Tungsten Carbide Porous Nozzle Factors II

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:39

- Written by xiaobin

- Hits: 308

In the beginning, tungsten carbide porous nozzle uses the impact of water-flow for rock cracking. After that it depends on the returned flow for scouring the wall and associate with jet-flow pressure, which deepens the hole and increases the volume. Some related experimental statistics show that the growth of aperture will decrease with as time goes by and every type of nozzles are similar, which explains that tungsten carbide porous nozzle aperture is determined by the diameter of hole D and less influenced by quantity of holes. In addition, with the increasing numbers of spraying holes, the roundness of hole will increase. And less holes will make flow disperse and can not connect well, which make it out of round.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Porous Nozzle Factors I

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:36

- Written by xiaobin

- Hits: 326

First of all, the time of erosion has an influence on the efficiency of tungsten carbide porous nozzle for drilling. Generally, if erosion time is longer, the aperture, hole depth and the broken volume will increase. However, the raising trends will be different due to various types of nozzles. As tungsten carbide porous nozzle, with time goes by, the hole depth and broken volume will increasing remarkably at the beginning and tend to gently. It is proves that the principle of water-flow for rock cracking is a dynamic process and has obvious periodicity.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

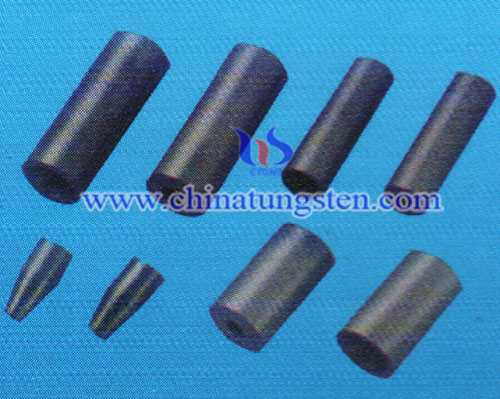

Tungsten Carbide Sand-blasting Nozzle II

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:30

- Written by xiaobin

- Hits: 299

It not only enhances the hardiness of film, but also improves mechanical and anti-fatigue performance. Regardless of inhale-type dry sand blaster, press-in dry sand blaster or fluid sand blaster, tungsten carbide nozzle is an essential part of them. The sand-blasting processing is widely used in surface derusting, which caused by electrochemical corrosion and leaves many pits on that.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Sand-blasting Nozzle III

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:32

- Written by xiaobin

- Hits: 293

There are two common difficulties when tungsten carbide sand-blasting is working. One is the difficult suction, the other one is about abrasion. The main reason is the size of the sand entry is too small and the vacuum is not enough. While the inside blowhole do not match the straight section mixed with sand and water or the material of straight section mixed with sand and water is inappropriate so that the nozzle is badly abrasive.

Therefore, the quality of tungsten carbide sand-blasting nozzle is determined by inhaling tube diameter, the size of blowhole, the straight sections and the materials. Controlling the distance of nozzle and steel plate is the most importance to achieve the best result. In addition, adding corrosion inhibitor will prevent the metal surface from two-stage oxidation.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Sand-blasting Nozzle I

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:28

- Written by xiaobin

- Hits: 300

The Sand-blasting processing uses the impact energy of high-speed sand flow and compressed air to coarsening and cleaning the surface of matrix. It consists of copper mine sand, emery and quartz sand, etc. Through impacting and cutting on the surface of work pieces by grinding compound, the surface and the shape of metal work pieces will be changed for getting roughness and cleanliness.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com