Tungsten Electrode Production Technology - Hydrogen Reduction

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 11:54

Rare earth tungsten electrode greatly improved pure tungsten electrode welding performance and greatly broadened in welding, plasma welding, cutting, painting and other areas application. The production techniques failed to break greatly constricts rare earth tungsten electrode industrialization production. Therefore, to study tungsten electrode production technology has a certain significant on tungsten electrodes volume production and application field expansion. The production processes of tungsten electrode include raw material doped-pressing-pre-sintered- sintered-swaging process-recrystallization annealing-drawing-straightening-polished and so on.

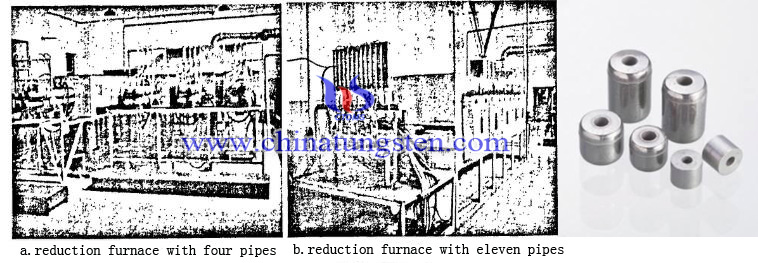

Using two-step hydrogen reduction method to obtain elemental metal tungsten and uniformly doped rare earth oxide powder, using hydrogen as reducing agent. The main reactions in reduction reaction are rare earth nitrate decomposition, APT decomposition and tungsten oxide reduction. China is the largest tungsten and related products producer, thus reducing furnaces in industrial production have high automation level and can automatic control a plurality of temperature zones’ temperature. During the reduction process, adjusting each temperature zone reduction temperature, generally obtained powder particle size are in line with production requirements. The first reduction general operated in reduction furnace with four pipes, and the second reduction operated in reduction furnace with eleven pipes. The whole reduction process is divided into five temperature zones and the third temperature zone is the highest.

Tungsten powder and rare earth oxide powder’s average particle size and bulk density is quality standard. Bulk density refers to per unit volume freedom filled tungsten powder’s weight, usually showing g/cm3, and it is a simple and fast way to evaluate thickness of the powder. The average particle size is another reference index for particle thickness testing.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com