Tungsten Carbide Cutting Tools Substrate Material

- Details

- Category: Tungsten Information

- Published on Monday, 16 March 2015 11:59

- Written by yewq

- Hits: 486

In conventional tungsten carbide cutting tools by adding a small amount (0.5% -3%) tungsten carbides (e.g. TaC, NbC, TIC, etc.), can significantly improve the hardness and wear resistance of tungsten carbide cutting tools without reducing its toughness, but also to improve the high temperature properties of the alloy to enhance its resistance to adhesion and proliferation-resistant wear. TIC hardness, heat resistance, bonding temperature, oxidation resistance and anti-abrasion ability than WC diffusion high, add TIC can improve these properties of the alloy, but also reduce the strength and toughness of the alloy. Add TaC and NbC can improve the alloy hardness and high temperature hardness, bonding capacity, antioxidant capacity and proliferation resistance. In addition, TaC tungsten carbide cutting tools can also improve the flexural strength, increased edge strength, strengthen the capacity and resistance to breakage edge chipping resistance. Add to WC-TIC-Co alloy suitable amount of TaC, ensure that the original heat resistance and wear resistance while also improving toughness of the alloy.

Ultrafine particles is also an increase of the base material but also improve the hardness of the material strength of the matrix method can. Ultrafine particles tungsten carbide hardness is generally 90-93HRA (higher than the average tungsten carbide 1.5-2HRA), and high-temperature hardness has been improved; the flexural strength of 2000-3500MPa, higher than the average tungsten carbide 600-80OMPa ; its toughness, chipping, even under low or intermittent cutting and other processing conditions are not easy to produce cutting edge chipping or breakage. WC grain size of fine grains generally 0.2-1.0μm, most of 0.5μm or less, a fraction to a few tenths of an ordinary tungsten carbide WC grain size. Furthermore, fine particles of the base material and the coating can also increase bonding area, to improve the bond strength, increased crack propagation resistance of the grain boundary, and thus it is possible to improve the ability of resistance to breakage tungsten carbide cutting tools.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Features of Tungsten Alloy(a)

- Details

- Category: Tungsten Information

- Published on Monday, 16 March 2015 09:58

- Written by Sherry

- Hits: 486

Heavy alloy (tungsten) is a kind of material as the substrate of tungsten (W content of 85-99%), and added Ni, Cu, Co, Mo, Cr and other elements of the alloy.

Tungsten alloy composition characteristics uses are classfied into W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, W-Ag and other major series, having a density of up to 16 .5-19.0g / cm3, and is the world known heavy alloy, it has a range of excellent features, heavy: General accounting for high 16.5-18.75g / cm3 ,, strength: tensile strength 700-1000Mpa, strong ability to absorb radiation: its capacity than Lead 30-40%, thermal conductivity coefficient: 5 times mold steel; thermal expansion coefficient is small: only iron or 1 / 2-1 / 3, good conductive properties of steel; has good weldability and formability . Given the high proportion of these alloys have excellent features, it is widely used in the aerospace, aviation, military, oil drilling, electrical instrumentation, medical and other industries.

Medical tungsten alloy ray mask material: tungsten alloy (heavy alloy) multi-leaf collimators (MLC), the thickness of 2.0-3.8mm, flatness board 0.05mm; tungsten alloy (heavy alloy; tungsten collimator ) protective tank - radioactive for medical mask on the wall; tungsten needle masks - masks for medical radioactive liquid; tungsten alloy memory - used to store radioactive material cans, boxes and other containers; quasi collimator - for medical linear accelerator and cyclotron; tungsten alloy container - for 60Co radiation therapy machine mask; γ camera tungsten collimator.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Coating Material

- Details

- Category: Tungsten Information

- Published on Friday, 13 March 2015 10:24

- Written by yewq

- Hits: 491

Tungsten carbide cutting tools surface coating material must have a high hardness, wear resistance, chemical stability, does not react chemically with the workpiece material, heat resistant to oxidation, low coefficient of friction, as well as other requirements attached to a solid substrate. Clearly, a single coating material is difficult to meet the above requirements. So tungsten carbide coating material has been coated with a single initial TiC, TiN hard coatings, experienced TiC, TiN, AlO composite coating and development stage TiCN, TiAlN multiple composite coating film now has a diamond-coated layer, the tool coating performance has been greatly improved.

Tungsten carbide cutting tools coating materials, processes the most mature and most widely used is TiN. But TiN and TiC matrix bond strength is less than a coating easy to peel off, and the hardness of TiC is not as high, at higher cutting temperatures easily oxidized film is ablated. TiC coating has high hardness and wear resistance, oxidation resistance , but brittle, the impact of intolerance. TiC and TiN, TiCN both the advantages of the two materials, which in the coating process can be continuously changed by C, N component nature of control TiCN, and a multilayer structure formed of different components, can reduce the internal stress of the coating, to improve the toughness increase the thickness of the coating of tungsten carbide cutting tools to prevent crack propagation and reduce chipping.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Brazed Tungsten Carbide Cutting Frequency Welding Factor

- Details

- Category: Tungsten Information

- Published on Friday, 13 March 2015 10:29

- Written by yewq

- Hits: 498

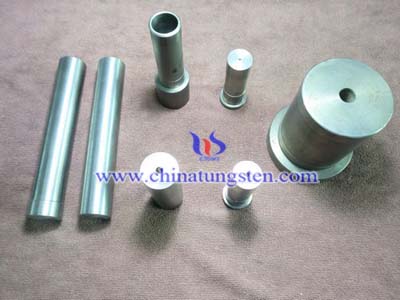

Brazed tungsten carbide cutting tools for its simple and compact structure, good rigidity, greater flexibility in use, adaptability and other characteristics, are used in precision machining, FMS, and other various metal cutting machining. tungsten carbide blade and shank is often used for brazing high frequency induction brazing and soldering flame. Because of the high frequency brazing method which has a heating speed, temperature, concentration, part distortion characteristics such as tungsten carbide welding process, a common method.

Commonly used tungsten carbide inserts tungsten carbide have YT5, YT15, YT30, YG3X, YN, etc. The physical properties of its linear expansion coefficient greater impact on weldability. Coefficient of linear expansion (4.2 ~ 7) × 10- 6 / ℃, tungsten carbide thermal conductivity of 0.08 to 0.21 cal / cm · sec · deg, which are important cause welding stress. tungsten carbide brazing filler metal of choice for HL105 solder. Because HL105 solder has good wetting and high weld strength, while HL105 solder temperature plastic, solder varied shapes, so HL105 (BCu58ZnMn) solder is the best brazed tungsten carbide cutting tools braze welding of materials. Solder before use to wipe with alcohol. tungsten carbide cutting tools at high frequency brazing flux if not fit, easy to form a brittle compound in solder joints junction. Therefore, when the brazing flux to be complex. Chemical composition of the high-frequency flux brazing of tungsten carbide cutting tools used are dehydrated borax (50%), boric acid (35%) and dehydrated potassium fluoride (15%).

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Scrap(d)

- Details

- Category: Tungsten Information

- Published on Friday, 13 March 2015 09:11

- Written by Sherry

- Hits: 507

Accelerate the development of "urban minerals"

"Eleventh Five-Year" period, non-ferrous metal industry basically solved the scale of the problem, "1025" period, non-ferrous metal industry specification will mainly solve the problem, continue to become bigger and stronger on the road to sustainable development.

The party's seventh session of the Fifth Plenary Session: To accelerate the construction of resource-saving and environment-friendly society, to improve the level of ecological civilization, and actively respond to global climate change, to develop the loop economy, enhance resource conservation and management. Intensify environmental protection, strengthen ecological protection and disaster prevention and mitigation system, enhance capacity for sustainable development. Non-ferrous metal is "urban minerals" an important part. The State Council issued the "non-ferrous metals industry restructuring and revitalization plan" is also clear: focus their efforts on recycling, vigorously develop the loop economy, accelerate the construction of the whole society, non-ferrous metal recycling system. This fully shows that "1025" period, non-ferrous metal industry promising.

China Nonferrous Metals Industry Association Recycling Metal Branch, the "Eleventh Five-Year" period, non-ferrous metal industry basically solved the scale of the problem, "1025" period, non-ferrous metal industry specification will mainly solve the problem, continue in sustainable development bigger and stronger on the road.

According to regenerate the "Eleventh Five-Year" period of non-ferrous metal industry development momentum in 2015, our main recycled metal production will reach 12 million tons, of which 3.8 million tons recycled copper, 5.8 million tons of recycled aluminum, secondary lead 2.4 million tons, accounting for then the proportion of copper, aluminum, lead production, respectively, 40%, 30%, 40%. Recycled copper, recycled aluminum industry form a group of more than 100,000 tons of large-scale enterprises, the secondary lead industry to form a group of more than 50,000 tons of large-scale enterprises. The top 10 industrial enterprises reached more than 50% concentration, fostered a number of key areas of industry cluster development, which accounted for more than 80 percent capacity.

According to reports, "1025" period, China will further optimize the layout of non-ferrous metal industry. Key support in Zhejiang, Guangdong, Shandong, Tianjin, Jiangxi and other regional development recycled copper, support Guangdong, Zhejiang, Chongqing, Shanghai, Henan and other regional development recycled aluminum, support, Anhui, Henan, Shandong, Jiangsu, Hubei and other areas of development of secondary lead. Meanwhile, in the Pearl River Delta, Yangtze River Delta, Bohai Sea and the Chengdu-Chongqing Economic Zone and other places to support expansion 200,000 tons recycled copper project 6-8, 200,000 tons of recycled aluminum items 8-10. In the north, central, northeast, the Yellow River Delta and other regions to support expansion from 50,000 to 100,000 tons recycled copper project 10, from 50,000 to 100,000 tons of recycled aluminum project 15, more than 50,000 tons Secondary Lead Project 10. Renovation and expansion of local support in the northwest 50,000 tons recycled copper project 2, 50,000 tons of recycled aluminum project 3.

By 2015, China's non-ferrous metal industry as a whole will significantly improve the standard of technical equipment. Dismantling the universal application of mechanization, the use of standards to further improve the classification. Metal recycling facility complete melting furnace and ancillary to the direction of the development, production and advanced technology can reach more than 80%. "1025" period will focus on breakthroughs in the field of renewable non-ferrous metal scrap non-ferrous metal pretreatment, smelting and energy saving technology and key equipment, a key technology to solve a number of metal recycling and energy saving technologies through technology integration and demonstration gradually establish a renewable non-ferrous metal industry, science and technology innovation system.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com