Simulation And Analysis of GaN Wafer Bowing on Sapphire Substrate

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Friday, 28 February 2014 11:15

- Hits: 2698

Using MOCVD (metal-organic chemical vapor deposition) to analyze the growth of GaN-base photoelectric  devices on the sapphire substrate is a common method in the semiconductor lighting industry. In recent years, along with the unceasing enhancement of epitaxy technology and related technologies, larger sapphire substrates are needed. The optimization and improvement of MOCVD reaction chamber structure with large-scale epitaxial wafers have been studied by many domestic researchers. Li et al. optimized high-frequency heating graphite base groove structure with eight-inch and twelve-inch substrates. Ying-lu et al.studied the heating modulate curve of radiation heating MOCVD and proposed the design principles of the outer heater. To improve the production efficiency, some great MOCVD manufacturers also focus on how to improve and increase the MOCVD cavity and the sapphire substrate size in foreign countries. At present, two-inch and four-inch epitaxial wafers are frequently used, so manufacturers who can produce six-inch SiC and Si substrate epitaxial wafers with high quality in foreign countries would sell chips abroad.

devices on the sapphire substrate is a common method in the semiconductor lighting industry. In recent years, along with the unceasing enhancement of epitaxy technology and related technologies, larger sapphire substrates are needed. The optimization and improvement of MOCVD reaction chamber structure with large-scale epitaxial wafers have been studied by many domestic researchers. Li et al. optimized high-frequency heating graphite base groove structure with eight-inch and twelve-inch substrates. Ying-lu et al.studied the heating modulate curve of radiation heating MOCVD and proposed the design principles of the outer heater. To improve the production efficiency, some great MOCVD manufacturers also focus on how to improve and increase the MOCVD cavity and the sapphire substrate size in foreign countries. At present, two-inch and four-inch epitaxial wafers are frequently used, so manufacturers who can produce six-inch SiC and Si substrate epitaxial wafers with high quality in foreign countries would sell chips abroad.

With the growth of the III-nitrides, sapphire becomes the most extensively used substrate material. Crystals of sapphire with good quality and low price can be easily got. Besides, sapphire is stable at high temperature and the growth technology of nitrides on sapphire is now fairly mature. However, the problem of wafer bowing, which results from the difference in thermal expansion coefficient between GaN epitaxial layer and sapphire, has become much more serious in larger-diameter wafers. It will deteriorate the contact between the substrates and the equipment stages or the subsectors during device process, which will result in degradation in the device uniformity or failures in lithography.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Morphology of the Surface of modified AlN/Sapphire Substrates Obtained by Thermochemical Nitridation Method

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Thursday, 27 February 2014 11:25

- Hits: 2546

Sapphire is the material most widely used in the capacity of substrates for technical devices based on the  nitrides GaN, InN, AlN and their solid solutions. However, the method of heteroepitaxy of the nitrides on sapphire substrates results in high dislocation density and other structure defects, due to discrepancy in the crystal lattice parameters and thermal expansion coefficients of these materials. This essentially complicates the obtaining of heterostructures with high functional characteristics. Since the commercial production of the substrates for homoepitaxial growth is expensive, much attention is being paid nowadays to the use of modified sapphire substrates with buffer nitride layers (GaN/sapphire or AlN/sapphire templates) which play the role of inherent nitride quasi-substrates. We have developed a new method for the obtaining of AlN/sapphire templates based on nitridation of sapphire in a gaseous mixture containing N2, СО, СО2, Н2, Н2О with low concentration of СО2 and Н2О.

nitrides GaN, InN, AlN and their solid solutions. However, the method of heteroepitaxy of the nitrides on sapphire substrates results in high dislocation density and other structure defects, due to discrepancy in the crystal lattice parameters and thermal expansion coefficients of these materials. This essentially complicates the obtaining of heterostructures with high functional characteristics. Since the commercial production of the substrates for homoepitaxial growth is expensive, much attention is being paid nowadays to the use of modified sapphire substrates with buffer nitride layers (GaN/sapphire or AlN/sapphire templates) which play the role of inherent nitride quasi-substrates. We have developed a new method for the obtaining of AlN/sapphire templates based on nitridation of sapphire in a gaseous mixture containing N2, СО, СО2, Н2, Н2О with low concentration of СО2 and Н2О.

This method allows to obtain polar AlN//Al2O3, AlN//Al2O3), semipolar (AlN// Al2O3) and nonpolar ( AlN// Al2O3) crystalline AlN layers on the surface of sapphire. Their thickness ranges between 20-30nm and several microns, the rocking curve half-width is less than 1º. In contrast to well-known deposition methods in which epitaxial films are obtained using external source, in the given method AlN layer is formed due to dissolution of nitrogen in anion-deficient corundum followed by crystal-chemical transformations in the surface-adjacent layer of sapphire substrate. Therefore, the nitride layer is to be formed after the stage of corundum reduction followed by etching of the substrate surface. The goal of the present work was to establish regularities of the influence of reducing annealing of sapphire substrate on the morphology of the surface of AlN/sapphire templates.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Effects of Sapphire Substrates Processes to The LED Efficiency

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 26 February 2014 14:18

- Hits: 2571

Recently, GaN-based blue and near-UV LEDs are extensively studied in the emerging solid-state lighting  industry as a key technology. The light extraction efficiency (LEE) is very important factor in fabricating high brightness, high efficiency GaN-based light-emitting diode (LED). As well known, the large difference in the refractive index between the GaN(2.40) and air caused a narrow escape cone for the light in GaN crystal. One most used method is roughness or texture on interfaces, such as the patterned sapphire substrate (PSS) recently and the increasing efficiency of PSS LED is considered as a consequence of the light scattering by the PSS. Huang, etc developed the side wall shaping and truncated inverted pyramid (TIP) shaping technology to increase the external quantum efficiency (EQE) of GaN LED.

industry as a key technology. The light extraction efficiency (LEE) is very important factor in fabricating high brightness, high efficiency GaN-based light-emitting diode (LED). As well known, the large difference in the refractive index between the GaN(2.40) and air caused a narrow escape cone for the light in GaN crystal. One most used method is roughness or texture on interfaces, such as the patterned sapphire substrate (PSS) recently and the increasing efficiency of PSS LED is considered as a consequence of the light scattering by the PSS. Huang, etc developed the side wall shaping and truncated inverted pyramid (TIP) shaping technology to increase the external quantum efficiency (EQE) of GaN LED.

The flip-chip technology is also wildly studied because of its excellent performance in thermal conductivity and EQE these years. But the influence of sapphire substrate processes in the back-end process is few considered. In this work, the relation between extraction efficiency of GaN-based LED and several parameters of the sapphire substrate is studied, including thickness, roughness and package method. Firstly, the thickness of sapphire substrate in the back-end processes is studied. After choose a better sapphire thickness, we develop the roughness method using just a grinding process and the bottom face periodic pattern by dry etching technique to improve the external quantum efficiency. The different surface structure on the bottom surface of sapphire substrates are analyzed basis on geometry ray tracing simulation, and compared with experiments.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

2013 Deep Research Report on Global And Chinese Sapphire Substrate Industry

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Thursday, 27 February 2014 11:11

- Hits: 2504

This 2013 Deep Research Report is a professional and in-depth research report on the Global and Chinese  sapphire substrate industry. The report begins by discussing the industry giving details on definition, classification, manufacturing process and product specifications.

sapphire substrate industry. The report begins by discussing the industry giving details on definition, classification, manufacturing process and product specifications.

The report then examines 17 Global and 12 Chinese manufacturers presenting information on capacity, production cost, selling price, profit, production value, profit margin, products, customers, raw materials and equipment sources.

The report also gives statistics on market shares, production market shares, global and Chinese demand, supply and shortage. It also offers details on price, cost, profit, production values and profit margins. Finally, the report also analyses the 3 million pieces sapphire substrate project feasibility analysis and related research conclusions.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

A Sapphire Substrate Sapphire Semiconductor Products

- Details

- Category: Tungsten & Sapphire Growth Furnace News

- Published on Wednesday, 26 February 2014 14:03

- Hits: 2562

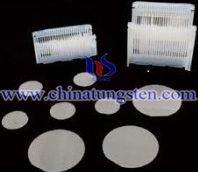

Sapphire semiconductor substrates are manufactured at sapphire products from high quality optical grade  Czochralski sapphire, integrated facilities allow regulation of the production of substrates from crystal growth to fabrication and to accommodate special requests on very short notice.

Czochralski sapphire, integrated facilities allow regulation of the production of substrates from crystal growth to fabrication and to accommodate special requests on very short notice.

Sapphire semiconductor substrates are available in all orientations including R-axis (10-12), C-axis (0001), A-axis (11-20), and M-axis (11-10). Substrates are available in various shapes (circular, rectangle, or square), from a few mm up to 100mm in size, and finishes according to customer specification. Primary flats(as per industry standards) are provided on circular substrates for orientation purposes; secondary flats are available on request. Substrate thickness' range from 0.013" (0.25mm) to 0.025" (0.675mm), depending on your particular application requirements.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com