Cesium Tungsten Bronze Nanopowder Applied for Glass Curtain Wall Thermal Insulating Coating

- Details

- Category: Smart Glass

- Published on Thursday, 14 November 2019 17:54

- Written by Yahong

- Hits: 1493

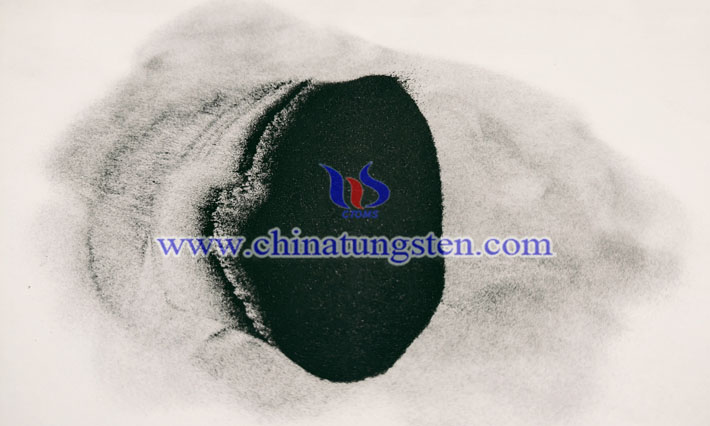

Cesium tungsten bronze nanopowder for producing glass curtain wall thermal insulating coating can be prepared by a stirred bead milling process using high-performance batch-type stirred bead mill.

More details, please visit:

http://cesium-tungsten-bronze.com/index.html

The experts added the Cs0.33WO3 coarse powder (10 wt.%) to the aqueous solution of potassium hydroxide at pH 8, and then they put the dispersion into the stirred bead mill. An agitation speed of 2,400 rpm (peripheral speed 10 m/s) was set to exert both shearing and imparting forces on the Cs0.33WO3 coarse powder and was run for different times. Samples were taken at various intervals of grinding time for particle size analysis. The filling ratio of the mill chambers by grinding beads was 60 vol.%. The mill was operated at a constant temperature of 20°C.

The high-performance batch-type stirred bead mill consists of a rotor, a mill chamber, and grinding beads. The rotor and mill chamber are made of highly wear-resistant materials: sintered silicon carbide. The mill chamber is cooled with water and has a net grinding charmer volume of 350 mL. The grinding beads are fluidized by the rotor in the mill chamber as the grinding medium.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com