Denitration and Desulfurization System Uses Tungsten Trioxide Denitration Catalyst

- Details

- Category: Tungsten's News

- Published on Monday, 06 June 2016 17:53

June 6, an eco-friendly company in China public offered of 188 million shares of stock in the New Third Board, and raised 9.964 million RMB of funds. It is reported that most of the funds will be used for the developing of flue gas desulfurization and denitration system equipment of the steel industry and the remainder of the funds will be used for the supplement of the production flow.

For a long time, China's denitration catalyst production technology has been in a monopoly situation in Europe, USA, Japan and other developed countries, the price of imported denitration equipment and tungsten trioxide denitration catalyst is very expensive, which results in flue gas denitrification costs staying high. Domestic denitration catalyst regeneration is a potential emerging market, and has not yet officially started. With the emphasis on environmental issues increasing, our state supports the innovation of desulfurization and denitration; energy saving technology research and development of scientific and technological innovation has become a hot spot, many related researchers unremitting commitment to the research of denitration catalyst, desulfurization and denitration system, and have already obtained the corresponding results, driven the Chinese overall development of flue gas denitrification technology and industry.

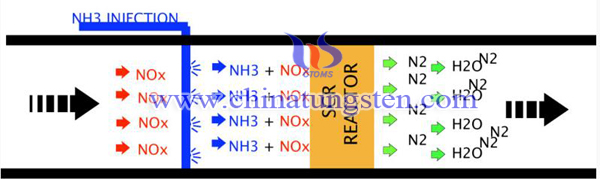

SCR denitration technology as an efficient flue gas denitrification technology, has stood out in a number of different aspects of technology with its reliable operating efficiency, also it has severed in coal-fired plants for over 30 years, played a significant role. Tungsten trioxide denitration catalyst is a core part of the SCR denitration technology, which determines the overall denitration system efficiency and economy. Wherein the component of tungsten trioxide (commonly known as tungsten oxide, tungsten anhydride), often participates into the denitration catalyst as a co-catalyst, and mainly plays a role of improving the ability to adapt to temperature and thermal stability of titanium dioxide; while avoids catalyst deactivate due to the sintering when under the high temperature for a short time; in addition, the tungsten trioxide can improve the anti-sulfide poisoning of denitration catalyst, thereby enhancing the running efficiency of the catalyst.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com