Tungsten Carbide Gear Hob Introduction

- Details

- Category: Tungsten Information

- Published on Monday, 27 October 2014 18:45

- Hits: 320

Tungsten Gold Plated Bar Story -- Aliens hunting for gold on Earth? 1

- Details

- Category: Tungsten Information

- Published on Monday, 27 October 2014 13:46

- Hits: 326

The Earth has become the battleground for extra-terrestrials to further their own political agenda for the future of the planet, a researcher has claimed. In South Africa’s first UFO science and consciousness conference held recently in Johannesburg, the organiser said that the royal political bloodline was a small group of families whose origins could be traced to the first of mankind and who were inevitably in contact with the aliens.

“There’s a battle for Earth by some interesting dark forces,” News24 quoted Michael Tellinger, the organiser as saying.

“All the governments in the world are puppets and instruments to implement the will of a small group of individuals. The royal political bloodline goes back thousand of years,” he said.

According to Tellinger, the South African government was one of the most important puppets of these extra-terrestrials because the country was rich in gold and diamonds.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Brazed Cutting Tools

- Details

- Category: Tungsten Information

- Published on Friday, 24 October 2014 17:55

- Hits: 366

How to Drill With a Tungsten Carbide Drill Bit

- Details

- Category: Tungsten Information

- Published on Friday, 24 October 2014 17:26

- Hits: 312

Tungsten Carbide Bits Vs. High Speed Steel Bits

- Details

- Category: Tungsten Information

- Published on Friday, 24 October 2014 16:49

- Hits: 294

Tungsten Carbide Cylindrical Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Friday, 24 October 2014 16:43

- Hits: 308

Tungsten Carbide Plain Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Friday, 24 October 2014 16:42

- Hits: 290

Tungsten Carbide Rough Surface Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Friday, 24 October 2014 16:40

- Hits: 296

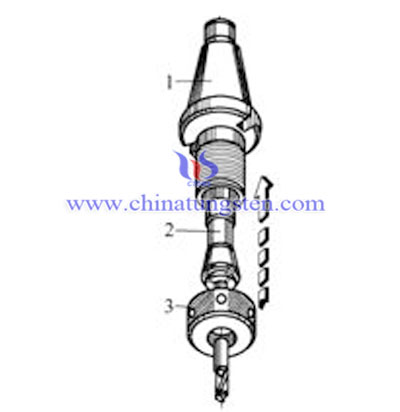

Tungsten Carbide End Mill Clamping

- Details

- Category: Tungsten Information

- Published on Friday, 24 October 2014 16:39

- Hits: 301

Tungsten Carbide Ball End mill Introduction

- Details

- Category: Tungsten Information

- Published on Friday, 24 October 2014 16:37

- Hits: 293

sales@chinatungsten.com

sales@chinatungsten.com