First Time, Researchers Grow Ultra-Large 2D WS2 Crystals

- Details

- Category: Tungsten's News

- Published on Saturday, 29 January 2022 15:26

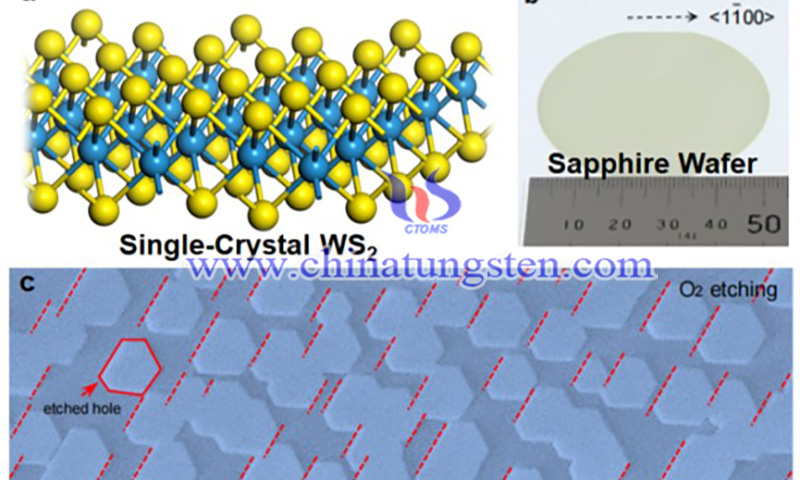

For the first time, researchers in China and Korea have grown large monolayer crystals of a 2D material known as tungsten disulphide (WS2). These crystals, grown on a sapphire substrate, are more than 3 cm in diameter and may become an alternative to silicon in next-generation semiconductor technology.

As silicon-based semiconductors are rapidly approaching the limits of their performance, researchers are seeking new materials to replace them. Two-dimensional materials such as graphene (the best known of all two-dimensional materials) and WS2 show great promise in this regard. The latter belongs to a family of materials known as transition metal dichalcogenides (TMDs), all of which have the chemical formula MX2 (where M is a transition metal such as tungsten or molybdenum and X is a brass such as sulfur, selenium, or tellurium).

TMDs have a special property. Although they are indirect bandgap semiconductors in their bulk form, they become direct bandgap semiconductors when scaled down to monolayer thickness. These monolayers absorb and emit light efficiently and can therefore be used in optoelectronic devices such as light-emitting diodes, lasers, photodetectors, or solar cells. They can also be used to make circuits for low-power electronics, low-cost or flexible displays, sensors, and even flexible electronics that can be coated on various surfaces.

Tungsten disulphide is a dry/solid lubricant powder and is one of the most lubricious substances in the world. tungsten disulphide offers excellent dry lubricity (COF: 0.03) unmatched to any other substance, including graphite or molybdenum disulfide.

However, it has so far proved difficult to grow TMDs as single-crystal structures on insulating wafer-scale substrates - a necessary condition for building ultra-large-scale high-performance semiconductor circuits. This is because the lattice of TMDs is not symmetric, resulting in an anti-parallel alignment of the material on most substrate surfaces.

Two teams led by Kaihui Liu of Peking University in China and Feng Ding of the Center for Multidimensional Carbon Materials at the Institute for Basic Science (IBS) in Korea, along with collaborators at Fudan University, have now overcome this problem. Inspired by crystal growth techniques that align nanotubes on sapphire, Liu, Ding, and their colleagues grew WS2 on a single-crystal sapphire substrate cut at an angle of just 0.1° along a specific plane.

This sapphire structure is called proximity a-surface sapphire (or a-Al2O3). The method, which the researchers call " dual-coupling guided epitaxy growth," facilitates the coupling between tungsten disulphide and sapphire edges, breaking the anti-parallel distribution of tungsten disulphide on the substrate. As a result, all TMD single crystals grown on the substrate are aligned in a single direction, after which the small single crystals coalesce to produce a larger single crystal that matches the size of the substrate.

The researchers say they have taken a major step forward in the design of 2D-based materials that could fuel the development of two-dimensional 2D semiconductors for high-end applications in electronic and optical devices.

Looking ahead, members of the team are now busy developing the next generation of techniques and theories for growing large 2D WS2 crystals. Ding told Physics World, "We will make great efforts to improve the quality of the synthesized two-dimensional materials and even control their thickness in the future."

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com