Electrochromic Tungsten Oxide Film Deposition

- Details

- Category: Tungsten Information

- Published on Tuesday, 10 March 2015 18:04

- Written by zsq

- Hits: 576

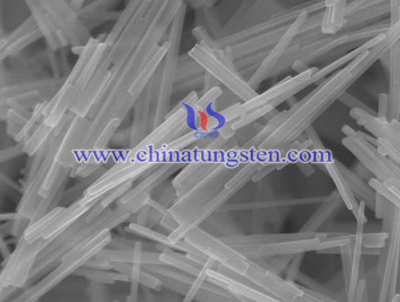

Tungsten trioxide (WO3) has been studied for many years. It is one of the best materials for use in the fabrication of electrochromic (EC) devices, such as electrically tintable glass for use in buildings and automobiles. WO3 has the desirable characteristics of transparency, chemical stability—as in the stoichiometry doesn't change with time after deposition—and relatively low cost. Typically, WOx, where 3>x>2.75, is desired for the EC application for the following reasons: (1) in the x>3 region, the oxygen is rich such that the WOx film may not be bleachable after lithium atom insertion; and (2) in the region x<2.75, the film is no longer transparent.

The deposition of WO3 films is of considerably interest, not least because of their electrochromic properties. Physical vapor deposition (PVD) is one of the conventional methods used for depositing EC films. During the Physical Vapor Deposition (PVD) WOx deposition, the stoichiometry of the film (value of x) is controlled by the oxygen partial pressure. However, the value of x changes with the oxygen partial pressure too sharply such that it is very hard to control in the range of interest—see FIG. 1; in addition, the deposition rate is very low. See T. J. Vink, E. P. Boonekamp, R. G. F. A. Verbeek and Y. Tamminga, Lithium trapping at excess oxygen in sputter-deposited a-WO3 films, Journal of Applied Physics 85(3), pp. 1540-1544, 1 Feb. 1999. According to Vink et al.'s data, reproduced in FIG. 1, control of the oxygen partial pressure to achieve an O/W ratio (value of x) of around 2.85 is very difficult due to the rapid change of x with oxygen partial pressure—such a process would have a very narrow process window and consequently would likely be a process with poor yield.

The two factors—narrow process window and low deposition rate—make the prior art PVD WOx film deposition process unattractive for use in the EC industry. Clearly, there is a need for improved deposition methods which provide sufficient control of the x value to allow high yield deposition of EC WOx films with x in the desired range of 3>x>2.75. Furthermore, there is a need for a deposition method for these EC films which provides a high enough deposition rate to satisfy manufacturing throughput targets at relatively low cost.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com