Tungsten Electrode Production Technology - Doping Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 11:51

Tungsten electrode used in welding, cutting, painting and metallurgical industry is more and more widely. Pure tungsten electrode has higher electron work function, therefore it is difficult to arcing and arcing stability is also poor. Adding rare earth oxides can improve the pure tungsten electrode welding performance to improve the shortages of pure tungsten electrode, thus greatly expand the application areas of the electrodes. The common rare earth tungsten electrodes include thorium tungsten electrodes, cerium tungsten electrode and lanthanum tungsten electrode.

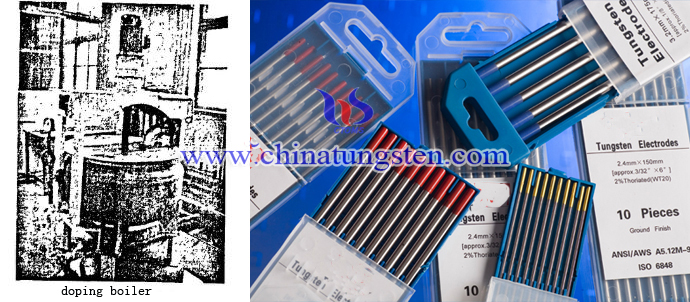

Tungsten electrode usually uses powder metallurgy method to produce. The main processes include doping, mixing, pressing, pre-sintered, sintered to produce blank, then through multistage swaging process recrystallization annealing, drawing straightening, polishing and a series of processes to get the finished products. Tungsten electrode production processes are complex, from the original powder doped to obtain the finished product to be subjected to more than a dozen steps, interlocking and interaction between each step. Therefore control tungsten electrode‘s production process, to develop a reasonable process parameters for obtain high-performance tungsten electrode has great significance.

Doping process is the first step of tungsten electrode production. Whether uniform doped rare earth or not will have direct impact on tungsten electrode performance. Earlier doping method is solid-solid method to doping with tungsten oxide doped and other rare earth oxides, but the effect is not ideal. After continuous improvement on doping method, at the present manufacturers usually use solid-liquid doping method. Solid-liquid doping mainly doped tungsten oxide with rare earth nitrate solution. This solid-liquid doping method greatly improves doping uniformity and improves tungsten electrode’s performance.

Putting a certain proportion of tungsten oxide and rare earth nitrates into the doping pot, when tungsten oxide was thoroughly wetted by the rare earth nitrate solution, to start doped pot impeller, heated with stirring to achieve uniform doping .

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com