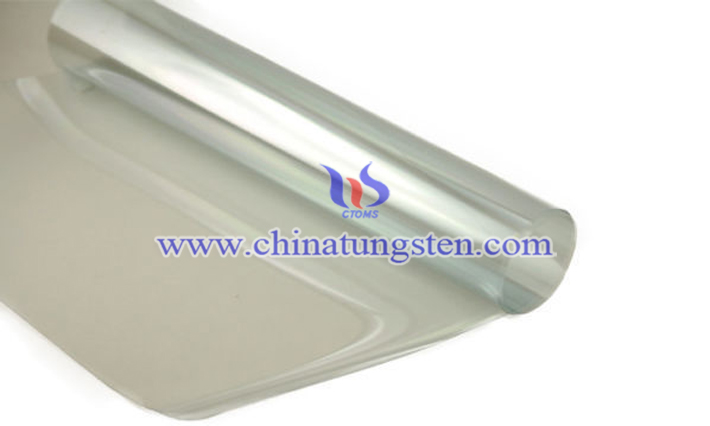

Ti-doping WO3 Electrochromic Film

- Details

- Category: Smart Glass

- Published on Thursday, 18 April 2019 17:40

- Written by Yahong

- Hits: 1627

The experts used metal tungsten and tungsten-titanium alloy targets to prepare Ti-doping WO3 electrochromic film by pulsed DC reactive magnetron sputtering method.

More details, please visit:

http://www.tungsten-powder.com/tungsten-oxide.html

Experts used X-ray diffraction, Raman spectroscopy, scanning electron microscopy, atomic force microscopy, X-ray photoelectron spectroscopy, electrochemical workstations and other analytical testing methods to study the effects of the crystal structure, surface topography and electrochromic properties such as modulation amplitude, response time, color change efficiency and cycle life on the film thickness, substrate temperature, oxygen partial pressure and other coating process parameters. They also compared the structure, surface morphology and properties of the tungsten trioxide electrochromic film before and after Ti doping, and explained the influence mechanism of Ti doping on the electrochromism of tungsten oxide. Experts found that the lattice strain and surface roughness of WO3 film changed before and after coloring. As the thickness of the film increased, the change value first decreased and then increased. When the thickness was 250nm, the change value was the smallest. At this time, the tungsten trioxide had higher optical modulation amplitude and color change efficiency. Therefore, 250nm is the optimum thickness of the tungsten trioxide film as the electrochromic functional layer.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com