Lanthanum Tungsten Electrodes Performance And Manufacturing Methods

- Details

- Category: Tungsten Information

- Published on Thursday, 10 October 2013 14:42

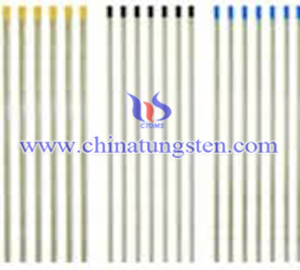

In order to take power system with excellent performance and no radioactive contamination of tungsten  electrode, tungsten trioxide powder of lanthanum oxide was added , after reduction, vertical melt , swaging , drawing obtained Φ2.7mm lanthanum tungsten electrode with the same specifications cerium tungsten, tungsten thorium power level for the electrical performance comparison , while a scanning electron microscope , measuring the electrical performance test tungsten lanthanum , cerium tungsten electrodes lanthanum , cerium content and microstructure of the distribution . The results showed that: Lanthanum tungsten electrode tungsten electrical performance than cerium , thorium tungsten ; lanthanum oxide, lanthanum tungsten migration rate , evaporation rate is low , to form a better lap dovetail organization with high temperature creep performance.

electrode, tungsten trioxide powder of lanthanum oxide was added , after reduction, vertical melt , swaging , drawing obtained Φ2.7mm lanthanum tungsten electrode with the same specifications cerium tungsten, tungsten thorium power level for the electrical performance comparison , while a scanning electron microscope , measuring the electrical performance test tungsten lanthanum , cerium tungsten electrodes lanthanum , cerium content and microstructure of the distribution . The results showed that: Lanthanum tungsten electrode tungsten electrical performance than cerium , thorium tungsten ; lanthanum oxide, lanthanum tungsten migration rate , evaporation rate is low , to form a better lap dovetail organization with high temperature creep performance.

Lanthanum tungsten electrode manufacturing method with the use of lanthanum nitrate lanthanum tungsten-coated powder preparation methods, in common with the reduction of time is prolonged, the lanthanum average particle size of the tungsten powder coated grow . The lanthanum nitrate reduction by more sensitive to the impact of time , the average increase in grain size range. The method of the present invention , lanthanum tungsten-coated powder particle size by reducing the influence of time fluctuation is small, in the particle size range within a certain time basically converge. These two different approaches are eventually encapsulated in the form of La2O3 tungsten , plays the role of grain refinement , but due to their respective decomposition temperature differences inevitably lead to the difference in outcome . The method of the present invention , the specific process conditions, the particle size range of less volatile , and in accordance with repression, burn process requirements , which can effectively reduce gasification process , helping to eliminate harmful gases nitrogen oxide pollution is a more ideal method for preparing lanthanum tungsten electrodes .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com