Tungsten Powder Applied in Manufacturing Bullet and Cartridge Case

- Details

- Category: Tungsten Information

- Published on Thursday, 30 June 2016 17:58

It is well known in the industry to manufacture bullets and corresponding cartridge cases from either brass or steel. Typically, industry design calls for materials that are strong enough to withstand extreme operating pressures and which can be formed into a cartridge case to hold the bullet, while simultaneously resist rupturing during the firing process.

Conventional ammunition typically includes four basic components, that is, the bullet, the cartridge case holding the bullet therein, a propellant used to push the bullet down the barrel at predetermined velocities, and a primer, which provides the spark needed to ignite the powder which sets the bullet in motion down the barrel.

The cartridge case is typically formed from brass and is configured to hold the bullet therein to create a predetermined resistance, which is known in the industry as bullet pull. The cartridge case is also designed to contain the propellant media as well as the primer.

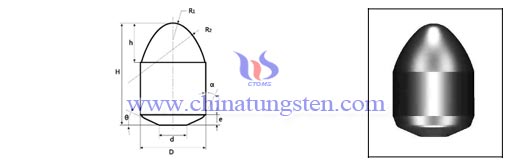

The bullet is configured to fit within an open end or mouth of the cartridge case and conventionally includes a groove (hereinafter referred to as a cannelure) formed in the mid section of the bullet to accept a crimping action imparted to the metallic cartridge case therein. When the crimped portion of the cartridge case holds the bullet by locking into the cannelure, a bullet pull value is provided representing a predetermined tension at which the cartridge case holds the bullet. The bullet pull value, in effect, assists imparting a regulated pressure and velocity to the bullet when the bullet leaves the cartridge case and travels down the barrel of a gun.

Furthermore, the bullet is typically manufactured from a soft material, such as, for example only, lead, wherein the bullet accepts the mouth of the cartridge being crimped to any portion of the bullet to hold the bullet in place in the cartridge case, even though the cartridge case is crimped to the cannelure of the bullet.

The propellant is typically a solid chemical compound in powder form commonly referred to as smokeless powder. Propellants are selected such that when confined within the cartridge case, the propellant burns at a known and predictably rapid rate to produce the desired expanding gases. As discussed above, the expanding gases of the propellant provide the energy force which launches the bullet from the grasp of the cartridge case and propels the bullet down the barrel of the gun at a known and relatively high velocity.

The primer is the smallest of the four basic components used to form conventional ammunition. As discussed above, primers provide the spark needed to ignite the powder which sets the bullet in motion down the barrel. The primer includes a relatively small metal cup which contains a priming mixture, foil paper, and relatively small metal post, commonly referred to as an anvil.

When a firing pin of a gun or firearm strikes a casing of the primer, the anvil is crushed to ignite the priming mixture contained in the metal cup of the primer. Typically, the primer mixture is an explosive lead styphnate blended with non-corrosive fuels and oxidizers which burns through a flash hole formed in the rear area of the cartridge case and ignites the propellant stored in the cartridge case. In addition to igniting the propellant, the primer produces an initial pressure to support the burning propellant and seals the rear of the cartridge case to prevent high-pressure gases from escaping rearward. It should be noted that it is well known in the industry to manufacture primers in several different sizes and from different mixtures, each of which affects ignition differently.

The cartridge case, which is typically metallic, acts as a payload delivery vessel and can have several body shapes and head configurations, depending on the caliber of the ammunition. Despite the different body shapes and head configurations, all cartridge cases have a feature used to guide the cartridge case, with a bullet held therein, into the chamber of the gun or firearm.

The primary objective of the cartridge case is to hold the bullet, primer, and propellant therein until the gun is fired. Upon firing of the gun, the cartridge case seals the chamber to prevent the hot gases from escaping the chamber in a rearward direction and harming the shooter. The empty cartridge case is extracted manually or with the assistance of gas or recoil from the chamber once the gun is fired.

The polymer material preferably has a specific gravity of 3–10, more preferably 6–9, and most preferably 7.5–8.5. Preferably, the polymer material has a specific gravity which permits the molded bullet to provide a user with a point of aim that is comparable to that of the conventional lead products. A bullet formed in accordance with the present invention is environmentally friendly as it does not have any lead, performs ballistically similar to conventional bullets, has a lower weight while using the same firearm hold characteristics, and can be produced at a substantially lower manufacturing cost. Furthermore, the composite polymer material preferably encapsulates the tungsten powder such that the composite polymer bullet does not wear down the barrel of the firearm, which results in a longer life for the firearm.

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com