The Reduction of Cobalt Doped Ammonium Paratungstate to Nanoscale W–Co Powder

- Details

- Category: Tungsten Information

- Published on Monday, 04 January 2021 22:30

In the conventional method to produce nanoscaled WC–Co material, tungsten powder is obtained from the reduction of tungsten oxides or ammonium paratungstate (APT) followed by a carburization step to obtain tungsten carbide powder. Generally, the particle size of WC–Co powder is on the micron scale. Recently, solution chemical synthesis methods such as spray conversion process and chemical co-precipitation have received increased attention for the production of nanostructured WC–Co material in order to improve the properties of sintered WC–Co materials.

Thus, a synthesis process of nanoscale W–Co powder from reduction of cobalt doped APT has been conducted. The role of cobalt in the reduction process of the Co-doped APT has also been investigated.

The experimental processes are as follow:

Cobalt hydroxide and APT are applied as precursor materials. A chemical co-precipitation approach was used through a water mediated reaction between Co(OH)2 and APT to synthesize Co-doped APT precursors.

The synthesized precursors containing water and ammonia were calcined at 220 °C for 5 h in non-flowing air. The calcined powders have mean particle size of around 250 nm, and contain a mixture of amorphous and crystalline phases. These powders still contain certain amount of water and ammonia. The heating rate of the samples of 5 °C/min from room temperature to the reduction temperature was used. We did not use a push type oven because a sudden heating of the sample leads to vigorous evaluating of ammonia and water. We also want to get homogeneous heating on the samples, remove water and ammonia and make the powders have a time to decompose during heating. To examine reduction during heating process, the sample was first heated up from room temperature to 600 °C, and then kept at this temperature for 1 min under hydrogen atmosphere. The samples were also reduced in the furnace for a period of 1, 15, 30 min at 650 °C using the same heating rate to compare reduction rate of powders with different cobalt contents. The powders were filled in the tray with a size of , and the reduction process was carried out in a tube furnace. Pure hydrogen was used as reduction atmosphere with a flow rate of 400 cm3/min.

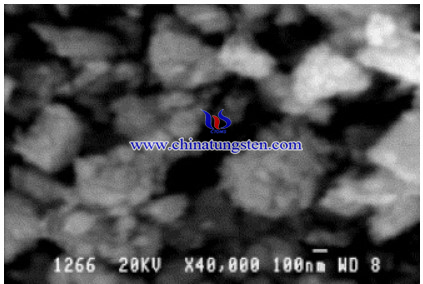

In conclusion, the result showe that nanoscale W–Co powder has a particle size of 50 nm or less can be obtained after reduction at 650 °C using W–Co precursors made by chemical synthesis. The nanostructured powders agglomerated at a sub-micron scale of 0.3–0.5 μm.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com