Tungsten Trioxide Photocatalyst Disarming Intruder from Inside

- Details

- Category: Tungsten's News

- Published on Thursday, 02 June 2016 18:29

- Hits: 652

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Button Developments

- Details

- Category: Tungsten's News

- Published on Thursday, 02 June 2016 16:37

- Hits: 543

Recent years, due to mechanization and intelligent technology developments, tungsten carbide products used for drilling has a rapid development. The main trends include the following: ultra-fine or nano structure tungsten carbide, high-temperature powder based tungsten carbide, functionally gradient carbide, carbide modified binder, double bonded carbide and WC-Co-diamond three phase composite hard materials and so on.

1. Ultra-fine or nano structure tungsten carbide button: It is one of the hotspot recently. In the early 1990s, related researchers began to focus on grain refining preparing submicron ultrafine and nano-structured carbide launched a study. This is owing to with the continuous grain refinement, the density, the hardness, the toughness and the wear resistance of tungsten carbide materials will be remarkably improved. At the same time drilling equipment for drilling requirements are also getting higher and higher, especially high-pressure drilling of wear resistance and toughness carbide button have strict requirements, and ultrafine grain cemented carbide can fully meet its performance.

2. High-temperature powder based tungsten carbide button: It is one kinds of new process that high-temperature reducing raw material powder and high temperature carbonization, which the preparation of WC powder has integrity, high strength and high energy storage. Compared with conventional vacuum heat treatment, average footage carbide button ratio increased by 50%, drilling speed of nearly 100%, with an average increase of about 100% abrasion resistance, product quality and stability and service life have been greatly improved.

3. Functionally Gradient carbide buttons: In sintering or heat treatment process through the appropriate climate-induced diffusion in the alloy C, and through a chemical reaction so that other members rearrangement and distribution, leading to changes in alloy composition and structure along a certain direction, forming a gradient structure, different parts with different functions. Functionally Gradient carbide buttons usually low carbon alloy carburizing process (pass into CH4, CO and other carbon-containing gas) method of extraction, the treated W and Co ball distribution in the diameter direction. This structure gives button higher wear resistance and toughness, both functionally graded cemented carbide DTH drill, drill or cone ball tooth drill bit life have a significantly improved.

4. New binder modifying carbide buttons: Treatment with molten metal (Ni or Si as alloying additive elements), Ni and Si alloy can significantly improve the ability of anti-fatigue cracks. In addition, Ni sintered alloy melt to permeate the process of WC skeleton occurred off junction formed developed WC / Co sintered alloy phase interface, the grain size is reduced, thereby the fracture toughness increases. The results show that the solder alloy cone rotary drilling bit, the working efficiency is improved by 1.8 times.

5. Double bonded carbide: Compared with conventional tungsten carbide, tungsten carbide pellet is composed of sintered pellets instead of hard compound. The sintered pellets mixed with a binder metal and a second sintering, thereby making the fracture toughness without lowering the hardness of the premise of a substantial increase.

6. WC-Co-diamond three-phase composite hard materials: High temperature high pressure synthesis, powder / polymer mixture extruded into green compacts, and then consolidated by high temperature and pressure synthesis of diamond. It has many advantages, such as reducing the mismatch in thermal expansion and elastic stress off the diamond enhanced; diamond enhanced surface and the wear resistance improved; Fracture toughness of WC-Co- diamond composite surface is excellent, improve service life.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Micro-drill Rods Has Been Overcome

- Details

- Category: Tungsten's News

- Published on Thursday, 02 June 2016 16:35

- Hits: 483

With the rapid development of science and technology, whether mechanical industry or microelectronics and even medical fields, all tends to miniaturized and sophisticated. Even the traditional carbide industry is no exception, conventional carbide bar diameter range is generally φ1-40mm. Tungsten carbide rods is also known as tungsten carbide bars, which consists of refractory metal compound as a hard phase and a binder phase metal. Due to its high hardness, high density, high strength and excellent wear and corrosion resistance, it can be widely used in metal cutting tools, drills, grinding tools. But tungsten carbide material is brittle, so there is a great difficulty on tungsten carbide ultra-fine rods manufacturing, which is always a barrier in the development of domestic tungsten carbide industry,

Recent years, some domestic enterprises had a breakthrough in tungsten carbide ultra-fine tungsten carbide rods. In general, in conventional tungsten carbide industry, fabricating diameter of less than 3mm rod is already a certain degree of difficulty. But they through continuous efforts to break through technical difficulties, it is now capable of producing ultra-fine 0.6mm tungsten carbide rods. Throughout the development process, from ingredients, pressing to sintering, each procedure they have to conquer one by one. It requires the use of ingredients when nano-scale particles as a main raw material, and meanwhile pay attention to the ratio of raw materials; the most difficult part is pressing and drying section, due to the mold mouth is very small, conventional extrusion molding agent is hard to achieve extrusion molding. So the relevant researchers updated the recipe of the agent by searching the materials abroad and find the best solution; sintering process is also a part needs precise controlling, due to the small diameter once a parameter error will shrink products uneven, resulting in deformation. Through continuous testing, and finally developed an alternative to imported products for ultra-fine micro-drilling diameter tungsten carbide rods, to break the foreign monopoly on the Chinese market. Currently, tungsten carbide ultra-fine rods mainly used in PCB (Printed Circuit Board) drilling, and the micro-drill by high-speed steel used in dental has been replaced by tungsten carbide micro-drills gradually.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Heater - Customs Announcement No. 11, 2016

- Details

- Category: Tungsten's News

- Published on Thursday, 02 June 2016 11:07

- Hits: 505

Since Jeong eun kim was in office, earthshaking changes have taken place for the domestic matters in North Korea, gradually he takes the full control of the political situation. He becomes the real master of all states' rights, and it seems to have a tendency to centralization of power. Recently, North Korea is in a time of emergency whose political situation is relatively unstable, therefore, the China made clear regulation for transporting minerals for North Korea. In the April 5, 2016, the Ministry of Commerce of the People's Republic of China published an embargo for partial minerals for North Korea.

Since Jeong eun kim was in office, earthshaking changes have taken place for the domestic matters in North Korea, gradually he takes the full control of the political situation. He becomes the real master of all states' rights, and it seems to have a tendency to centralization of power. Recently, North Korea is in a time of emergency whose political situation is relatively unstable, therefore, the China made clear regulation for transporting minerals for North Korea. In the April 5, 2016, the Ministry of Commerce of the People's Republic of China published an embargo for partial minerals for North Korea.

Announcement mainly mentioned that import coal and iron and iron ore from North Korean is prohibited. Unless the imports have been proven that they were not produce in North Korean and importers should provide information and application to provincial competent commercial section, after a series of proof then importers can import things. Secondly, it is not allowed to import gold ore, vanadium and titanium ore and rare minerals. There is also a ban on the export of aviation fuel, including aviation gasoline, naphtha type jet fuel, kerosene type jet fuel and kerosene rocket fuel to North Korean, unless it has passed through the UN Security Council Sanctions Committee.

With the rapid development of chinese economy, wolfram heater industry also continues to expand and grow, and since China has been joining the WTO, the export of this industry is gradually increased. Although the past two years, the export situation in China is not optimistic, but in accordance with relevant policy information issued by the State which did not make strict controls for tungsten heater, indicating that wolfram heater still has good investment prospects. What’s more, with the continuous improvement of the national scientific and technological strength, quality and quantity of tungsten heater has been improve, coupled with the reputation "Tungsten City", therefore, tungsten heat would remain the stable development of the state.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Overseas Companies Successfully Separated Rare Earth Element Scandium

- Details

- Category: Tungsten's News

- Published on Wednesday, 01 June 2016 18:33

- Hits: 479

| Rare Earth Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Haze Governing Advantageous Weapon - Tungsten Trioxide Desulfurization Catalyst

- Details

- Category: Tungsten's News

- Published on Wednesday, 01 June 2016 17:40

- Hits: 565

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Li Chen Initiated "Running Blue", Tungsten Trioxide Denitration Catalyst to Cheer

- Details

- Category: Tungsten's News

- Published on Wednesday, 01 June 2016 17:37

- Hits: 650

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Plasma Component Technology Breakthrough

- Details

- Category: Tungsten's News

- Published on Wednesday, 01 June 2016 14:53

- Hits: 638

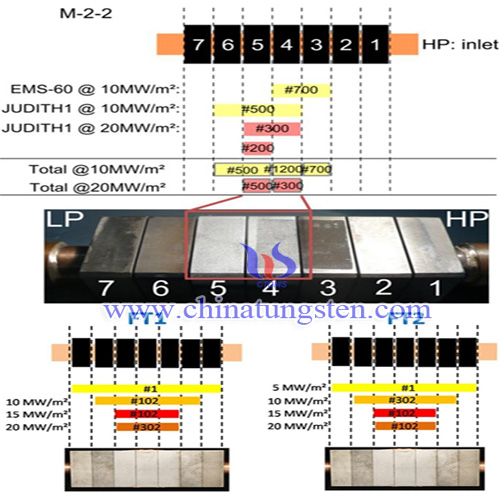

Recently, French Atomic Energy Commission (CEA) / Institute of magnetic confinement fusion (IRFM) researchers announced a good news: Institute of Plasma Physics, Chinese Academy of Sciences has made key progress in the development of two types of tungsten copper heat load (HHF) test module towards plasma components (W / Cu-PFC) test. Tungsten copper towards plasma component mainly refers to perforated tube. Tungsten copper perforated tube is one of the parts of vertical divertor target plates, and the divertor has been playing an significant role in magnetic confinement fusion reactor.

The main role of divertor is that the interaction between plasma and materials processing separated in two chambers and separates the resulting doping source and the main plasma. In general, it uses High heat load irradiation for the divertor properties testing, which is an important criteria to evaluate the quality of tungsten copper perforated tube. Tungsten copper not only has high melting point, high strength, low coefficient of thermal expansion, low sputter rate, low retention and excellent wear and corrosion resistance, etc., which is recognized as the most suitable for future nuclear fusion reactor plasma-facing materials. Tungsten copper perforated tube is first to drill on tungsten block, followed by brazing or hot isostatic pressing (HIP) block and other technology tungsten chromium zirconium copper pipe connected. Since it has symmetry in structure, can relief the thermal stress concentration and eliminate the stress point so that it can withstand high thermal loads irradiation.

Tungsten copper perforated tube fabricated by HIP has well combining face and without any obvious cracks, but the wall thickness of the circumferential unevenness in the HIP process of collapse and cracking phenomenon occurs. This time, the Chinese Academy of Sciences has made a major breakthrough in the manufacture of technology in the international community for the first time to achieve mass production of tungsten copper PFC, tungsten plasma interaction to carry out a comprehensive study under the conditions of long-pulse high parameters and provides an excellent platform. According to IREM researchers report relevant results: W / Cu perforated tube (Mono-block) No. 4 block modules withstand 1,200 times 10MW / m2 and 300 20MW / m2 radiation heat load; No. 5 tungsten block withstood 500 10MW / m2 and 500 20MW / m2 radiation heat load beyond the International Thermonuclear Experimental Reactor ITER to 20MW / m2 radiation heat load 300 requirements. In addition, W / Cu plates (Flat type) module FT1 to withstand 102 times 10MW / m2,102 times 15MW / m2 and 302 times 20MW / m2 radiation heat load; Tablet Module FT2 withstood 302 times 10MW / m2,102 times 15MW / m2 and 102 times 20MW / m2 radiation heat load. Irradiation results far beyond the flat module 5 MW / m2 in the ITER design requirements, refresh the W / Cu plate member is known recording HHF tests. This also proves that the advanced nature of the plasma connecting tungsten copper PFC technology to some extent.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

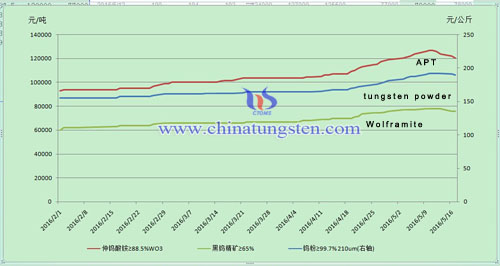

Chinese Mines Reduce Production, Tungsten and Antimony Prices Rise

- Details

- Category: Tungsten's News

- Published on Friday, 27 May 2016 16:47

- Hits: 794

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Market Short-Term Shocks

- Details

- Category: Tungsten's News

- Published on Thursday, 26 May 2016 18:31

- Hits: 1076

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com