Tungsten Improves Electrochemical Performance of Cathode Materials for Li Batteries

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 February 2022 23:02

A study conducted by researchers at the University of Queensland has shown that the specific properties of metallic materials such as tungsten (W) and molybdenum (Mo) could improve the electrochemical properties, especially the cycle stability, of cathode materials in Li batteries. Ni–Co–Mn ternary oxide materials (NCMs) and Ni–Co–Al materials (NCAs) are widely used as cathodes in lithium ions for electric vehicles. Increasing the driving range of electric vehicles necessitates a raise of the nickel content to increase the energy density, which, however, degrades the cycle stability.

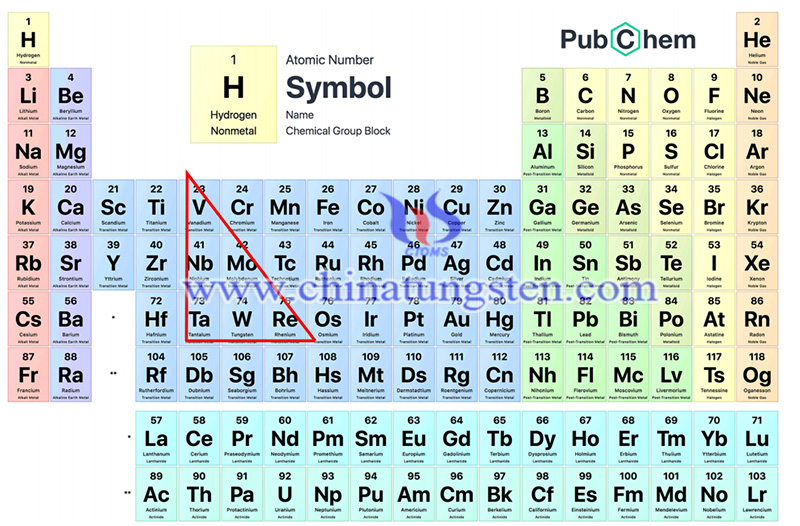

The stability improvement of tungsten and molybdenum on cathodes is based on two main features. (1) the enhanced stability of the bulk structure after doping (Mo, W, Ta, Nb) and (2) the resistance of the surface layer to the lateral reaction of the electrode/electrolyte caused by direct coating (V, W, Nb) or bulk doping.

With concerns about global warming, the demand for electric vehicles is rising rapidly. The global feet of plug-in hybrid electric vehicles and battery electric vehicles increased from 2.1 million in 2017 to 5.4 million in 2018. Currently, nickel-cobalt-manganese ternary oxide materials (NCMs) and nickel-cobalt-aluminum materials (NCAs) are considered ideal cathode materials for lithium-ion batteries (LIBs) in the short to medium term due to their high energy density, good cycling performance, good safety performance, and relatively low cost.

The development of electric vehicles suffers from "range anxiety" and there is an urgent need to expand the driving range of electric vehicles by expanding the battery capacity. However, increasing the nickel content will significantly reduce battery performance such as cycling stability (especially long-term cycling) and thermal stability. In NCM cathodes, nickel mainly contributes to increasing the specific capacity. Compared to Mn3+ and Ni3+, Co3+ has the best structural stability because it has the lowest octahedral-site stabilization energy (OSSE).

Researchers have found that tungsten plays an important role in increasing the stability of cathode materials for lithium batteries. The use of W has its own particular advantages. First, Li2WO4 or LixWO3 is a good Li+ conductor, and the use of W coating is expected to form a thin layer of Li2WO4 on the material surface, which has the potential to promote Li+ diffusion, reduce electrochemical polarization, and therefore, improve rate performance.

In addition, direct corrosion experiments have demonstrated that WO3 and Ta2O5 are more resistant to HF attack compared to other oxides such as MoO3 and Nb2O5. Therefore, doping and coating with WO3 are expected to form W-rich layers, which will reduce electrode/electrolyte side reactions to improve structural stability and thus cycling stability, especially during long-term cycling.

For NCM622, the coating was performed using WO3 and the best performance (cyclic stability) was found for 1 wt%. X-ray diffraction (XRD) results showed that the values of c/a (crystal parameter of the layered structure) and I003/I104 (intensity ratio of the two dominant crystal facets in layered structure) decreased with an increasing amount of W, indicating an increased mixing of Li/Ni because W6+ induced a transition from Ni3+ to Ni2+.

Thus, there was a stable and homogeneous WO3 film with a thickness of about 3.2 nm when the dosage was 1 wt%. This film effectively suppressed the electrode/electrolyte side reactions and greatly improved the cycling stability. In addition, an improvement in thermal stability was also observed with the W coating.

This study shows that doping/coating with W in Li batteries’ cathode materials is a promising strategy to improve the cycling stability of layered cathodes including NCM, NCA, and ultra-high nickel materials. This improvement is attributed to the specific properties of W and related elements. First, the strong bond between these elements and oxygen contributes to the higher bulk structure stability after doping. Second, the direct coating caused by doping suppresses electrode/electrolyte side reactions.

Third, the high valence (5+ or 6+) tungsten can induce the formation of Ni2+ further to the rock salt. Fourth, W doping can expand the lattice parameters, which can create a high ionic conductive layer and contribute to the rate of performance. These effects will reduce the structural degradation during cycling and thus improve the stability of the cycle.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com