The Country's Largest Tungsten Hexafluoride Production Base Settled in Chongqing

- Details

- Category: Tungsten's News

- Published on Thursday, 31 May 2018 20:28

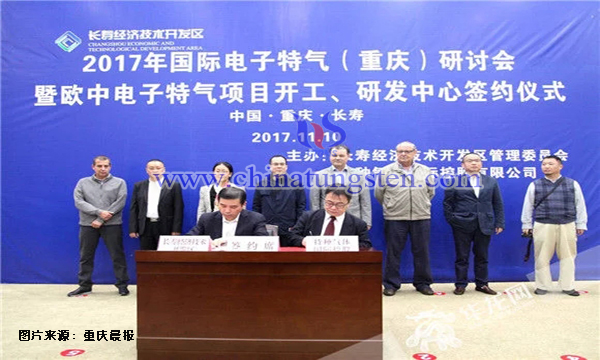

According to the Chongqing morning news, in November 10th, with the largest and most advanced six tungsten fluoride production base in the country - the European and Chinese electronic special gas project was officially started in Chongqing.

Copyright statement: This article is used only for the China Tungsten Industry Association and China Tungsten online. Any individual without written permission or without the copyright and the source is not allowed to copy or reprint without authorization. Otherwise, this website will be regarded as a tort, and the website will be investigated for its legal responsibility.

It is understood that tungsten hexafluoride is also a very important electronic specialty gas. It has been widely used in military defense, aerospace, new types of solar cells, and electronic products. Prior to this, domestic production technology relies on foreign imports. After the project is completed, the annual output value of the tungsten hexafluoride production line will reach 1 billion yuan, which can meet the current global demand of 1/3 of the market.

Tungsten hexafluoride is tungsten and fluorine to form a binary compound, chemical formula is WF6, in tungsten fluoride, tungsten hexafluoride (WF6) is the only stable and industrial production of the species. Why is tungsten hexafluoride called gas? This is because tungsten hexafluoride has unique physical and chemical properties. It is a white solid at no more than 2.0°C, a pale yellow liquid between 2.0 to 19.9°C, and a colorless gas at a density of no less than 17.5°C. It is 3.49g/cm3, 12.9 times that of air. It is one of the heaviest known gases. The molecular weight of WF6 is 297.84. The molecule has a symmetrical octahedron structure and is diamagnetic at room temperature.

The main purpose of tungsten hexafluoride is to produce high-purity tungsten, which in turn can be used to produce precision integrated circuits, LEDs, OLED displays, solar panels, and even nuclear fission equipment. The main method is high-purity metal tungsten chemical vapor deposition process, for example, WSi2 made of tungsten hexafluoride by CVD process can be used as a wiring material for large-scale integrated circuits (such as computer memory); it can be obtained through a mixed metal CVD process. The composite coating of tungsten and niobium can be used for the manufacture of X-ray emitter electrodes and solar absorbers; also, tungsten tungsten hexafluoride is required for the first wall material and tungsten divertor of ITER in the artificial sun; Tungsten hexafluoride is also often used as a raw material for semiconductor electrodes and conductive pastes in the electronics industry. It has to be said that tungsten hexafluoride has an indispensable role in high-tech fields.

At present, there are three methods commonly used for the synthesis of tungsten hexafluoride. The first one is the direct reaction of fluorine gas and tungsten to produce tungsten hexafluoride. The second is the reaction of tungsten and nitrogen trifluoride (NF3) to form tungsten hexafluoride. The third method is to produce tungsten hexafluoride by reaction with tungsten, halogen and HF. In a real sense, the tungsten hexafluoride produced by the three methods can only be considered as a primary product. It still contains a lot of impurities, and the purity is still difficult to meet industrial requirements. Therefore, the tungsten hexafluoride materials that are actually put into industrial production still need to be purified and purified. According to different uses, the purity requirements are also different, but the minimum purity standard must not be lower than 99.99% (4N), the more pure the more expensive.

Compared with the primary synthesis, the purification process of six tungsten fluoride is the key point. The purification of WF6 is dependent on the system equipment. There are many methods, such as continuous distillation, carbon purification, six tungsten chloride replacement, and so on, but there are no perfect methods in practical application. According to reports, Europe and China set up the Europe China Electronic Special Gas Research Institute in Changshou District. The first phase of investment is 50 million yuan, and the next five years plan has invested 300 million yuan. The research institute has developed six tungsten fluoride, three fluorinated nitrogen and other electronic gas projects in China. Many technologies will break the technical monopoly of foreign countries and fill the gap of domestic technology. We will wait and see that this Chinese enterprise will be put into production at an early date and will become better and better in the future production and operation.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com