Tantalum Doped Six Square Tungsten Oxide Nanomaterials

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 August 2019 21:29

90 Sr is an important heat-releasing nuclide in fragment solution. Separation of 90 Sr from fragment acidic solution can greatly reduce the cost of subsequent treatment of radioactive waste liquor. However, the separation of 90 Sr from fragment acidic solution is a very challenging task.

Hexagonal tungsten oxide (hex-WO3) is a kind of inorganic porous material with octahedral coordination unit structure. Crystalline microporous hexagonal tungsten oxide has a very high ion exchange capacity for 90Sr in nitric acid solution. HTB loaded with 90Sr can be directly converted into ceramic solidified by sintering. Therefore, the introduction of variable valence transition metal ions into the microporous skeleton structure is one of the effective means to obtain efficient separation materials.

A tantalum-doped nano-tungsten oxide adsorbent has been developed, which is characterized by introducing transition metal tantalum into WO6 octahedral structure and replacing part of W6+ with Ta5+ to make the octahedral structure have larger specific surface area, more negative charges and more favorable Sr2+ ion exchange. The preparation method of tantalum-doped hexagonal tungsten oxide nanomaterials includes the following steps:

(1)7-10 portions of sodium tungstate, 8.5-9 portions, were weighed and placed in polytetrafluoroethylene reactor, 7-10 portions of secondary distilled water were added, and 8.5-9 portions were selected as the optimum, and stirred to dissolve them fully.

(2)Ta/W molar ratio is 0.01-0.18 and the optimum is 0.05-0.12 by adding tantalum pentachloride ethanol solution with different concentration of 0.05 mol/L in the above solution. Continue stirring and mix well.

(3)7-10 hydrochloric acid solutions with concentration of 2-3 mol/L were selected as 8.5-9, 7-10 ammonium sulfate solutions with concentration of 0.4-0.5 mol/L were selected as 8.5-9, and stirred for 0.5-1 h in the polytetrafluoroethylene reactor.

(4)Seal the PTFE reactor and place it in the program oven. The heating and cooling rates are controlled to 1-2 ℃/min, respectively. The reactor is taken out and cooled to room temperature by hydrothermal treatment at 170-200 ℃ and preferably 170-180 ℃ for 24-48 H. The reaction products are washed to neutral with distilled water and then cooled at - 40 ℃. Ta-doped hexagonal tungsten oxide nanomaterials were obtained by freeze-drying for 24-48 hours in a freeze-drying machine.

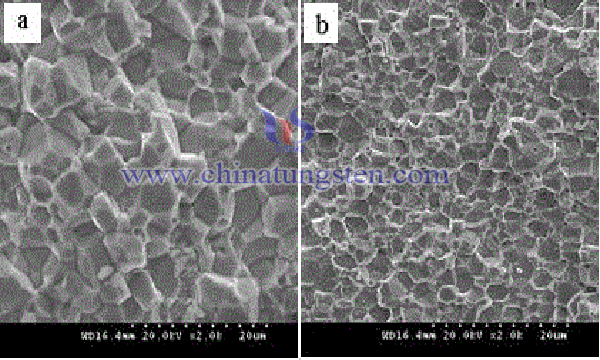

The phase of hex-WO3 samples obtained by Y-4Q X-ray diffractometer (XRD) with different tantalum doping amounts was analyzed, and the XRD and standard spectra of the products were obtained. The products were hexagonal tungsten oxide with strong diffraction peaks on 001 plane, which was the growth direction of the crystals. With the increase of tantalum doping amount, the crystallinity of the products decreased, and the main derivative was obtained. The shift of emission peak to low angle increases the interlayer spacing of 001 crystal plane, which is beneficial to ion exchange.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com