Realizing Potential of Molybdenum Ditelluride Nanosheet

- Details

- Category: Tungsten's News

- Published on Wednesday, 09 November 2022 20:10

Realizing the maximum potential of molybdenum ditelluride nanosheet (MoTe2 nanosheet) requires a reliable synthesis method to carefully control their phase structure and uniform large-area development. Establishing a single-stage synthesis process for MoTe2 nanosheets remains one of the biggest obstacles to their industrial application. Incorporation of large-area MoTe2 nanosheets into a variety of possible applications requires a thorough understanding of the variable phase transition and growth factors.

In this context, chemical vapor deposition (CVD) by tellurization of pre-deposited molybdenum films is a straightforward and versatile method for the fabrication of large-scale MoTe2 nanosheets. In the CVD process, 1T' and 2H-MoTe2 nanosheets can be produced by precisely controlling the kinetics and thermodynamics of MoTe2 crystal development.

(Image Credit: Tummala, P. P. et al., Advanced Materials Interfaces)

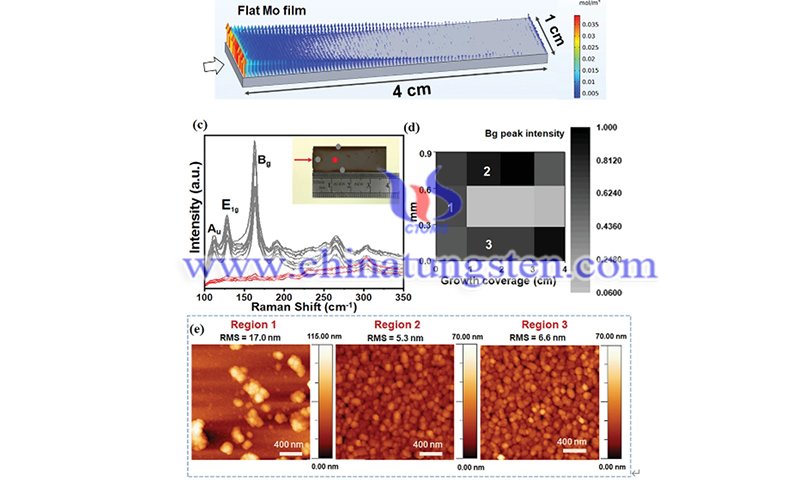

In this study, the researchers performed a series of chemical vapor deposition experiments to generate MoTe2 nanosheets as a combination of tellurium intensity gradients and substrate alignment.

Using the CVD process, the researchers demonstrated a straightforward and reproducible method for the uniform development of MoTe2 nanosheets over a wide area by analyzing the tellurization dynamics at the reaction interface. The researchers evaluated two geometric combinations of pre-deposited molybdenum sheets, namely flat and tilted tilt.

Finite element method (FEM)-based simulations were used to predict the relevant growth topologies and to relate them to the actual results of MoTe2 films produced under the same circumstances.

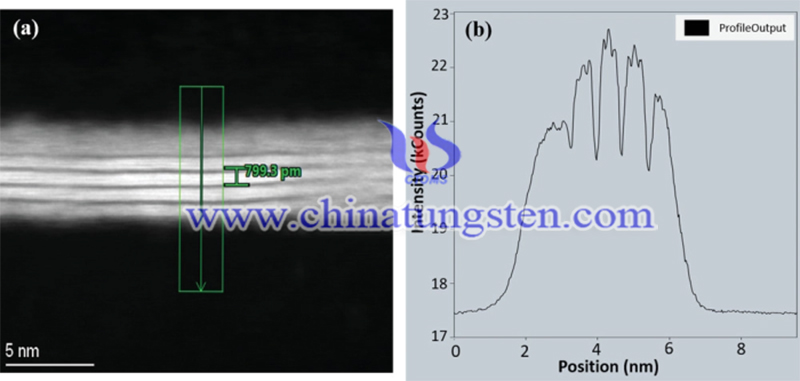

Several characterization techniques, including atomic force microscopy (AFM) and micro-Raman spectroscopy, were used to verify the orientation, cleanliness, and homogeneity of the produced molybdenum ditelluride nanosheet.

The computational results, together with experimental data, are crucial for understanding the kinetics involved in CVD-based MoTe2 formation. These synergistic modeling and laboratory results show that, in addition to the telluric quantity, the substrate tilt during development strongly determines the telluric vapor intensity gradient at the reaction site, allowing close control of the MoTe2 structure and morphology.

(Image Credit: Tummala, P. P. et al., Advanced Materials Interfaces)

Based on these results, it is reasonable to conclude that this study provides a pivot mechanism for scalable 1T' and 2H-MoTe2 incorporation into innovative nanoelectronics, optoelectronics, spectroscopy, and thermodynamic devices for applications.

In addition, this study describes a technique that may be considered an efficient, flexible and relatively easy option that allows the specification of the development and improvement of the characteristics of TMDs.

Source: https://www.azonano.com/news.aspx?newsID=39878

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com