Fe-doped Tungsten Oxide Thin Films

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 16:54

- Written by zsq

- Hits: 566

Tungsten oxide (WO3) is an electrochromic material which has been widely used as the basis for electrochromic-based devices such as displays and light modulating windows. Numerous methods are known for depositing tungsten oxide coatings onto a substrate. Vacuum deposition methods such as sputtering and evaporation are the most commonly used processes, although solution deposition methods are known as well. These solution-based methods generally involve one of three general types of tungsten oxide precursors: colloidal sols, alkoxide derivatives, and peroxy tungstic acid.

The gas sensing characteristics of Fe-doped (10%) tungsten oxide thin films of various thicknesses (100–500nm) prepared by electron beam evaporation. The performance of these films in sensing four gases (H2, NH3, NO2 and N2O) in the concentration range 2–10,000ppm at operating temperatures of 150–280°C has been investigated. The results are compared with the sensing performance of a pure WO3 film of thickness 300nm produced by the same method. Doping of the tungsten oxide film with 10at.% Fe significantly increases the base conductance of the pure film but decreases the gas sensing response. The maximum response measured in this experiment, represented by the relative change in resistance when exposed to a gas, was ΔR/R=375. This was the response amplitude measured in the presence of 5ppm NO2 at an operating temperature of 250°C using a 400 nm thick WO3:Fe film. This value is slightly lower than the corresponding result obtained using the pure WO3 film (ΔR/R=450). However it was noted that the WO3:Fe sensor is highly selective to NO2, exhibiting a much higher response to NO2 compared to the other gases. The high performance of the sensors to NO2 was attributed to the small grain size and high porosity of the films, which was obtained through e-beam evaporation and post-deposition heat treatment of the films at 300°C for 1h in air.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Analysis of Tungsten Oxide Nanowires Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 16:25

- Written by zsq

- Hits: 513

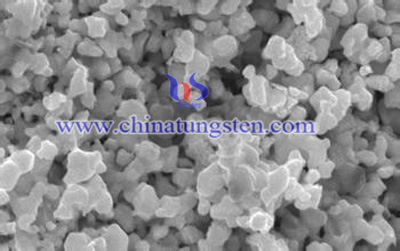

In the past few years, an increasing interest has been put on the tungsten oxide films due to their potential applications in smart windows, gas sensors, photocatalytic reactions, and optoelectronic devices etc. The unique properties of the tungsten oxide films were usually determined by the oxygen defects and the valence states of tungsten ions. Besides, it is very important to improve the properties of tungsten oxide films and other oxide films by controlling their morphologies and crystalline phases,which mainly depend on the preparation technologies and thermal treating temperatures and atmospheres.

When the temperature of the source and substrate changes, the growth of the tungsten oxide nanowires changes with regularity. i.e., as the temperature of the source of evaporation and substrate increases, the diameter of tungsten oxide nanowires increases gradually and its diameter increases faster than its height; as the temperature of the substrate increase, the height of the tungsten oxide also increases gradually and its height increases faster than its diameter.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Coated Tungsten Carbide Cutting Tools Mechanical Stress And Impact Damage

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 10:12

- Written by yewq

- Hits: 519

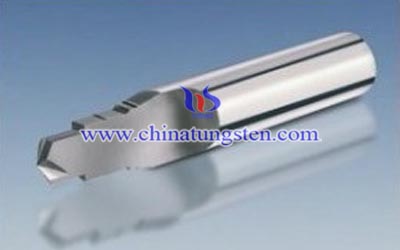

When cutting, the role of mechanical stress in the coating surface coated tungsten carbide cutting tools, coating and the substrate is first formed joints easily crack two sources to rapidly penetrate the surface coating matrix expansion, along with cutting progresses, shallow flaking will occur, this time the blade did not fail, as the cutting continues, the base material of the crack gradually extended in parallel in a network of cracks, peeling may occur deep, this time will result in a hard coating alloy tool failure. Residual stress state coated tungsten carbide cutting tools in initiation and propagation of cracks in the surface of the blade about the residual compressive stress can prevent crack propagation, which is resistant PVD coated tungsten carbide cutting tools coating flaking better performance reasons.

Impact damage is the main reason for the occurrence of coated tungsten carbide cutting tools when turning, when the impact load exceeds the allowable strength edge chipping occurs. Although low-temperature hardness of austenitic stainless steel, but it has serious work hardening, so the impact of a significant chipping occurs under load. Cutting edge radius smaller PVD coated tungsten carbide cutting tools, resulting in low impact resistance of the tool, could easily lead to impact damage PVD coated tungsten carbide cutting tools.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 16:21

- Written by zsq

- Hits: 519

Several methods are used to form tungsten oxide films. The methods include sputtering, chemical vapor deposition, and plasma enhanced chemical vapor deposition, in which sub-atmospheric pressure must be maintained. In these methods, large, complex and expensive equipment is needed, and the methods involve significant energy consumption and relatively high operating costs. The films produced by current methods are tungsten oxide films of WO3, without suboxides, and which are colorless or faint yellow, single color films.

It has been suggested that tungsten containing films be formed by a metallo-organic deposition (MOD) method, wherein an organic metal compound is applied to a substrate which is heated to form the desired metal oxide film. Most MOD processes for deposition of transition metal oxides use carboxylate salts. However, tungsten carboxylates have not been easily synthesized.

It is an object of this invention to provide an MOD method for producing a tungsten oxide film by pyrolyzing at least a portion of an alkyl amine tungstate compound; in which the alkyl amine tungstate compound is a soluble alkyl ammonium salt of tungstic acid; in which time and temperature of heating are varied so as to provide a desired color gradient in the tungsten oxide film and suboxides of the tungsten oxide (WO3); and which utilizes a precursor which produces a high tungsten oxide yield thereby forming a relatively dense tungsten oxide film.

It is a further object to provide tungsten oxide films which include suboxides of tungsten oxide (WO3); which have an average ratio of oxygen atoms to tungsten atoms equal to or less than 3:1; which are denser than films produced from currently known MOD precursor compounds; which have a color gradient, that is, a single continuous film marked by regions of different colors; and wherein the regions of color are electrochromic.

In this method, tungsten oxide films are formed without vacuum equipment. Uniform faint yellow to white (colorless) films having essentially no organic matter or impurities are produced, or films having regions of color across the substrate are produced ranging from nearly colorless or faint yellow to deep brown, which offer the potential for inexpensively and controllably darkening windows.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Wear Section

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 10:09

- Written by yewq

- Hits: 569

Tungsten carbide cutting tool wear process can be divided into early wear, normal wear and rapid wear in three stages:

1. Wear the early stages

The existence of the new coating flank rough place, residual stresses and micro-cracks and other defects after tungsten carbide cutting tools, and relatively sharp cutting edge, flank a smaller area in contact with the process, the pressure stress, therefore, at this stage wear faster wear rate of less the two tools.

2. Normal wear stage

With the increase in cutting time, the new tool after run-in, the contact area between the tool and the workpiece increases, the pressure decreases, and wear changes stabilized.

3. Rapid wear stage

In rapid wear stage, surface roughness thicker, cutting force and cutting tools are rapidly increasing temperature, tool wear faster. Sharp knives entered the stage of significant signs of wear stainless steel chip color changes from normal wear stage became dark yellow blue purple.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com