Copper Plating on Tungsten Carbide Cutting Tools (1/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 16:18

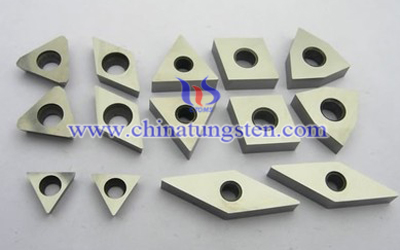

Theoretically, deposit a diamond layer on tungsten carbide cutting tools by using CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition), which can be remarkably improve the properties of tungsten carbide. But the most common problem is the match of thermal performance and the binding force between cemented carbide substrate and the coating layer. So the researchers find that applying a layer of transition between the coated film and the cemented carbide substrate can significantly improve the performance of the film base. It refers to plating a metal layer on tungsten carbide cutting tools, which is the new attempt used electrodeposited layer as transition.

Cu has good wettability on diamond tools and in the CVD diamond deposition process, the Cu plating layer is almost not affected by the temperature, which is one of the ideal transition layer materials. The basic process of copper plating on tungsten carbide cutting tools: workpiece fabricating → pretreatment → washing → pre-plating → electroplating → washing. Since the most of the products are made of cemented carbide WC, TiC and other metal carbide and a binder composed of Co and prepared by powder metallurgy method, so there are some pores and defects between the grains, which means the corresponding pretreatment process for tungsten carbide coating layer is crucial. In order to remove the oxide layer on tungsten carbide surface, we usually choose pickling method. But this will lead to the shedding of small amount of Co on the surface and increase the pores on the surface. And the corresponding loss of Co binder role carbides will more easily expose to fall off so that the binding property of the coating is significantly reduced.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com