposed on the rake face or faces of carbide tools can be formed in various ways.

One method is compacting a mixture of powders having the desired composition of the green core and then placing a layer of a second mixture of powder having the desired proportions for the green crater-resistant layer on top of the green core and compacting both mixtures followed by sintering the resulting green compacted laminate using standard techniques to form a finished cemented carbide material.

As an alternative, previously formed, green unsintered layers of carbide materials having the desired proportions for the various layers could be laminated and compacted together followed by sintering as above to form a laminated cemented metal carbide composite substrate.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tool Binder Phase

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 14:04

- Written by lucy

- Hits: 446

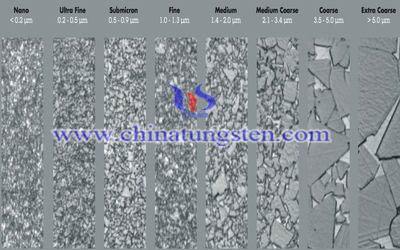

When the content of the binder phase in the cemented carbide tool is 5 to 7 mass %, the mean particle size of the hard phase is 0.6 μm to 1.0 μm, saturation magnetization is 9 to 12 μTm3/kg, the coercive force Hc is 15 to 25 kA/m, and the oxygen content is 0.045 mass % or less. Consequently, the resulting cemented carbide has high hardness and high toughness.

When the cemented carbide is used in a cutting tool, the resulting tool is excellent in wear resistance and fracture resistance. Because of low content of the binder phase, a work material made of a Ti alloy or a heat resistant alloy is less likely to be welded and thus it is possible to prevent chipping of the cutting edge due to welding and a become rough in surface roughness of the worked surface.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Advantages of Tungsten Alloy Tennis Racket Balance Weights

- Details

- Category: Tungsten Information

- Published on Tuesday, 05 May 2015 17:16

- Written by wenjing

- Hits: 474

The great performance of Tennis racket with tungsten alloy counterweight parts is reflected in high density, high tensile strength and hardness, good corrosion resistance and oxidation resistance, good mechanical properties, etc. High density is a prominent performance of tungsten alloy counterweight, the density of tungsten alloy is generally 16.5 ~ 18.6.0 g/cm ^ 3, which is more than twice that of steel density, at the same time in the increase of the weight of the volume to a minimum extent, that greatly improve the tungsten alloy counterweight design flexibility.

Environmental friendly performance is another important advantage of balancing tungsten alloy tennis racket.Tungsten alloy counterweight material has good corrosion resistance and oxidation resistance, will not cause harm to environment and human nature.It has a strict requirements on sports equipment.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Tool Construction Shortcomings

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 May 2015 13:57

- Written by lucy

- Hits: 410

Cutting tools currently in use and including carbide for cutting relatively hard metal stock combine a steel shank with a relatively small carbide cutting tip brazed to one end of the steel shank. This construction has exhibited several serious shortcomings. For example, the heat of brazing apparently changes the temper or grade of the carbide and may cause the carbide to crack. Further, brazing provides somewhat of a weak joint between the two materials, this permitting the carbide to vibrate, which may result in chipping. Also, manufacturing the cutting tool in two parts and then joining those two parts together in a brazing operation drives the cost of the device up and provides a greater chance of error in the finished product.

A further disadvantage of the two-piece carbide tip, steel shaft construction is the limited life of the cutting tool. This limited life may result in a variety of ways. First, the carbide tip can only be trimmed back approximately 1/2 inch and this inherently limits its cutting capabilities. Second, the brazing joint may fail and thereby enable the carbide insert to break away from the shaft. Third, the shaft portion supporting the insert may completely shear or seriously bend. All three of these conditions render the cutting tool inoperable and risk the danger of the steel shank tearing against the metal stock, thereby causing serious damage to the stock.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Tungsten Alloy Counterweights Applied in Cryogenic Refrigerator Ⅱ

- Details

- Category: Tungsten Information

- Published on Tuesday, 05 May 2015 17:08

- Written by wenjing

- Hits: 1676

The connecting rod to the light displacer comprises, and is preferably formed from, a high density material of at least about 15 grams such that the connecting rod is heavier than the displacer alone. Such a heavy connecting rod provides the required reciprocating mass to match the reciprocating mass of the compressor piston, and the wobbling of such a heavy mass does not result in a significant undesirable vibration. The connecting rod can be more than three times the weight of the displacer.

Heavy connecting rod is provided by forming the rod of a tungsten alloy which has a density of 17 grams per cubic centimeter. Tungsten is particularly desirable for use in the connecting rod because it has a density of greater than 15 grams per centimeter, is machinable and has the strength required for a driving element.

In a specific embodiment, the compressor piston is about 22 grams and the displacer is only about 4 grams. By using a heavy tungsten connecting rod which is 18 grams, the total weight of the displacer assembly can be made to match the weight of the compressor piston.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com