Coreshell Technologies’ Nano-Coating Extends Life for Lithium Batteries

- Details

- Category: Tungsten's News

- Published on Friday, 28 August 2020 20:43

Coreshell Technologies, a California battery start-up company, raised US$4 million to develop a new nano-coating that can be used to extend the life of lithium batteries. The company founded in 2017 is currently working to improve what’s described as “electrode surface instability” on the electrode surfaces in a lithium-ion battery, which is directly responsible for the loss of energy during cycling. In addition to causing a loss in performance, battery degradation ultimately leads to higher costs.

The typical lithium-ion batteries that power electric cars are quite durable. However, they still tend to degrade over time, which eventually reduces their ability to retain a charge, as well as a reduction in the battery's energy density and service life. For battery manufacturers, reducing battery degradation will improve the overall performance of lithium-ion batteries, which are found in many of the world's electronic devices, including electric vehicles and energy storage systems. Coreshell Technologies is working to solve this problem and continue its research to improve lithium-ion batteries.

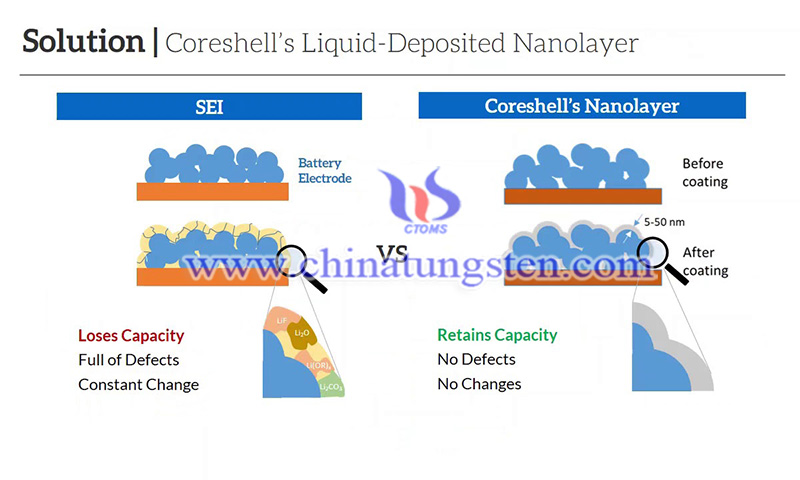

According to Coreshell Technologies, the special nano-coating developed by the company can be attached to the electrodes of the battery to reduce the impression of battery capacity decline caused by chemical reactions. It is reported that this technology can effectively increase the voltage range of the battery and increase the energy density of the battery.

From the perspective of principle, the formation of solid electrolyte interphase (SEI) is a process. The decomposition of the electrolyte will form a microscopic coating on the electrode surface inside the battery, and the decomposition of the electrolyte is produced by the charge and discharge cycles.

This process occurs when lithium ions and electrons move between positively and negatively charged positive and negative materials, and the nano-coating developed by Coreshell Technologies will block some of the electrons, resulting in faster SEI formation, while still allowing lithium ions move faster between the anode and cathode materials.

Coreshell Technologies said its first nano-coating product can reduce the cost of existing batteries by up to 30%, but the challenge is how to apply them to the production process of standard lithium batteries. It is worth noting that in addition to Coreshell, other companies are also dedicating on developing key materials that can extend battery life.

A joint research team led by Professor Nam-Soon Choi and Professor Sang Kyu Kwak in South Korea has developed an ion-concentrated electrolyte using a solvent containing fluorine atoms for lithium batteries, which can simultaneously protect the battery electrodes and increase output. The improved electrolyte system is expected to solve the problem of the reduction and oxidative decomposition of unstable ether-based electrolytes in high energy density lithium metal batteries with high nickel cathodes.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com