Using of Numerical Simulation for Growing High-Quality Sapphire Crystals by The Kyropoulos Method

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Thursday, 28 November 2013 09:27

In the present work, an advanced numerical model is suggested to analyze heat transfer and flow pattern in  sapphire crystal growth by the Kyropoulos technique. The new approach accounts for radiative heat exchange in the crystal and convection in the melt, and provides prediction of the crystallization front shape. The model allowed the analysis of several growth setup designs and selection of an optimal configuration. The numerical predictions performed with the CGSim software (www.semitech.us) agree well with available experimental data obtained in optimized crystal growth process reported for the first time.

sapphire crystal growth by the Kyropoulos technique. The new approach accounts for radiative heat exchange in the crystal and convection in the melt, and provides prediction of the crystallization front shape. The model allowed the analysis of several growth setup designs and selection of an optimal configuration. The numerical predictions performed with the CGSim software (www.semitech.us) agree well with available experimental data obtained in optimized crystal growth process reported for the first time.

Recent interest in monitoring systems requires very large optical windows that are transmitting over a wide spectral range. Some of the other requirements involve durability, high strength and robustness to withstand severe environments. Therefore, sapphire has been required for these applications. The Heat Exchanger Method (HEM)TM has been used to produce very large sapphire crystals primarily for optical applications. Crystals of 20 cm and 25 cm diameter have been produced in production for over 20 years. Presently, 34 cm diameter boules have been adopted in production, and 50 cm diameter sapphire growth is currently in development. Results of progress and characterization data of the boules will be presented.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Optical Properties of Single-Crystalline ZnO Nanowires on M-Sapphire

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 27 November 2013 09:39

Growth habits and defects in epitaxial ZnO nanowires grown from Au catalyst on (00.1) GaN/sapphire substrate using the vapor-liquid-solid (VLS) technique were studied using electron microscopy and x-ray diffraction. The results revealed presence of both horizontal (crawling-like) and vertical nanowires having similar orientation relationship to the substrate (00.1)ZnO||(00.1)GaN, [11.0]ZnO||[11.0]GaN. The crawling-like growth precedes the vertical growth, and the coalescence and overgrowth of the crawling nanowires produce a highly defective layer which separates the substrate and vertical nanorods. Transmission electron microscopy revealed a high density of planar defects in this interfacial layer. A significant density of stacking faults residing on the (0001) planes was also observed in the shorter vertical nanorods. The crawling nanowires are under residual compressive strain, whereas the vertical nanorods grow strain-free.

using the vapor-liquid-solid (VLS) technique were studied using electron microscopy and x-ray diffraction. The results revealed presence of both horizontal (crawling-like) and vertical nanowires having similar orientation relationship to the substrate (00.1)ZnO||(00.1)GaN, [11.0]ZnO||[11.0]GaN. The crawling-like growth precedes the vertical growth, and the coalescence and overgrowth of the crawling nanowires produce a highly defective layer which separates the substrate and vertical nanorods. Transmission electron microscopy revealed a high density of planar defects in this interfacial layer. A significant density of stacking faults residing on the (0001) planes was also observed in the shorter vertical nanorods. The crawling nanowires are under residual compressive strain, whereas the vertical nanorods grow strain-free.

ZnO nanowires have been synthesized using a catalyst-assisted heteroepitaxial carbothermal reduction approach on a m-sapphire substrate. Intricate and uniform arrays have been obtained with each nanowire forming an angle ∼30° with the substrate normal. Photoluminescence studies at room temperature for wavelengths between 335 and 620 nm reveal a strong single exciton peak at ∼380 nm (3.26 eV) with accompanying deep-level blueshifted emission peaks at ∼486, 490, and 510 nm. UV resonant Raman spectroscopy has been used to characterize the nanowires at room temperature with multiphonon scattering exhibiting phonon quantum confinement.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Through The Near Net Shape Crystal Growth Sapphire Production Dome of The Two Methods

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 27 November 2013 09:24

Large sapphire single crystals with the geometry of near net shape domes are grown by the gradient  solidification method (GSM). The growth is carried out in double-wall molybdenum crucibles, and perfect crystals, free of grain boundaries and scattering centers, are produced. The process is used to grow sapphire domes with different crystallographic orientations, including the optical axis. This process significantly shortens the fabrication process of the dome, thus leading to a cheaper, high-quality, product.

solidification method (GSM). The growth is carried out in double-wall molybdenum crucibles, and perfect crystals, free of grain boundaries and scattering centers, are produced. The process is used to grow sapphire domes with different crystallographic orientations, including the optical axis. This process significantly shortens the fabrication process of the dome, thus leading to a cheaper, high-quality, product.

The progress of the liquid-solid interface during crystal growth of sapphire and spinel using the heat exchanger method (HEM) has been studied and related to processing parameters. Crystal growth has thus been optimized to produce crystals with 95–100% of the material free of voids and scattering centers.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Numerical Study of Heat Transport and Fluid Flow of Melt And Gas During The Seeding Process of Sapphire Czochralski Crystal Growth

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Tuesday, 26 November 2013 09:21

For the seeding process of the Czochralski crystal growth of sapphire, the flow and temperature field with a  nonflat melt−gas interface have been studied numerically using the finite element method. The configuration usually used initially in a real Czochralski crystal growth process consists of a crucible, active afterheater, induction coil with two parts, insulation, melt, and gas. At first, the electromagnetic field produced by the radio frequency (RF) coil in the whole system and the volumetric distribution of heat inside the metal crucible and afterheater were calculated. Using this heat distribution as a source, the fluid flow and temperature field were determined in the whole system.

nonflat melt−gas interface have been studied numerically using the finite element method. The configuration usually used initially in a real Czochralski crystal growth process consists of a crucible, active afterheater, induction coil with two parts, insulation, melt, and gas. At first, the electromagnetic field produced by the radio frequency (RF) coil in the whole system and the volumetric distribution of heat inside the metal crucible and afterheater were calculated. Using this heat distribution as a source, the fluid flow and temperature field were determined in the whole system.

We have considered two cases: configuration without a gap between crucible and afterheater and with a gap, corresponding to an often used growth situation in our lab. It was shown that an active afterheater and its location with respect to the crucible influences markedly the temperature and flow field of the gas in the chamber and partly also in the melt.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Domed Sapphire Crystal Grown by The Gradient Freezing Method (GSM)

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Tuesday, 26 November 2013 09:06

Describes a sapphire single crystal growth, in a dome shape, the gradient freezing method (GSM). Molybdenum  is used in a double-walled crucible planted near net shape geometry. This significantly shortens the final size of the dome to the manufacturing process, thereby reducing costs. This process is used with a different shape (hemispherical, etc.), size (maximum diameter 6 inches) and a crystal orientation (including the optical axis) Growth dome. The growth rate of the thermal field and control the grain boundaries and prevent scattering centers is very important, and for the prevention of the action of surface tension generated geometric distortion.

is used in a double-walled crucible planted near net shape geometry. This significantly shortens the final size of the dome to the manufacturing process, thereby reducing costs. This process is used with a different shape (hemispherical, etc.), size (maximum diameter 6 inches) and a crystal orientation (including the optical axis) Growth dome. The growth rate of the thermal field and control the grain boundaries and prevent scattering centers is very important, and for the prevention of the action of surface tension generated geometric distortion.

Gradient freeze (GSM) is for large, high-quality single-crystal sapphire and calcium fluoride growth. Several growth parameters (eg, thermal gradient, stability, growth rate and the quality of the thermal field in the starting material) of the quality of the grown crystal was studied correlation. Growth of several types of defects are analyzed to clarify its nature. Crystals characterized by its crystalline and optical properties.

The Production of EFG Sapphire Ribbon for Heteroepitaxial Silicon Substrates

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Monday, 25 November 2013 14:06

A process is described for the growth of sapphire crystals in a ribbon geometry by the Edge-defined Film-fed  Growth (EFG) technique. The ribbon shaped crystals are grown for use as substrates for heteroepitaxial silicon. The apparatus, growth process, and characteristics of the grown ribbon are described. Three ribbons, 75 mm in width, are grown simultaneously. The growth rate is between 152 and 204 mm/h. A high percentage of the ribbons are free of off-oriented grains. The main defect features are “sheet” microvoids typically 5–25 μm in diameter, and “distributed” microvoids typically 0.5–2 μm in diameter. No significant difference is observed in devices fabricated in the heteroepitaxial silicon deposited on EFG and Czochralski grown substrates.

Growth (EFG) technique. The ribbon shaped crystals are grown for use as substrates for heteroepitaxial silicon. The apparatus, growth process, and characteristics of the grown ribbon are described. Three ribbons, 75 mm in width, are grown simultaneously. The growth rate is between 152 and 204 mm/h. A high percentage of the ribbons are free of off-oriented grains. The main defect features are “sheet” microvoids typically 5–25 μm in diameter, and “distributed” microvoids typically 0.5–2 μm in diameter. No significant difference is observed in devices fabricated in the heteroepitaxial silicon deposited on EFG and Czochralski grown substrates.

Epitaxial growth of GaN on sapphire substrates using an open-tube growth furnace has been carried out to study the effects of substrate orientation and transfer gas upon the properties of the layers. It has been found that for the (0001) substrates, surface appearance was virtually independent of carrier gas and of doping levels. For the (1 ¯102) substrates surface faceting was greatly reduced when He was used as a transfer gas as opposed to H2. Faceting was also reduced when the GaN was doped with Zn and the best surfaces for the (1 ¯102) substrates were obtained in a Zn-doped run using He as the transfer gas. The best sample in terms of electrical properties for the (1¯102) substrate had a mobility greater than 400 cm2 V−1 sec−1 and a carrier concentration of about 2 × 1017 cm−3. This sample was undoped and used He as the transfer gas. The best (0001) sample was also grown undoped with He as the transfer gas and had a mobility of 300cm2V−1 sec−1 and a carrier concentration of 1 × 1018 cm−3.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Interface Shapes And Thermal Fields During The Gradient Solidification Method Growth of Sapphire Single Crystals

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Monday, 25 November 2013 13:41

We present a finite-element model describing the melt-growth of cylindrical sapphire single crystals via the  gradient solidification method. The advantage of this model lies in its ability to accurately capture complex physical phenomena associated with heat transfer through the system, while remaining modest in its computational requirements. Internal radiative heat transport through the transparent crystalline phase is accounted for in our formulation, as are details of flow fields evolving in the melt during growth. Both buoyancy and surface-tension-gradient (Marangoni) driven convection effects are considered. Results show a strong dependence of the thermal field in the charge and of melt/crystal interface shapes on operating parameters such as crystal growth rate and furnace temperature gradient.

gradient solidification method. The advantage of this model lies in its ability to accurately capture complex physical phenomena associated with heat transfer through the system, while remaining modest in its computational requirements. Internal radiative heat transport through the transparent crystalline phase is accounted for in our formulation, as are details of flow fields evolving in the melt during growth. Both buoyancy and surface-tension-gradient (Marangoni) driven convection effects are considered. Results show a strong dependence of the thermal field in the charge and of melt/crystal interface shapes on operating parameters such as crystal growth rate and furnace temperature gradient.

Specifically, the large latent heat value associated with this system, coupled with enhanced radiative cooling through the crystalline phase, causes a dramatic reduction in interface curvature and position for relatively high growth rates and shallow furnace gradients. In addition, effects of fluid flow on the thermal field are shown to be unimportant in this system, even when considering growth in relatively large-diameter crucibles. Trends reported here are in general agreement with experimental observations.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sapphire Furnace Require Increasing

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Friday, 22 November 2013 10:05

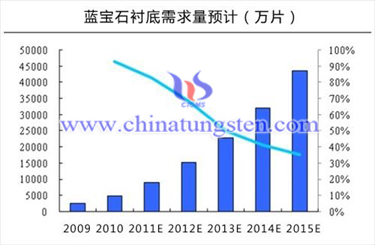

According GSC Research survey shows, sapphire price in 2009 was nine dollars, remained meager profit, even  lower than that of the traditional industry profits, low prices, were not enthusiastic about the expansion of sapphire manufacturers, the sapphire capacity began to decline, but in 2010 by the LED backlight and product penetration significantly enhance the stimulation, the sapphire substrate market demand situation, prices soaring, resulting in 2011 experienced a similar photovoltaic planning overheated investment.

lower than that of the traditional industry profits, low prices, were not enthusiastic about the expansion of sapphire manufacturers, the sapphire capacity began to decline, but in 2010 by the LED backlight and product penetration significantly enhance the stimulation, the sapphire substrate market demand situation, prices soaring, resulting in 2011 experienced a similar photovoltaic planning overheated investment.

Currently, the price of 2-inch sapphire substrate has a large drop is expected to have slowed down the progress of the majority of the project construction. Analysts predict 2013 sapphire substrate project at least Tingdiao the 50%. Sapphire return to rational investment localization Sapphire Shi Changjing furnace large size, large kilograms of high-quality, low-power, low labor ', the late domestic equipment must be price competitive with comparable technology and sufficient in order to stimulate the market again Procurement enthusiasm.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sapphire Shi Changjing Furnace The Tempered Surgery:Crystal Standard LED Upstream

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Friday, 22 November 2013 09:54

From the incandescent ban formally implementing LED << China gradually reduce the the fluorescent mercury  content roadmap >> introduction >> promulgated << semiconductor lighting energy industry planning, LED lighting will replace traditional incandescent and fluorescent lamps to become the most important way of lighting. lighting market development, and also had a role in boosting the highest value-added Sapphire and Sapphire Danchang Jing, furnace market.

content roadmap >> introduction >> promulgated << semiconductor lighting energy industry planning, LED lighting will replace traditional incandescent and fluorescent lamps to become the most important way of lighting. lighting market development, and also had a role in boosting the highest value-added Sapphire and Sapphire Danchang Jing, furnace market.

Throughout the current Sapphire Dan Zhangjing furnace market, mainly due of Sapphire Shi Zhangjing furnace technology and process mastered by foreign enterprises, and are they implemented the technology blockade, accounted for a large share of imported equipment. Crystal Grand Chinese enterprises breakthrough technology blockade, has made an important contribution to the localization in the Sapphire Shi Zhangjing furnace equipment, achieved a major breakthrough.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Purpose of The Invention Sapphire Dan Changjing Furnace And New Advantages

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Thursday, 21 November 2013 10:42

The invention aims to overcome these shortcomings, providing a furnace system to ensure stable operation of  dan changjing sapphire dan changjing furnace vacuum system.

dan changjing sapphire dan changjing furnace vacuum system.

The purpose of this utility model is achieved:

A sapphire Dan Changjing furnace vacuum system comprising vacuum channel, the vacuum channel is connected to the sapphire Dan Changjing furnace body, said lower end of said vacuum pump through molecular compound molecular pump connected to a receiver, said vacuum Pipeline and over molecular pump is disposed between the rotary gate valve, the lower end of the composite molecular pump connected to a vacuum exhaust outlet pipe, said vacuum exhaust outlet pipe is provided with a first solenoid valve, said first solenoid valve the rear exhaust pipe and the vacuum outlet is connected between said vacuum exhaust bypass pipe, the exhaust bypass pipe is provided with a second solenoid valve on the road.

Compared with the prior art, the utility model has the advantages that:

The present invention taken in the vacuum system, the composite molecular pump, an oil diffusion pump saves metal oil warm-up time, while avoiding the damage of the heating plate of the emergency shutdown resulting losses and sapphire furnace Dan Changjing The oil and gas pollution. The Sapphire Dan Changjing furnace vacuum system with Sapphire Dan Changjing furnace system can guarantee stable operation advantages.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com