Injection Molding Screw

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 October 2017 23:28

Plasticizing quality and yield of injection molding products are mainly affected by two aspects: first, the influence of injection molding process conditions; and two, the influence of screw structural parameters.

The screw is the core component of the injection molding machine. Its function is to transport, compact, melt, stir and press the plastic.

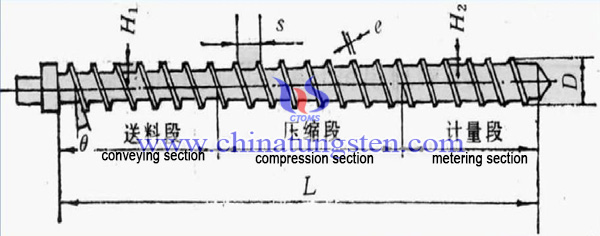

So, the structural design of the injection screw has a very important impact on the plasticizing quality of the product. Injection molding screw in general circumstances can be divided into conveying section (also known as feeding section), compression section and metering section (also known as homogenizing section). As shown in the following figure.

(1) Conveying Section

Groove depth in this section is fixed. And its function is responsible for preheating, conveying and pushing of materials. Theoretically, the deeper the groove depth is, the greater the throughput is. But in the actual design, the strength of the screw and pressure loss problems also should be considered.

(2) Compression Section

The function of the compression section is material melting, mixing, shearing, compressing and pressurizing exhaust. Tungsten material is almost completely dissolved in this section, and the volume of the material will shrink.

For materials passing through this section, the design of the compression ratio is very important. The screw compression ratio is the ratio between the depth of the last groove at the conveying section and the depth of the first groove in the measuring section, reflecting the compression degree of the material through the compression section.

When the length of the compression section is constant, the greater the compression ratio, the more severe the material compression, finally the more shear heat will be generated. On the contrary, the smaller. Therefore, the compression section is the part that determines the shear heat of the material. The low shear screw compression ratio is generally 1.8-2.2.

(3) Metering Section

The metering section is the groove depth of the screw groove. Its main function is mixing evenly, melting adhesive transport and metering. And it must provide sufficient pressure to ensure that the uniform temperature of melt adhesive and stability of the flow of molten plastic. A long metering section is easy to stay plastic for too long, leading to thermal decomposition. When the section is section is too short, the material temperature will be uneven.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com