2016.12.19-Tungsten Copper Plate Price

- Details

- Category: Tungsten Copper Price

- Published on Monday, 19 December 2016 11:46

- Hits: 1472

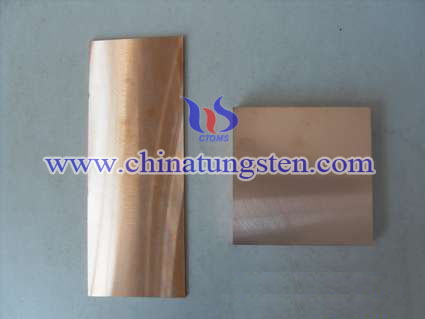

As reported by Chinatungsten Online, the current price of 85%W15%Cu tungsten copper plate of 16.5mmx28.5mmx6.3mm is $3.00 per piece EXW Xiamen, China on DEC.19, 2016.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate (AMT) Preparing Hexagonal Tungsten Oxide Ball

- Details

- Category: Ammonium Metatungstate

- Published on Thursday, 15 December 2016 16:51

- Hits: 2194

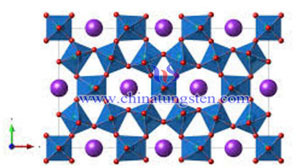

Hexagonal tungsten oxide ball (hex-WO3), which is the tungsten oxide ball with hexagonal crystal structure. Since the single crystal hexagonal tungsten oxide has an empty hexagonal space tunnel structure, the W contained compound will exit mixed valence states of W6+, W5+ and W4+ and so on, thus to make the overall compound in a balance charge state. This special structure and valence is making hexagonal tungsten oxide ball has well electro-optic effect and excellent electrical properties, thus it has widely been used in laser frequency doubling, optical signal processing, superconducting material, solid fuel cell and other fields.

Hexagonal tungsten oxide ball (hex-WO3), which is the tungsten oxide ball with hexagonal crystal structure. Since the single crystal hexagonal tungsten oxide has an empty hexagonal space tunnel structure, the W contained compound will exit mixed valence states of W6+, W5+ and W4+ and so on, thus to make the overall compound in a balance charge state. This special structure and valence is making hexagonal tungsten oxide ball has well electro-optic effect and excellent electrical properties, thus it has widely been used in laser frequency doubling, optical signal processing, superconducting material, solid fuel cell and other fields.| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Price on Dec. 15th, 2016

- Details

- Category: Ammonium Metatungstate

- Published on Thursday, 15 December 2016 10:50

- Hits: 2145

Ammonium metatungstate price with purity over 91.40% from Chinatungsten Online is 35.60 USD/KG, by Chinatungsten FOB Xiamen, Dec. 15th, 2016.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Waste Tungsten Oxide Recovering Ammonium Metatungstate (AMT)

- Details

- Category: Ammonium Metatungstate

- Published on Tuesday, 13 December 2016 17:12

- Hits: 2273

Waste tungsten oxide, including the scrapped, the not qualified which must be reworked to improve the quality indicators of tungsten trioxide, blue tungsten oxide and others. During the production, using process, or in the case of large inventories, tungsten oxide may not reach a certain specific standards due to various reasons, or directly scrapped. However, these waste tungsten oxide still contains a high content of tungsten, since the tungsten is a rare metal element, thus a more effective approach to reuse waste the tungsten is turning waste into treasure.

Waste tungsten oxide, including the scrapped, the not qualified which must be reworked to improve the quality indicators of tungsten trioxide, blue tungsten oxide and others. During the production, using process, or in the case of large inventories, tungsten oxide may not reach a certain specific standards due to various reasons, or directly scrapped. However, these waste tungsten oxide still contains a high content of tungsten, since the tungsten is a rare metal element, thus a more effective approach to reuse waste the tungsten is turning waste into treasure.| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

2016.12.12-Tungsten Carbide Rod Price

- Details

- Category: Tungsten Carbide Price

- Published on Monday, 12 December 2016 17:54

- Hits: 1724

As reported by Chinatungsten Online, the current price of YG10 tungsten carbide rod for Ø20mmx91mm is $32.00 per piece EXW Xiamen, China on DEC.12, 2016.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparing Nanometer Sheet Bismuth Tungstate

- Details

- Category: Ammonium Metatungstate

- Published on Friday, 09 December 2016 17:12

- Hits: 2176

Because of the narrow band gap (about 2.80eV), special structure and high stability and other benefits, bismuth tungstate (Bi2WO6) is a new type of environmental friendly material, which can be as the visible light photocatalyst. Bismuth tungstate has an excellent photocatalytic activity under the visible light, and can be used for degrading organic matters, such as RhB, phenol, aldehyde, antibiotics, etc; at the same time, it can catalyze the CO2 and water to generate fuel. The preparation methods of bismuth tungstate are solid reaction process, coprecipitation, sol-gel method, spray and hydrothermal method.

Because of the narrow band gap (about 2.80eV), special structure and high stability and other benefits, bismuth tungstate (Bi2WO6) is a new type of environmental friendly material, which can be as the visible light photocatalyst. Bismuth tungstate has an excellent photocatalytic activity under the visible light, and can be used for degrading organic matters, such as RhB, phenol, aldehyde, antibiotics, etc; at the same time, it can catalyze the CO2 and water to generate fuel. The preparation methods of bismuth tungstate are solid reaction process, coprecipitation, sol-gel method, spray and hydrothermal method.| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Price on Dec. 9th, 2016

- Details

- Category: Ammonium Metatungstate

- Published on Friday, 09 December 2016 10:47

- Hits: 2034

Ammonium metatungstate price with purity over 91.40% from Chinatungsten Online is 35.50 USD/KG, by Chinatungsten FOB Xiamen, Dec. 9th, 2016.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

2016.12.08-Tungsten Carbide Ball Price

- Details

- Category: Tungsten Carbide Price

- Published on Thursday, 08 December 2016 09:33

- Hits: 1674

As reported by Chinatungsten Online, the current price of YG6 tungsten carbide ball for Ø11.05mmx5mm is $26.00 per piece EXW Xiamen, China on DEC.8, 2016.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

2016.12.08-3W3 Tungsten Copper Rod Price

- Details

- Category: Tungsten Copper Price

- Published on Thursday, 08 December 2016 09:26

- Hits: 1487

As reported by Chinatungsten Online, the current price of 3W3 tungsten copper rod of Ø25mmx300mm is $120.00 per piece EXW Xiamen, China on DEC.8, 2016.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Producing Ammonium Trithiotungstate

- Details

- Category: Ammonium Metatungstate

- Published on Wednesday, 07 December 2016 16:47

- Hits: 1666

Ammonium trithiotungstate [(NH4)2WOS3] is a kind of important glucosinolates metal ammonium salt, which can generate transition-metaldichalcogenide of WS2 after the thermal decomposition, and has very well application in the synthesis of biological nitrogenase activity center - tungsten iron sulfur atom cluster compounds, semiconductor, superconducting, photoelectrochemical solar cell, battery, lubricant, electrochemical sensor, nanometer material, super capacitor, new generation of transistor and hydrogen storage and electrode material, and other respects. While it is also the precursor of coal liquefaction and heavy oil hydrogenation catalyst, as well as the raw material for manufacturing supported and non-supported type of tungsten sulfide hydrogenation catalyst.

Ammonium trithiotungstate [(NH4)2WOS3] is a kind of important glucosinolates metal ammonium salt, which can generate transition-metaldichalcogenide of WS2 after the thermal decomposition, and has very well application in the synthesis of biological nitrogenase activity center - tungsten iron sulfur atom cluster compounds, semiconductor, superconducting, photoelectrochemical solar cell, battery, lubricant, electrochemical sensor, nanometer material, super capacitor, new generation of transistor and hydrogen storage and electrode material, and other respects. While it is also the precursor of coal liquefaction and heavy oil hydrogenation catalyst, as well as the raw material for manufacturing supported and non-supported type of tungsten sulfide hydrogenation catalyst.| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com