Epoxides Catalyzed by Phosphomolybdophosphate Tungstophosphoric Acid

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 November 2019 23:54

Heteropolyacids have been developed for more than 100 years, and the research contents have been gradually extended to material chemistry, electrochemistry, catalytic chemistry, photochemistry, surface science, medicine and other fields. Therefore, heteropolyacids show high catalytic activity and selectivity for various organic reactions.

Epoxy compounds are important intermediates for organic synthesis and chemical materials. The ternary ring of epoxy compounds has special tension, so it is easy to synthesize many kinds of substances needed by people through selective ring opening or functional group conversion. This process can be catalyzed by phosphomolybdophosphate tungstophosphoric acid with low cost, high yield, no pollution to the environment, recyclable catalyst and recycling catalyst. The process is as follows:

1)The brominated ionic liquid was obtained by heating and refluxing the brominated alkane, N-methylimidazole or pyridine or quaternary ammonium salt for 8-48h, adding the solvent and rotating evaporation after the reaction;

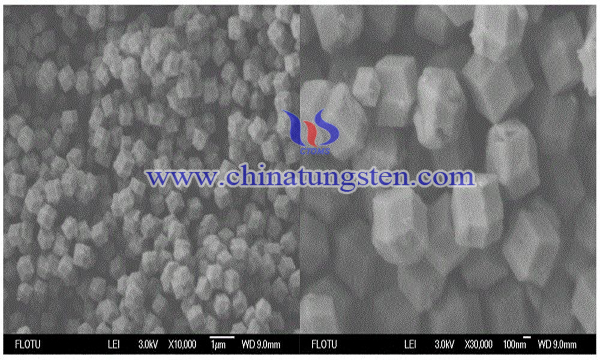

2)Dissolve the brominated ionic liquid in hydrochloric acid to obtain solution a; dissolve the heteropoly acid precursor h3pmo3w9o40 in hydrochloric acid to obtain solution B; mix solution a and solution B, stir at room temperature for 1-5h, filter after the reaction, wash with water several times, and finally dry in the drying box to obtain the powder product, namely phosphomolybdophosphate tungsten heteropoly acid.

3)Ddd the ionic liquid, catalyst phosphomolybdophosphoric acid, oxidant and substrate olefin into the reaction vessel in turn, stir them, heat them in a water bath at 30-90 ℃, reflux reaction for 30-80mim, stop the reaction, reduce the temperature to 50 ℃, and fully shake and extract the reaction liquid.

In the traditional olefin epoxidation process, a large number of organic solvents such as dichloromethane are used, which are directly discharged to the nature and pollute the environment. Using Molybdophosphoric tungstophosphoric heteropoly acid as catalyst and ionic liquid EMIM [reo4] as solvent, the process is simple, the reaction is green and pollution-free, and the catalyst can be recycled, which greatly reduces the cost of catalyst while ensuring the catalytic effect.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com