The Manufacture Process of Tungsten Alloy for Collimator

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 May 2015 19:19

- Written by wenjing

- Hits: 423

Tungsten heavy alloy materials are used for shielding applications as collimators in medical imaging diagnostics and therapy. Due to its high density and atomic mass, tungsten heavy alloy exhibits excellent absorption behaviour against electromagnetic radiation such as X-rays and gamma-radiation.

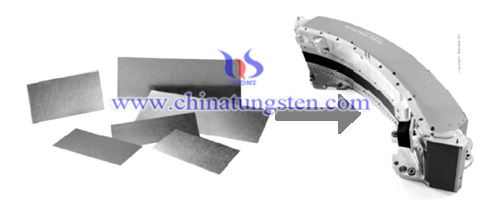

The tungsten heavy alloy collimator manfaucturing process including mixing, binding, debinding, pressing, and sintering, machining.

In comparison to the conventional powder metallurgical fabrication of tungsten and tungsten alloy sheets for collimators, producing by pressing, sintering several rolling steps and thermal treatments, the new technology enables a nearly 100% material yield. The process comprised the mixing of a tungsten alloy powder (such as: with content of 92.5 et.% W and the balance of Ni, Fe) with an organic binder, thermoplastic shaping of mixture to a green sheet material by an extrusion process, followed by debinding and sintering. The sintering step was performed in hydrogen atmosphere under liquid phase sintering conditions at a temperature range of 1450°C to 1500°C. Depend on the different needs of customers,tungsten alloy sheets can be produced into sheets and foils for a thickness range of below 0.1 until 4 mm in collimator.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com