Sapphire Dan Changjing Furnace Vacuum System

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Thursday, 21 November 2013 10:19

In particular to a Sapphire Dan Changjing  furnace vacuum system, belonging sapphire technology.That AL2O3 sapphire single crystal, with a high melting point, high hardness, good thermal conductivity, wide band through optical, electrical insulation, resistance to acid and alkali corrosion, etc., so as an important technical crystalline material, is widely used in defense, military, scientific research and a series of high technology fields, while in civilian industry also has a large number of applications, such as light emitting diodes, microelectronic circuits, optical transmission emotional, optical waveguide devices and LED energy saving.

furnace vacuum system, belonging sapphire technology.That AL2O3 sapphire single crystal, with a high melting point, high hardness, good thermal conductivity, wide band through optical, electrical insulation, resistance to acid and alkali corrosion, etc., so as an important technical crystalline material, is widely used in defense, military, scientific research and a series of high technology fields, while in civilian industry also has a large number of applications, such as light emitting diodes, microelectronic circuits, optical transmission emotional, optical waveguide devices and LED energy saving.

Sapphire crystal has a variety of production methods: Czochralski method (Czochralski crystal pulling), Kyropoulos (long grain Kjeldahl method) and temperature gradient method and other methods. But no matter of what kind of growth method, crystal growth needs to be net pumping air furnace body, a certain degree of vacuum only after the furnace is heated, the crystal raw material in the furnace after the temperature reached 2050 ° C begins to melt, and other raw materials is completely melted, there is a row of mixed melt process, before it would be crystal growth, crystal growth after the end, the need to gradually cooled until it cools completely finished. In this series of process, the furnace insulation materials, the melt crystals emit a large amount of impurities and gases exhaust the furnace if not, it will affect the quality of the crystal, which requires Sapphire Dan Changjing vacuum furnace systems by These impurities and the vacuum system of the furnace exhaust gases. The quality of the vacuum system to a stable relationship Sapphire Dan Changjing the safe operation of the furnace and the production of the crystal quality. The original design of the vacuum system used in pull-out flapper valve and metal oil diffusion pump. Metal oil diffusion pump works by heating the plate on the bottom of the vacuum oil diffusion pump for heating, vacuum oil into a heated oil vapor, oil vapor ejector use role will be within the vacuum pipe to expel air molecules and impurities outside. Heating plate damage often occur due to the interruption caused by the heating furnace Dan Changjing Sapphire crystal growth process is stopped, causing great loss. While the vacuum oil vapor will contaminate Sapphire Dan Changjing furnace furnace. This requires a secure and reliable vacuum system structure, to ensure the stability of the entire crystal growth process.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

APF in Crystal Growth Furnace

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 20 November 2013 09:31

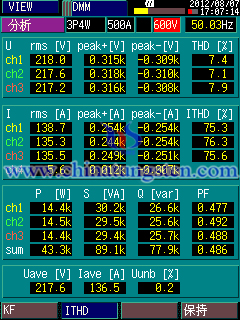

Sapphire substrates used in the production Sapphire Dan Changjing furnaces power three-phase full-controlled bridge rectifier circuit the AC to DC rectifier , smoothing through the reactor  after a constant DC current source , and then the single-phase inverter bridge , the DC current is inverted into a single phase of about 7KHz frequency current. Load from the induction coil and the compensation capacitor , which connects to the parallel resonant circuit is inductive furnace .

after a constant DC current source , and then the single-phase inverter bridge , the DC current is inverted into a single phase of about 7KHz frequency current. Load from the induction coil and the compensation capacitor , which connects to the parallel resonant circuit is inductive furnace .

In the production process of crystal growth furnace to produce large harmonic current , harmonic mainly 2,4,5,7,8 , wherein about 70% of the second harmonic . Adjusting the power system current RMS and harmonic content will be a corresponding change: when working in a small load , depending on the current of 60A, current harmonic distortion rate of 110% ; in the large work load , depending on the current of 150A and current harmonic distortion rate of 76%. In the course of crystal growth furnace will produce about 60A ~ 120A current harmonics .

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Crystal Growth Furnaces Produce A Lot of Harmonic Currents

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 20 November 2013 09:28

Crystal growth furnace harmonic currents produced by a large number of crystal growth furnace and the  surrounding equipment had a serious impact, as follows:

surrounding equipment had a serious impact, as follows:

1, The harmonic current serious impact on crystal growth furnace power supply output power quality, resulting in low yield sapphire crystal;

2, The harmonic current occupancy capacity of the power supply line, resulting in a high temperature heat supply cable, power cable temperature rise over 40 degrees;

3, The harmonic currents produced by equipment on the surrounding severely affected in the un-harmonic control, the entire workshop equipment can only be turned on simultaneously 60%, or cause power grid tripping;

4, The harmonic currents cause for isolating transformer burned out.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Asian Countries Sapphire Dan Changjing Industry Trends

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Tuesday, 19 November 2013 10:15

Although Asian countries have actively amplified Sapphire Dan Changjing production capacity , but countries  industry trends and current situation varies greatly, and some vendors to support key government forces sent exhibition , some leading polysilicon manufacturers , electronic or branched into , or by the LED related to the upstream vendor integration , showing a variety of industrial style , but also show Sapphire Dan Changjing industry has entered the fast-growing , highly competing industrial phase. Select the most positive development of the following South Korea , mainland China and Taiwan industry status and trends analysis.

industry trends and current situation varies greatly, and some vendors to support key government forces sent exhibition , some leading polysilicon manufacturers , electronic or branched into , or by the LED related to the upstream vendor integration , showing a variety of industrial style , but also show Sapphire Dan Changjing industry has entered the fast-growing , highly competing industrial phase. Select the most positive development of the following South Korea , mainland China and Taiwan industry status and trends analysis.

Korea Sapphire Dan Changjing Industry : The South Korean government has given the sapphire single crystal materials domestic supply capacity is low, and the key equipment and technology for the control of the US-Russian manufacturers , so in 2010 the ten key materials to promote the development plan (World Premier Materials development program) in selected LED sapphire single crystal material as the main R & D projects , total capital investment in 2018 will be up to 13,743 won. Fostered by the government to enhance its own vendor-specific technology and capacity advantages , the South Korean manufacturer Blaupunkt Dan Changjing production capacity in early 2011 that is promoted as the world's first . The South Korean government to help manufacturers in the near future US-Russian giant breakthrough technology patents , fast substantially increase its capacity , not only to guide their domestic manufacturers cut high growth and high profits in the emerging field , more South Korean development of LED industry reserves a solid material supply capacity.

Sapphire Dan Changjing Global Industry Status And Trends

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Tuesday, 19 November 2013 10:01

Sapphire Dan Changjing past technology and production capacity , begin with the United States and Russia, among the few leading manufacturers , forming oligopoly market structure . However, Asian manufacturers  resource betting with the government in Dachang focus support industrial investment to enhance heat production capacity substantially within a short expansion , industry outlook also appears dramatic changes . Sapphire Dan Changjing long before 2009 by the American Rubicon industry suppliers Monocrystal the oligopoly with Russia , both of which more than 50% market share . With the expansion of the LED industry and the production center of gravity toward the Asian region significantly , Asian manufacturers began to actively entered the LED is mainly upstream material Sapphire Dan Changjing fields.

resource betting with the government in Dachang focus support industrial investment to enhance heat production capacity substantially within a short expansion , industry outlook also appears dramatic changes . Sapphire Dan Changjing long before 2009 by the American Rubicon industry suppliers Monocrystal the oligopoly with Russia , both of which more than 50% market share . With the expansion of the LED industry and the production center of gravity toward the Asian region significantly , Asian manufacturers began to actively entered the LED is mainly upstream material Sapphire Dan Changjing fields.

Sapphire Dan Changjing Korean giant Sapphire Technology Company (STC) in Korea focusing policy support, the most actively expand the plant operation , at the end of 2010 can produce up to 760,000 mm, has overtaken the American past, a leading provider Monocrystal Rubicon with Russia and achieved the world's first location, and in 2011 continued to lead the expansion plan , can produce up to 1.3 million mm. Preceding three manufacturers will become the world's first breakthrough 1,000,000 mm production scale manufacturers , the total market share will reach 60%. While Taiwan's ACME ( USI photovoltaic ) , Xin crystal diamond , aquamarine Yunnan in China , Korea, Astek, were higher than the magnitude of its plant expansion relatively conservative Japanese factory Kyocera, Namiki and French materials giant Saint-Gobain, Asian manufacturers are expected capacity in 2011 will be significantly improved ranking . By country breakdown capacity ratio , can be more clearly observed Sapphire Dan Changjing global industrial chain is rapidly moving towards the trend of the Asian region .

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sapphire Substrate Foreign Enterprise Status and Development

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Monday, 18 November 2013 14:04

Because South Korea, Taiwan and mainland China and other regions LED plant since 2009, gradually  expanded metal organic chemical vapor deposition (Metal Organic Chemical Vapor Deposition, MOCVD) equipment capacity , driven by increased global demand for sapphire crystal rod , however, in 2009 the global sapphire crystal rod plant expansion production tends to be conservative , resulting in 2010 global sapphire Ingot insufficient supply of 2 -inch sapphire substrate , for example, by 2009 the price of $ 7 on the half continued to rise until the end of 2010 for about $ 30 , in this context, second half of 2010 from the world's major sapphire crystal rod plant have expansion . After sapphire crystal rod due to insufficient supply global phenomenon , the world's leading sapphire crystal rod plant expansion , although gradually , however due to varying pace of expansion of the plant , and the sapphire ingot Number of new industry is rising, this will result in 2011 the global sapphire crystal rod manufacturers do not produce changes in production capacity share .

expanded metal organic chemical vapor deposition (Metal Organic Chemical Vapor Deposition, MOCVD) equipment capacity , driven by increased global demand for sapphire crystal rod , however, in 2009 the global sapphire crystal rod plant expansion production tends to be conservative , resulting in 2010 global sapphire Ingot insufficient supply of 2 -inch sapphire substrate , for example, by 2009 the price of $ 7 on the half continued to rise until the end of 2010 for about $ 30 , in this context, second half of 2010 from the world's major sapphire crystal rod plant have expansion . After sapphire crystal rod due to insufficient supply global phenomenon , the world's leading sapphire crystal rod plant expansion , although gradually , however due to varying pace of expansion of the plant , and the sapphire ingot Number of new industry is rising, this will result in 2011 the global sapphire crystal rod manufacturers do not produce changes in production capacity share .

By Global Sapphire Ingot manufacturers do not produce energy point of view , the American Rubicon in 2009 to 2010 in the first half leading position in the world , however, the Korean factory Sapphire Technology Company (STC) due to relatively rapid pace of expansion , which was in 2010 Q3 beyond Rubicon, mainly due to government support programs in South Korea STC won financial support , help in 2011 ( including ) sapphire Ingot after its accelerated pace of expansion .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sapphire Dan Changjing Furnace Domestic Situation

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Monday, 18 November 2013 14:00

Taiwan and China manufacturers Sapphire Dan Changjing Technology Basic mainly from Russia and Ukraine. On the technical differences , the U.S. Rubicon ES2 technology used in  in 2009 the company announced the successful growth of the " world's largest sapphire crystal " , weighing up to 200kg, can be used to cut out the 12-inch sapphire substrate , Rubicon ES2 technology products claimed defect rate lower than other technologies. American Crystal Systems HEM heat exchange method is adopted , the Japanese manufacturer is more of a pulling (Czochralski Method, CZ method ) and the guided mode based method (Edge-defined Film-fed Growth, EFG method ) , Russia to KY Act (Kyropulos Method , also known as Kyropoulos ) mainly in Taiwan and China manufacturers crystal growth technique is mainly due to the Russian KY France , Russia and crystal growth technology transfer fee is low, after the large-scale production costs remain attractive .

in 2009 the company announced the successful growth of the " world's largest sapphire crystal " , weighing up to 200kg, can be used to cut out the 12-inch sapphire substrate , Rubicon ES2 technology products claimed defect rate lower than other technologies. American Crystal Systems HEM heat exchange method is adopted , the Japanese manufacturer is more of a pulling (Czochralski Method, CZ method ) and the guided mode based method (Edge-defined Film-fed Growth, EFG method ) , Russia to KY Act (Kyropulos Method , also known as Kyropoulos ) mainly in Taiwan and China manufacturers crystal growth technique is mainly due to the Russian KY France , Russia and crystal growth technology transfer fee is low, after the large-scale production costs remain attractive .

Currently sapphire CZ method is still more to the mainstream with KY law , to 2-4 inch sapphire substrate mainly based on cost factors and equipment manufacturers to develop the process , go to 6-8 inches forecast short-term probability is still low.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sapphire Crystal Crucible

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Friday, 15 November 2013 09:32

Currently used sapphire crucible furnace iridium crucible , crucible tungsten , molybdenum crucible . From a practical standpoint, iridium crucible for sapphire most polluted  is small, but the price is too expensive , the cost is high ; while tungsten and molybdenum crucible crucible relatively cheaper , but the pollution is relatively large. The general use of iridium iridium crucible crucible heating element itself , but using tungsten, molybdenum crucible crucible itself is done using less heat . Ukraine Donets Ikal-200 type of crystal growth furnace , the use of molybdenum crucible , heat shield molybdenum , tungsten heating body , at a high temperature to volatilize molybdenum and tungsten atoms. Of course, tungsten , molybdenum crucible itself to do the heating element is not without ( domestic reportedly doing very good ) , is relative , process selection and temperature field settings are very critical factor . Different crystal growth method using the crucible will be different, such as the Kyropoulos (KY) Average of tungsten crucible , heat exchange method (HEM) generally used molybdenum crucible , because the heat exchange last to fall through to take a single crystal , and the molybdenum crucible cheapest price . According crucible manufacturing process, can be divided into pressed and sintered crucible and the crucible spinning , pressed and sintered crucible of lower quality , purity, low density , relatively short life , the price is relatively cheap ; spinning crucible of higher quality, purity , density higher , longer service life , high price. It is understood that domestic crystal growth furnace is generally used to suppress sintering crucible .

is small, but the price is too expensive , the cost is high ; while tungsten and molybdenum crucible crucible relatively cheaper , but the pollution is relatively large. The general use of iridium iridium crucible crucible heating element itself , but using tungsten, molybdenum crucible crucible itself is done using less heat . Ukraine Donets Ikal-200 type of crystal growth furnace , the use of molybdenum crucible , heat shield molybdenum , tungsten heating body , at a high temperature to volatilize molybdenum and tungsten atoms. Of course, tungsten , molybdenum crucible itself to do the heating element is not without ( domestic reportedly doing very good ) , is relative , process selection and temperature field settings are very critical factor . Different crystal growth method using the crucible will be different, such as the Kyropoulos (KY) Average of tungsten crucible , heat exchange method (HEM) generally used molybdenum crucible , because the heat exchange last to fall through to take a single crystal , and the molybdenum crucible cheapest price . According crucible manufacturing process, can be divided into pressed and sintered crucible and the crucible spinning , pressed and sintered crucible of lower quality , purity, low density , relatively short life , the price is relatively cheap ; spinning crucible of higher quality, purity , density higher , longer service life , high price. It is understood that domestic crystal growth furnace is generally used to suppress sintering crucible .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sapphire Grade High-Purity Alumina

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Friday, 15 November 2013 09:29

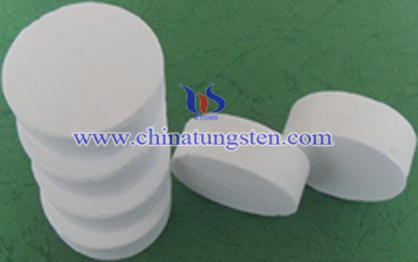

Production of sapphire crystal main raw material consumed or broken crystal alumina powder . Domestic

The current domestic production of high purity alumina mainstream technology in three ways: multiple crystallization, alkoxide solution, direct hydrolysis . Also divided into multiple crystallization of ammonium aluminum sulfate and ammonium aluminum carbonate pyrolysis pyrolysis . At present, Shandong , Shanghai , Guizhou and other places of the manufacturers , the majority of adopted this approach. Its drawback is that the metal ions and halogen element is difficult to remove , the purity can reach 4N, has basically been the limit ; said from the purity of its flaws getting bigger, generally only used in flame fusion gems , to be directly used bigger size sapphire crystal material is difficult . But if the first use made of sapphire flame fusion debris, the equivalent first conducted a crystallization purification , can be used for growing large crystals, but still can not meet the high requirements.

Alkoxide solution also divided into aluminum isopropoxide France and choline France . Choline method which is currently the largest of 4N grade alumina production methods. Hebei factory using a choline law, but almost all of its products are sold to the phosphor industry went in the crystal industry did not seem to see their sight. Dalian has several plants are basically used for aluminum isopropoxide law, and product purity are generally superior choline law , the domestic industry more accustomed YAG crystal made of the material in this way .

Direct hydrolysis is the reaction of aluminum with water directly , aluminum hydroxide, the hydrolysis process in fully enclosed organic lined environment , do not add any catalysts. This method can make the alumina 4N and 5N . At present, Guangzhou Kincaid is using this production method . Hydrolysis defect , industry insiders are unable to re- purification , the raw material is what level , made out of aluminum , that is, what level , can not go beyond the level of raw materials . However, the premise of this evaluation , the final powder product is only done so far , and if followed by the powder processed into high-density block of crystalline material , the purity can be improved beyond the level of material level .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sapphire Dan Changjing Industrial Heating Furnace Power Benefits

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Thursday, 14 November 2013 09:59

Sapphire dan changjing industrial furnace heating power has the advantage of following  .

.

1.To control the thermal field of higher quality sapphire crystal : sapphire crystal in the furnace due to crystal growth and annealing process is very sensitive to temperature changes , using high-precision power regulation system controls temperature furnace thermal field become inevitable .

2 Reliable power no-strike , sapphire crystal yield improvement : Due to adopt Kyropoulos process , single crystal furnace production cycle is long , multi- loop control technology and military power production technology and process reliability , the reliability of the power supply is guaranteed .

3.Meet future national grid management requirements: No filter reactive power compensation device , reducing equipment cost, and using high-frequency switching PWM rectifier , an increase in the power input phase-shifting transformer 12 pulse rectifier technology to ensure high power factor and low harmonic .

4 Meet requirements of the national energy saving , save electricity, reduce production costs : the use of phase-shifting rectification technology, IGBT soft switch , reducing the switching losses , in order to achieve high efficiency and low energy consumption.

5.Meet high reliable operation saving production requirements: high degree of standardization , maintainability , and can achieve high-volume standardized supporting the production, easy maintenance.

6.Consistent with national security requirements of enterprises and employment security : human security through the inspection report , long-term work in the field on the front-line staff: prevent electromagnetic radiation , to prevent the danger of high voltage , while maintaining a good grounding .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com