A New Production Method to Make Tungsten Target

- Details

- Category: Tungsten's News

- Published on Thursday, 10 November 2022 10:13

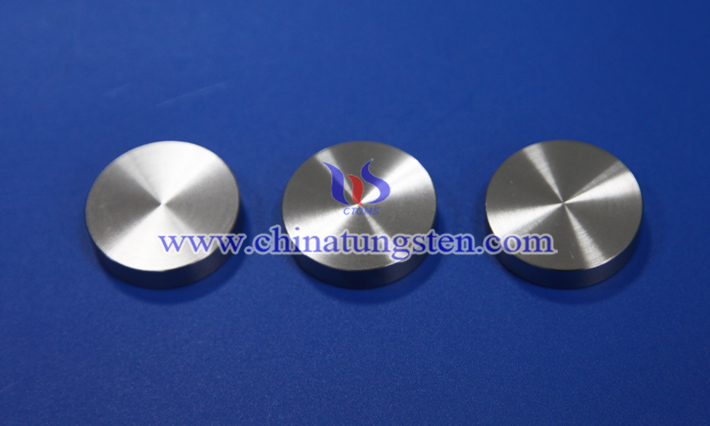

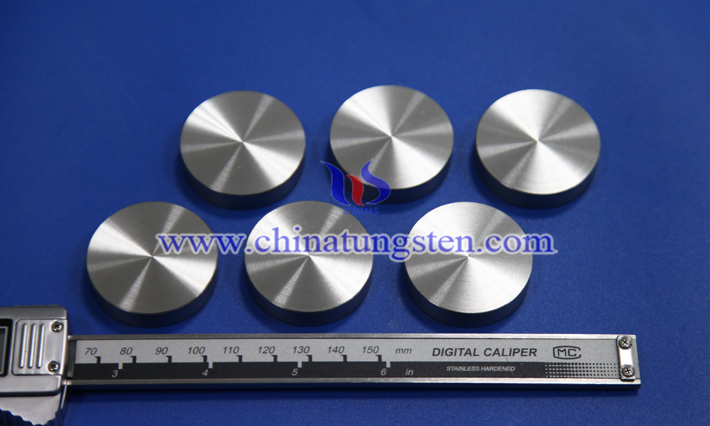

Tungsten target, also known as tungsten sputtering target, is a typical pure tungsten product with high purity, high melting point, high density, high deflection strength, good thermochemical stability, low resistance, non-toxic and non-radioactive characteristics. It is widely used in flat panel displays, solar cells, integrated circuits, automotive glass, medical equipment and other industries.

The researcher with the patent number CN102513789A provides a method for producing it and steps are as follows:

Provide target blanks; machine the surface of the blanks; put the machined blanks into a vacuum jacket and vacuumize, and the vacuuming step is done through a degassing tube; forge the blanks in the vacuum jacket; the blanks in the vacuum envelope are calendered; after the calendering, cooling is performed and the vacuum envelope is removed.

Notes on this method:

1) After the described vacuuming, also need to carry out the step of heat treatment for the first time to the vacuum envelope: after being carried out to a temperature of 200 ℃~500 ℃, carry out the insulation step. During the heating and heat preservation process, the vacuum was continuously pumped so that the vacuum degree in the vacuum envelope was at least 10^-3Pa, and then the forging step was performed on the tungsten target material blank in the vacuum envelope.

2) A second heat treatment of the blank is required before the forging step is performed on the blank in the vacuum jacket. The temperature of the second heat treatment is 900 ° C ~ 1500 ° C, and is kept at this temperature for 1h ~ 5h.

3) After the forging step is performed on the tungsten blank in the vacuum envelope and before the calendering step is performed on the blank in the vacuum envelope after forging, a third heat treatment is also performed on the blank in the vacuum envelope. The temperature of the 3rd heat treatment is 900 DEG C~1500 DEG C, and is kept at this temperature for 0.8h~1h.

Compared with the prior art, the production method has the following advantages: no mold is required, the problems of cracks and easy surface oxidation when the billet is processed and extended in the air can be avoided, and the internal structure is uniform and the grain size is consistent. The tungsten targets required by sputtering targets have the advantages of easy processing and low rejection rate.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com