Liu Yuanjun and Xie Wenge Grabbed 2016 PDC World Cup Qualifying Tickets

- Details

- Category: Tungsten's News

- Published on Friday, 29 April 2016 17:39

- Hits: 703

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Oxide Photocatalytic Degradation of Dye Pollutants

- Details

- Category: Tungsten's News

- Published on Thursday, 28 April 2016 15:10

- Hits: 913

A WO3–graphene photocatalyst has been developed that can degrade the dye Rhodamine B almost completely in 15 minutes. This is much faster than the degradation times that can be achieved by bare WO3 or TiO2. The catalyst consists of a porous WO3 framework with a graphene film and is directly produced via electrospinning. The authors from China and the USA envision that this potent electrocatalyst can be used in environmental applications for the degradation of pollutants under visible light.

The superior properties of the photocatalyst can be explained by its components and structure. The WO3 nanoframework efficiently absorbs visible light due to multiple reflections in the pores. A rapid charge transfer to graphene takes place, which avoids charge recombination. Additionally, graphene nanosheets are exposed on the surface. This enables π–π conjugation between graphene and dyes leading to high adsorption rates of the substrate on the catalyst material. These combined properties lead to enhanced dye degradation via photocatalysis.

Scientists proposed that WO3–graphene composite can be used to address challenges in environmental remediation. In this context, they highlight that the facile preparation of the material via electrospinning is suitable for production on an industrial scale.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Origin of Chinese HGV WU-14 Warhead

- Details

- Category: Tungsten's News

- Published on Wednesday, 27 April 2016 18:29

- Hits: 1331

It was said that foreign media reported WU-14, a new Chinese hypersonic weapon speculated, had been tested 10 times the speed of sound super weapon by Chinese military on Jan. 9, 2014, whose purpose is to break the U.S. missile defense system.

Application of Tungsten Compounds to an Inhibitor against Bacterial Damage of Concrete

- Details

- Category: Tungsten's News

- Published on Tuesday, 26 April 2016 18:27

- Hits: 2221

Atsunori NEGISHI, Terunobu MAEDA

Hazama Corporation.

Technical Research Institute.

Abstract

China's Largest Sapphire Crystal Produced Promotes Tungsten Thermal Field Development

- Details

- Category: Tungsten's News

- Published on Tuesday, 26 April 2016 18:16

- Hits: 585

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Oxide-- New Material of Concrete Antimicrobial and Anticorrosive in Sewer

- Details

- Category: Tungsten's News

- Published on Monday, 25 April 2016 17:36

- Hits: 726

Sewer is the integral part of infrastructure in a city which plays an irreplaceable role in the living environment of safety, construction and comfortable. In recent years, the corrosion degradation has caused many social problems, such as the collapse of the road, and thus attracted widespread attention.

Sewer is the integral part of infrastructure in a city which plays an irreplaceable role in the living environment of safety, construction and comfortable. In recent years, the corrosion degradation has caused many social problems, such as the collapse of the road, and thus attracted widespread attention.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Darts—Assisting for 2016 PDC Chinese Tryout

- Details

- Category: Tungsten's News

- Published on Thursday, 21 April 2016 17:15

- Hits: 764

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

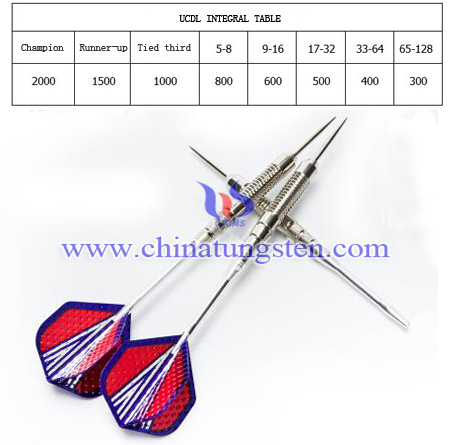

The CUDL is Starting Soon with Popular Tungsten Darts

- Details

- Category: Tungsten's News

- Published on Friday, 15 April 2016 17:13

- Hits: 583

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

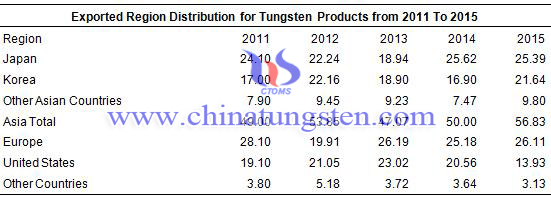

China Tungsten Industrial Competitiveness Evaluated Based on Tungsten Products Export

- Details

- Category: Tungsten's News

- Published on Monday, 11 April 2016 18:25

- Hits: 604

Tungsten is a valuable scarce resource, which takes about 0.001% in the earth crust. It is referred as “Tooth of Industry” because of its properties of high melting point, density, hardness. Tungsten and its products are widely used in modern industry, which is an important non-renewable mineral resource, its development closely link with national economic lifelines and security. To some extent, the situation of tungsten export over the years reflected the changes of China tungsten industry competitiveness in the international market; in 2015, China canceled the export quota and turned to the export license management system, which means tungsten manufacturers will have to rely on technology in order to survive, companies should focus on the optimization of high, refined, sharp and deep processing.

Tungsten is a valuable scarce resource, which takes about 0.001% in the earth crust. It is referred as “Tooth of Industry” because of its properties of high melting point, density, hardness. Tungsten and its products are widely used in modern industry, which is an important non-renewable mineral resource, its development closely link with national economic lifelines and security. To some extent, the situation of tungsten export over the years reflected the changes of China tungsten industry competitiveness in the international market; in 2015, China canceled the export quota and turned to the export license management system, which means tungsten manufacturers will have to rely on technology in order to survive, companies should focus on the optimization of high, refined, sharp and deep processing.| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

2015 China Tungsten Products Import and Export Market Analysis

- Details

- Category: Tungsten's News

- Published on Monday, 11 April 2016 18:21

- Hits: 576

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com