Tungsten Carbide Boring Cutter Installation

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 November 2014 18:45

- Hits: 285

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Reins Tungsten Nail Sinkers

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 November 2014 08:56

- Hits: 296

When it comes to weighting a lure, there is no other choice but reins tungsten nail sinkers to get the job done! In doing so, you can easily get the bait down to the "perfect" level where it has a chance to be consumed in one gulp! With its popular barbs, reins tungsten nail sinkers are sure to stay firmly in place throughout the cast.

Reins tungsten nail sinkers help you fine tune your baits, they are used on soft plastics or on wood plugs. Commonly, rein tungsten nail sinkers can be used in the nose of a worm to give you just the right action, or maybe you need to balance that frog or plus to swim just right.

Why Tungsten

Tungsten, with the density rages from 16.5 to 18.5, is widely used by more and more manufacturer in making reins nail sinkers. Reins tungsten nail sinkers have better penetration power compared with other materials made nail sinkers, such as lead, brass, est. Besides, reins tungsten nail sinkers are environment friendly, which is an important factor nowadays.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Angle End Mill Introduction

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 18:23

- Hits: 303

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Die Milling Cutter Introduction

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 18:19

- Hits: 302

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool CVD Coating Technology Development

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 18:17

- Hits: 292

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

High-Density Heavy Metals for Radiation Shield

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 14:02

- Hits: 284

Tel.: 86 592 5129696; Fax: 86 592 5129797Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Alloy for Efficient Radiation Protection

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 13:59

- Hits: 279

Tel.: 86 592 5129696; Fax: 86 592 5129797 Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Nail Sinkers

- Details

- Category: Tungsten Information

- Published on Monday, 03 November 2014 13:41

- Hits: 328

Nowadays, a popular approach to weighting down soft plastics is the advent of small tungsten nail sinkers to add small amounts of weight internally to soft plastic lures.

Tungsten nail sinkers are thin and nail-like weights insert into soft-plastic baits, like jerk baits, sticks or finesse worms. Tungsten nail sinkers can be used to balance rigged jerk bait for a natural-looking fall. Another option is tail-weighting finesse worms for a tail-first, fall that can trigger hits from shy, following fish.

Tungsten nail sinkers are perfect for adding a small amount of weight to your soft plastic lures. An adjustment in weight can make the difference when conditions on the water change or you want to modify your bait's action. Easily clipped down with standard line clippers, tungsten nail sinkers are an ace-up-your-sleeve. The ability to make quick changes helps you stay one step ahead.

Each active tungsten nail sinker comes with three factors: a sharp tip to penetrate any section of the soft plastic lure, a narrow shank profile to minimize damage to the soft plastic lure and a set of conical barbs along the length of the shank to securely fasten the tungsten nail sinkers into the body of your soft plastic lure.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Manufacturers Should Keep an Eye on Tungsten Carbide Cutting Tool Wear

- Details

- Category: Tungsten Information

- Published on Friday, 31 October 2014 18:54

- Hits: 364

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

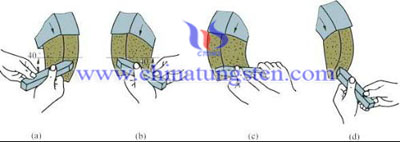

Tungsten Carbide Turning Tool Sharpening

- Details

- Category: Tungsten Information

- Published on Friday, 31 October 2014 18:49

- Hits: 312

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com