Synthesis of Nanostructured Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 18:32

- Written by zsq

- Hits: 468

Several methods are used to form tungsten oxide films. The methods include sputtering, chemical vapor deposition, and plasma enhanced chemical vapor deposition, in which sub-atmospheric pressure must be maintained. In these methods, large, complex and expensive equipment is needed, and the methods involve significant energy consumption and relatively high operating costs. The films produced by current methods are tungsten oxide films of WO3, without suboxides, and which are colorless or faint yellow, single color films.

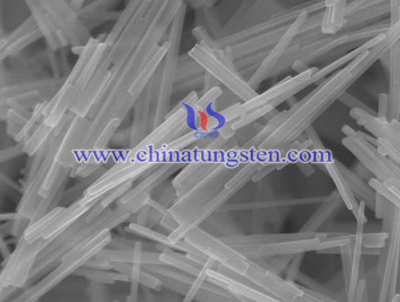

A facile and inexpensive method to produce thin films of nanostructured tungsten oxide is described. A nanocrystalline tungstite (WO3·H2O) film is spontaneously formed when a tungsten substrate is immersed in nitric acid at elevated temperatures. The resulting thin film is composed of plate-like tungstite crystals with edges preferentially directed out from the substrate surface. The tungstite can easily be transformed into WO3 by annealing. Patterned WO3·H2O/W structures can be obtained by a combination of lithographic techniques and etching. In this study, the effect of exposure time, acid concentration, and temperature on the microstructure of the films has been investigated. The potential of this inexpensive synthesis method to produce large-area coatings of nanostructured tungsten oxide as well as patterned films makes it interesting for several different applications, such as batteries, gas sensors, and photocatalysts.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Coated Tungsten Carbide Cutting Tools Dry Cutting Technology

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 11:19

- Written by yewq

- Hits: 494

Tungsten carbide cutting tools surface coating technology in recent decades in response to market demand developed surface modification technology, which effectively solve the contradiction tool material hardness, wear resistance and strength, toughness between more effectively improve the life of tungsten carbide cutting tools, the tool to obtain excellent mechanical properties, and greatly improve the machining efficiency, is widely recognized as the ideal tool material speed cutting, dry cutting technology.

Dry cutting technology is a major innovation of traditional production methods, is a new clean manufacturing technology. All kinds of super-hard, high temperature materials and coating technology development tool, created extremely favorable conditions for dry cutting technology. Coated tungsten carbide cutting tools dry coating technology has become an effective way to dry machining. Dry cutting tungsten carbide coatings play a role in the following two main aspects: on the one hand, tungsten carbide coating has a thermal conductivity than the matrix tool and workpiece material is much lower, thus weakening the thermal effect of the tool substrate ; on the other hand, it can effectively improve the friction and adhesion of the cutting process, thereby reducing the cutting heat generated.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Scrap(b)

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 08:47

- Written by Sherry

- Hits: 497

At present, China recycled metal production has maintained rapid growth for 10 consecutive years, renewable resources, recycling more than 40,000 companies, employing nearly 1,000 people, recyclables dismantling converted more than 5,000 enterprises, more than 640 distribution market. In recent years, mainly recycled metal production average annual growth of 27%, from 720,000 tons in 2000 to 7.75 million tons in 2010. By the end of 2010, non-ferrous metal has become an important part of the China Nonferrous Metals Industry, vigorously develop renewable non-ferrous metal industry, effectively easing the shortage contradiction Chinese native nonferrous mineral resources.

According to estimates, compared with the primary metal production, per ton recycled copper, recycled aluminum, secondary lead is equivalent to saving 1054 kg respectively 3443 kg, 659 kg of standard coal, water and 395 m3, 22 m3, 235 m3, reduce solid waste discharge 380 tons, 20 tons, 128 tons, recycled copper per ton, respectively, equivalent to reducing emissions of sulfur dioxide Secondary Lead 0.137 tons, 0.03 tons.

According to the China Nonferrous Metals Industry Association Recycling Metal Branch, at present, China's non-ferrous metal industry is regenerated important juncture in the restructuring, and already has a good industrial base: First, a significant effect of renewable non-ferrous metal industry restructuring, recycled metal processing park construction gradually scale, enterprises have developed rapidly, smelting and processing technology and equipment to improve the standard of significant technological progress and innovation to accelerate, formed from the scrap metal recycling, dismantling, smelting, processing and product applications complete industrial chain; the second is non-ferrous metal Product applications expanding renewable broad application prospects aluminum, secondary lead alloys, recycled copper industry has achieved good results; Third, private enterprises accounted for the main production of renewable non-ferrous metals, with mechanism of living, a new system, a strong sense of innovation and other advantages, to promote metal recycling industry has made important contributions; four is recycled metals industry has always been attached great importance to the national authorities and strong support, the current form of production, research and universities work together to promote industrial development efforts.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Brazing Equipment

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 March 2015 11:17

- Written by yewq

- Hits: 460

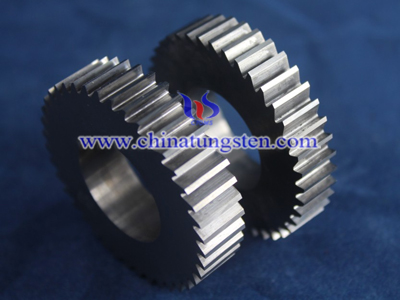

Brazing of tungsten carbide cutting tools with high hardness and wear resistance, especially at high temperatures can still maintain its high hardness, has been widely used in manufacturing various metal cutting tools. Brazed tungsten carbide is firmly connected to one of the most successful method for steel substrates, but the tungsten carbide cutting tools welding technology is an important factor in causing weld cracking.

Brazed tungsten carbide cutting tools mainly for its simple and compact structure, good rigidity, greater flexibility in use, adaptability and other characteristics, are used in precision machining, FMS, and other various metal cutting machining. Brazed tungsten carbide cutting tools are mainly using high-frequency welding brazing equipment. Induction brazing by induction heating to provide heat, or working through the induction coil is energized rather than directly on the tungsten carbide cutting tools, electrical energy transfer by induction method to tungsten carbide cutting tools, and selectively heating the surface of the part to be welded to the brazing A method of soldering temperature. Equipment brazed tungsten carbide welding process used by high-frequency induction heating equipment, high frequency induction brazing machinery and water cooling system and control system.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Electrochromic Devices Based on Porous Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 March 2015 18:18

- Written by zsq

- Hits: 550

Tungsten oxide (WO3) has been one of the most widely studied materials due to its multifunctional properties that have wide spectrum of applications in electrochromic devices, catalysers, gas sensors, optical switching devices, and so forth. Over the past three decades, intensive research has been carried out towards improving WO3-based electrochromic (EC) devices due to their important energy saving properties. A typical asymmetric EC device consists of an ion conducting (IC) layer, which also acts as a counter electrode and a WO3 electrochromic layer as the working cathode, sandwiched between two transparent conductive electrodes (TEs). When a low voltage (1–3 V) is applied across the TEs, Li+ ions from the counter electrode and electrons (e−) from the TE move to the EC WO3 layer. This double injection results in the formation of colored LixWO3 bronzes, with a controllable degree of coloration as a function of (Li ion concentration). When the applied voltages are reversed, leading to a bleached state.

Recent developments in the synthesis of transition metal oxides in the form of porous thin films have opened up opportunities in the construction of electrochromic devices with enhanced properties. In this paper, synthesis, characterization and electrochromic applications of porous WO3 thin films with different nanocrystalline phases, such as hexagonal, monoclinic, and orthorhombic, are presented. Asymmetric electrochromic devices have been constructed based on these porous WO3 thin films. XRD measurements of the intercalation/deintercalation of Li+ into/from the WO3 layer of the device as a function of applied coloration/bleaching voltages show systematic changes in the lattice parameters associated with structural phase transitions in LixWO3. Micro-Raman studies show systematic crystalline phase changes in the spectra of WO3layers during Li+ ion intercalation and deintercalation, which agree with the XRD data. These devices exhibit interesting optical modulation (up to ~70%) due to intercalation/deintercalation of Li ions into/from the WO3layer of the devices as a function of applied coloration/bleaching voltages. The obtained optical modulation of the electrochromic devices indicates that, they are suitable for applications in electrochromic smart windows.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com