Forging Process of Producing Tungsten Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 14:57

- Written by wenjing

- Hits: 356

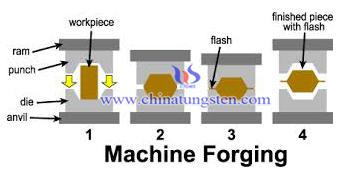

Forging is a main machining process to produce tungsten radiation shielding.Tungsten and several tungsten alloys have been successfully forged over a wide range of temperatures from as low as 1800 to 3500F. In rocket nozzle forging, a billet height reduction of approximately 80% at forging temperatures below the critical recrystallization temperature is considered essential. This imparts the fine-grained, fully wrought, fibrous structure that is characteristic of high strength and good ductility at low transition temperatures.

Tungsten is generally forged in the hot-cold work temperature range where hardness and strength increase with increasing reductions. Both systems exhibit increase forgeability with decreasing grain size. The greatest use of tungsten forgings has been in rocket nozzle applications. Production forging of tungsten nozzle inserts has been largely limited to billets prepared by powder metallurgy techniques because of their earlier availability than cast tungsten.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Polymers for Medical Devices

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 14:55

- Written by wenjing

- Hits: 317

Tungsten polymers are used to produce catheters and other devices that are inserted into the body for diagnostic or interventional procedures are commonly filled with substances opaque to x-rays, thereby rendering the devices visible under fluoroscopy or x-ray imaging. These fillers, or radiopacifiers—tungsten(typically dense metal powders)—affect the energy attenuation of photons in an x-ray beam as it passes through matter, reducing the intensity of the photons by absorbing or deflecting them. Because these materials exhibit a higher attenuation coefficient than soft tissue or bone, they appear lighter on a fluoroscope or x-ray film. This visibility provides the contrast needed to accurately position the device in the affected area. Image contrast and sharpness can be varied by the type and amount of radiopacifier used, and can be tailored to the specific application of the device.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Extrusion Process of Tungsten Alloy Shielding

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 August 2015 18:53

- Written by wenjing

- Hits: 324

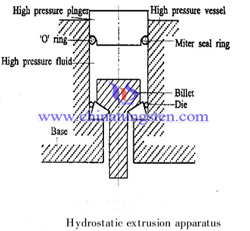

Extrusion, which is a process used to create objects of a fixed cross-sectional profile. Tungsten alloy material can be pushed or pulled through a die of the desired cross-section in extrusion process. The extrusion process may also increase the strength of tungsten alloy shielding.

The process begins by heating the stock material (for hot or warm extrusion). It is then loaded into the container under the press. A dummy block is placed behind it where the ram then presses on the material to push it out of the die. Afterward the extrusion is stretched in order to straighten it. If better properties are required then it may be heat treated. The extrusion ratio is defined as the starting cross-sectional area divided by the cross-sectional area of the final extrusion. Compared with forging, one of the main advantages of the extrusion process is that this ratio can be very large while still producing with quality. For the extrusion process, only one compression can cause extrusion ratio is about 60%~80%. In forging process, one compression cause extrusion ratio is no more than 20% ,otherwise the scrap rate will be greatly enhanced.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Radiation Shielding Materials Applications

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 August 2015 18:56

- Written by wenjing

- Hits: 286

A particularly dense material with excellent shielding properties is needed to ensure that the surrounding tissue is protected and the radiation guided only to the intended locations--high density tungsten alloys are widely used as medical and industrial radiation shielding applications.

Tungsten alloys are used for radioactive source containers, gamma ray protection, radiation shields, x-ray shielding and source holders for oil-well, logging, and industrial instrumentation. We can also use our tungsten alloys to make collimators and shielding for cancer therapy machines, and as syringe protection for radioactive injections.

There is no licensing required for tungsten alloy materials. Tungsten alloys are stable at high temperatures. You can use one-third less material than lead for the same energy-absorbing effectiveness, meanwhile it is non-toxic.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Something about Ammonium Paratungstate Structure from Lanthanum Tungsten Electrode Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 August 2015 18:19

- Written by Yahong

- Hits: 346

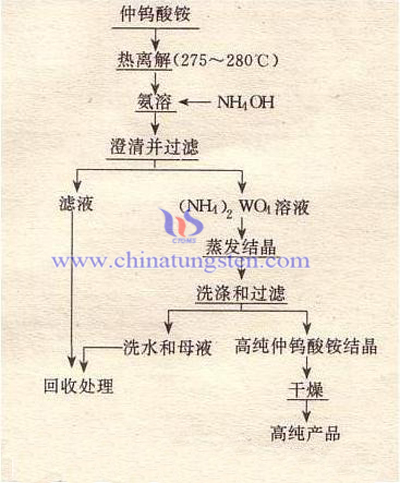

Ammonium paratungstate (APT) is one of the materials for the preparation of lanthanum tungsten electrode, which is a kind of white crystalline salt. After World War II, there are literatures showing that the anion in (NH4)10(W12O41) ·5H2O has been proved to be [H2W12O42]10−, holding two hydrogen atoms inside the cage. Tungsten-oxygen cage, the focus of the anion, requires 42 oxygen molecules. Therefore, the correct formula expression for ammonium paratungstate is (NH4)10[H2W12O42] ·4H2O. On the contrary to the paratungstate A ion, whose anion is [W7O24]6−, the paratungstate B ion is [H2W12O42]10− ion, which is similar to the paramolybdate ion. However, the existence of the paratungstate A ion can’t be confirmed by NMR (Nuclear Magnetic Resonance) spectroscopy.

Before 1930, there had been some argument about the exact composition of the salt, and someone had proposed the two structures at that time: (NH4)10W12O41 and (NH4)6W7O24. And O.W. Gibbs had said that” the alkali tungstate are unusually complex. Salts of essentially different formula is so close in composition ratio that the differences lie very near the unavoidable errors of analysis. The analysis is hardly sufficiently close to deciding the question on purely analytical grounds."

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com