Carbide Saw Teeth Fasten Procedures

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 16:29

- Written by lucy

- Hits: 416

Carbide saws teeth are made of cemented carbide, which are suitable machine tools for hard materials cutting.

If a carbide tooth is at a saw blade, the suggested fastening procedures are listed as follows, firstly fabricated according to the saw tooth geometry being held butt-jointed to the prepared front-side abutting surface of the saw blade and then being attached to the saw blade under addition of heat along the joint between the saw blade and the carbide tooth .

To create favorable process conditions it is suggested that the carbide tooth is welded to the saw blade by means a focal spot of a laser beam extending over the whole joint length.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carbide Saw Types

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 May 2015 16:22

- Written by lucy

- Hits: 423

The initial carbide saw was a machine tool with a circular saw blade and silver soldered carbide tips. At present the most popular carbide saw types comprise as follow,

Saw with horizontal slides

One of the most commonly used type of carbide saw. With this design the saw blade is mounted on the gearbox spindle, where it slides on horizontal ways and enters horizontally into the billet. The design idea was adopting telescopic steel way covers and steel aprons to protect the vital components of the saw from high flying chips that are difficult to control.

Saws with vertical slides

In order to take over the production of this type of machine and also built it as a layer saw. The inventor had previously built vertical HSS saws with double round ways and converted them later into carbide saws.Thereafter , the saw blade for this type of saw enters vertically into the material. These saws are often used as layer saws, whereby a multitude of tubes, profiles, or bars can be simultaneously cut horizontally.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Thicknesses of Tungsten Heavy Alloy for Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 May 2015 19:17

- Written by wenjing

- Hits: 456

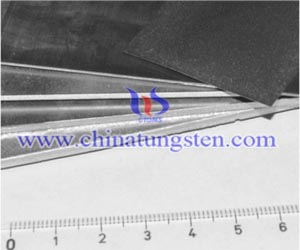

In the case of X-ray diagnostics, typical applications are collimators in the detector system and shielding parts in computer tomography. Most of these components are sheet based applications with a thickness range of about 0.1mm to 2mm. The replacement of the widely used shielding material lead (Pb) was intensified and activities on the search for substitutes have been significantly increased, the new alternative material should be tungsten heavy alloy.

Due to its high density and atomic mass, tungsten heavy alloy exhibits excellent absorption behaviour against electromagnetic radiation such as X-rays and gamma-radiation. For this reason tungsten heavy alloy materials are used for shielding applications as collimators in medical imaging diagnostics and therapy.

The fabrication of tungsten heavy alloy thin sheets with a thickness of below 1.5 mm (preferably below 0.4 mm) by tape casing technology was already reported. The near net shape produced of sheets and foils for a thickness range of below 0.1 until 4 mm was developed. In comparison to the conventional powder metallurgical fabrication of tungsten and tungsten alloy sheets for collimators, producing by pressing, sintering several rolling steps and thermal treatments, the new technology enables a nearly 100% material yield. Due to the developed technology, foil material of thickness below 0.1 and sheet material of thickness up to 3 mm can be produced .

The figure below shows tungsten heavy alloy foil and sheet material of thicknesses 0.09 to 3 mm.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Manufacture Process of Tungsten Alloy for Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 May 2015 19:19

- Written by wenjing

- Hits: 422

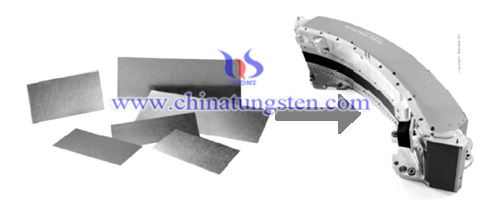

Tungsten heavy alloy materials are used for shielding applications as collimators in medical imaging diagnostics and therapy. Due to its high density and atomic mass, tungsten heavy alloy exhibits excellent absorption behaviour against electromagnetic radiation such as X-rays and gamma-radiation.

The tungsten heavy alloy collimator manfaucturing process including mixing, binding, debinding, pressing, and sintering, machining.

In comparison to the conventional powder metallurgical fabrication of tungsten and tungsten alloy sheets for collimators, producing by pressing, sintering several rolling steps and thermal treatments, the new technology enables a nearly 100% material yield. The process comprised the mixing of a tungsten alloy powder (such as: with content of 92.5 et.% W and the balance of Ni, Fe) with an organic binder, thermoplastic shaping of mixture to a green sheet material by an extrusion process, followed by debinding and sintering. The sintering step was performed in hydrogen atmosphere under liquid phase sintering conditions at a temperature range of 1450°C to 1500°C. Depend on the different needs of customers,tungsten alloy sheets can be produced into sheets and foils for a thickness range of below 0.1 until 4 mm in collimator.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cost Efficiency of Tungsten Heavy Alloy for Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 May 2015 19:13

- Written by wenjing

- Hits: 469

Due to the excellent shielding against electromagnetic radiation, tungsten based materials are typically used for collimators components in medical imaging diagnostics. However, the conventional manufacturing of pure tungsten sheet and foil material is quite expensive because of high temperature sintering and thermo-mechanical treatment.

A cost and material efficient manufacturing for tungsten based material has been developed. The new technology uses dedicated mixtures of tungsten heavy alloy powder and organic binder, which are formed and sintered to full-metallic semi-finished products. Due to the tungsten content of ≥ 90 wt.% the material exhibits excellent X-ray absorption. Furthermore the full-metallic material overcomes possible drawbacks of tungsten filled polymers with respect to aging and degradation under X-ray radiation. Sheets up to 4mm thickness and foils down to below 100μm can be produced in tight tolerances. The isotropic microstructure allows the forming of structural parts by roll bending and deep-drawing technologies.

In comparison to the conventional powder metallurgical fabrication of tungsten and tungsten alloy sheets, producing by pressing, sintering several rolling steps and thermal treatments, the new technology enables a nearly 100% material yield and further the saving of expensive thermo-mechanical processing steps. Material and cost efficient manufacturing route for tungsten heavy alloy foil and sheet material for collimators was developed. The technology established is the metal extrusion moulding where dedicated mixtures of tungsten heavy alloy powder and organic binder are formed and sintered to full-metallic semi-finished products.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com