Cesium Tungsten Oxide Ultra Fine Powder Preparing Method

- Details

- Category: Tungsten Patents

- Published on Monday, 22 February 2016 17:22

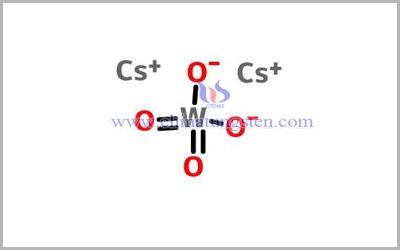

Tungsten oxide has excellent performance in electrochromic, catalysis, gas and other aspects. The composite oxides - tungsten bronze metal oxides generally refer darker colored metallic luster, and usually a metal conductor or metal semiconductor. Currently, cesium tungsten oxide, due to its low resistance and excellent visible light transmittance and near-infrared shielding properties, is widely used in the preparation of the conductive film used in glass septum thermal insulation coating.

The traditional preparation method of cesium tungsten oxide uses tungsten, tungsten acid source, Cs/W molar ratio of 1: (2.857~100), at 180~200°C reaction conditions for 1~3 days. The preparation takes a long reaction period, is of low efficiency, which is not conducive to industrial production.

A process for preparing cesium tungsten oxide ultrafine powder, comprising the steps of:

(1) In accordance with Cs / W molar ratio of 1: (1.5 to 2.8), weigh cesium salt and tungsten salt. A chelating agent and alcohol reagent are added and reacting under 170 °C condition for 3h. Then mix them up.

(2) The step (1) was charged into a pressure vessel bomb reaction under 260 ~ 270°C reaction condition for 5 ~ 8h;

(3) The Step (2) was obtained by reaction of an alcohol wash, centrifugation, at 80°C under conditions of complete crystallinity dried in vacuum to obtain cesium tungsten oxide powder.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com