Why Use Tungsten As Target In X Ray Protection?

- Details

- Category: Tungsten's News

- Published on Monday, 21 July 2014 16:08

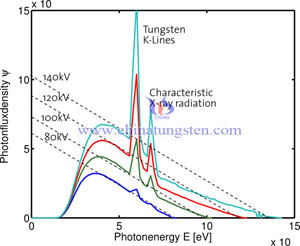

Tungsten is usually used as a target material in x-ray protection for two reasons:

1. Tungsten has a relatively high density, which could protect relatively high energy characteristic x-rays

2. Tungsten has the highest melting point of any metal, and because over 99% of the energy put into the x-ray tube to produce the beam is turned into heat energy, the ability to disparate the heat without loosing structural integrity is critical.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten market remains in the doldrums, the market mentality is difficult to improve

- Details

- Category: Tungsten's News

- Published on Monday, 21 July 2014 14:49

Tungsten market: Scheelite market remains in the doldrums, the market mentality is difficult to improve, manufacturers cash flow difficulties, purchasing enthusiasm is not high, the majority of manufacturers are currently bargain purchase a small amount of tungsten concentrate, not buy, hold stocks sidelines waiting "gold, nine silver ten "mentality is strong, tungsten scrap market, although relatively strong, but the business mentality is still disagreement, very price and pessimism coexist. Downstream tungsten smelter shipped more difficult, tungsten iron, tungsten, sodium, and other manufacturers have discontinued many difficulties manufacturers funds, procurement of raw tungsten concentrate cautious now in the traditional off-season, and even less procurement activities, expected the recent tungsten ore deal case there is no breakthrough, and the prices continue steady run.

Tungsten scrap prices continue to hold steady, the market mentality is difficult to improve

- Details

- Category: Tungsten's News

- Published on Monday, 21 July 2014 14:46

Tungsten concentrate prices temporarily stable operation, the market mentality is difficult to improve, although scrap tungsten prices relatively strong, but the business mentality is still disagreement, very price and pessimism coexist. Currently the market is still a certain demand, but the poor performance of the overall turnover is expected to more than short-term waste tungsten market will continue steady sidelines.

Tungsten scrap market continues to hold steady on the sidelines. Currently waste tungsten drill mainstream transaction price excluding tax is still concentrated in the 188-190 yuan / kg, domestic waste tungsten blade 169-171 yuan / kg, imported blade 179-181 yuan / kg. 30-40 degrees grinding tungsten scrap material concentrated near the trading price of 1.6 yuan / kWh, 50-70 degrees concentrated in the vicinity of 1.76 yuan / kWh, more than 70 degrees centered around 1.85 yuan / kWh, but the individual businesses that 1.72 yuan / kWh you can receive 80 degrees sources.

Overseas tungsten City temporarily stable operation. 18 evening MB ferrotungsten Rotterdam quote 41.5-42.5 USD / kg tungsten, ammonium paratungstate Europe quoted 360-370 U.S. dollars / metric ton, quoted in Hong Kong dollars 365-370 / metric ton, steady. With the approaching summer break in Europe, is gradually weakening overseas demand is expected to continue short-term overseas tungsten City or steady.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Circle Fish Hook for Fishing with Tungsten Alloy Sinker

- Details

- Category: Tungsten's News

- Published on Friday, 18 July 2014 18:40

Circle fish hooks with tungsten alloy are a popular live bait hook used in both saltwater and freshwater fishing applications. Circle hooks are well known for hooking more fish in the corner of the mouth making fish hook removal quicker, easier, and less stressful to the fish. T

he Tungsten alloy circle fish circle hook is a fishing hook designed so that the point is turned perpendicular to the shank to form a circular shape. The principal advantage to using circle hooks is that fish are almost never deep-hooked - research has found that circle hooks are more likely to hook a fish in the mouth rather than the gut, making them easier to remove and reducing harm to the fish.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Use the Right Fishing Tackle in Fishing Tournament

- Details

- Category: Tungsten's News

- Published on Friday, 18 July 2014 18:34

The North American Ice Fishing Championship (NAIFC) team of Captains Joe Pikulski and Myron Gilbert are on to something. Last year, the dynamic Michigan duo-both Great Lakes charter boat captains in the "off season"-took home their fourth NAIFC Team of the Year title, in nearly as many winters. Helping cement their win, the boys took two 3rd place finishes, a 5th, and various other top tens. In 2008, they dominated the highly competitive field, notching wins at Wamplers Lake, Michigan, as well as the NAIFC Championship at Boom Lake, Wisconsin.

Beyond crafty tactics, to accomplish their goals of winning tournaments, Joe and Myron's system relies on the choicest tackle. "Our go-to bait is a tungsten 5mm Wolfram jig dressed with one of several varieties of Little Atom plastics," Tungsten jigs,says Joe, fish much heavier than lead, allowing the anglers to use much smaller hooks and jig heads that thump like little heavy rocks down below the hole.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten City continued weakness in demand, the market volume was light

- Details

- Category: Tungsten's News

- Published on Friday, 18 July 2014 14:17

Tungsten market: Tungsten City continued weakness in demand, tungsten and iron smelter home enthusiasm is not high, further reducing operating rates, especially tungsten iron manufacturers cut more. Tungsten concentrate market continued market downturn, the parties' intention is not large, the market volume was light. Tungsten scrap market is relatively strong, the business mentality is still disagreement, very price and pessimism coexist. Currently the market is still a certain demand, but the poor performance of the overall transaction, expected short-term price or temporarily stabilized.

Inquiry lower tungsten ore, thinly traded

- Details

- Category: Tungsten's News

- Published on Friday, 18 July 2014 14:15

Tungsten concentrate market continued market downturn, the parties' intention is not large, the market volume was light. Tungsten ore buyers continued to weigh on prices, currently 60% of the tungsten mine in the vicinity of 1.4 yuan inquiry / kWh, but almost no turnover in this price.

State Reserve Bureau are starting this week, purchasing and storage, cobalt, molybdenum, by the stimulus, cobalt price, which has raised the price of molybdenum, tungsten, market participants are now looking forward to this season could usher in tungsten reserve, digest some stocks pressure. However, so far still has no news of tungsten Shouchu expected absence of external stimuli, the short-term weakness tungsten prices rose.

Some of the financial pressure on small manufacturers or traders are still receiving, but the volume is reduced relative to the previous lot. It is understood that more than 60 degrees wolframite now without a ticket deal more in the 1.42-1.43 yuan / kWh, with a vote of 55 degrees tungsten concentrate prices are also concentrated in the 10.5-10.6 yuan / ton.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

2014 Continued Growth in the Global Market Demand for Tungsten Carbide Cutting Tools

- Details

- Category: Tungsten's News

- Published on Thursday, 17 July 2014 19:23

The world tungsten carbide cutting tools market demand is constantly growing. That Europe, North America had stable growth, especially in Eastern Europe, a slight rebound in Asian markets, market potential, significant growth markets in Latin America, particularly Mexico.In this regard, in the past year, the tungsten carbide cutting tools market has been slow demand growth, mainly due to the increase of carbide tool life, then there is a user for the entire manufacturing process request to replace a lot of machine bed and tool. And versatile tool applications increase, a much simpler alternative to the conventional single-function tool.

Users will be more emphasis on the future production plant for research and development tool, not only in materials and surface coating technology in the field, but also in the product and its production process tool, the focus on production practices that will help them increase the tool manufacturer familiar with the field of market competitiveness.

In terms of technology updates, tungsten carbide cutting tools gradually replace speed steelcutting tools, especially circular tool.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Chinese tungsten carbide powder prices continue to decrease

- Details

- Category: Tungsten's News

- Published on Thursday, 17 July 2014 17:29

Jul 17 2014 ,The downstream customers are inactive in purchasing tungsten carbide powder because

the cemented carbide market keeps dull. Most of the downstream factories for tungsten carbide powder

only purchase from hand to mouth or produce depend on the long-term orders. Many suppliers lower their

offers slightly to promote sales.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten prices stable weak, powder business mentality weakens

- Details

- Category: Tungsten's News

- Published on Thursday, 17 July 2014 15:12

Tungsten market: weak tungsten prices stable, prices were slightly lower, some businesses intend to take the opportunity to purchase some supply lower prices, but shipments will not hold stocks, tungsten iron smelter home enthusiasm is not high, further reducing operating rates in production difficult manufacturers new orders signed, traded difficulties. Currently the mainstream price of tungsten powder and tungsten carbide market is still concentrated in the 258-260 yuan / kg, the gap between high and low at around 3 yuan / kg. Due to the recent decline in prices of tungsten concentrates, powders business mentality also will be weakened confidence in the market outlook is obviously insufficient, the overall turnover of the tungsten market subdued, the mainstream is still demand procurement.

sales@chinatungsten.com

sales@chinatungsten.com