Tungsten Copper Sintered Properties (1/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 16:08

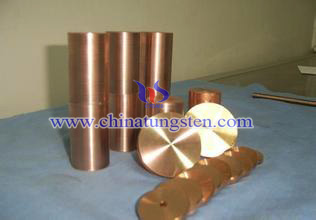

Tungsten copper composite sintered body directly affects the comprehensive performance of final product so that the determination of the relative aspects of density, hardness, conductivity, shrinkage, scanning electron microscopy and crushing strength becomes essential. Next, we will combine the experience of some relevant theoretical principles and production practices as summarized in one by one analysis of the test method.

Relative Density Test: It usually uses Archimedes drainage method, which weighs tungsten copper sintered in the air and in distilled water separately by electronic balance. Subsequently removed with a filter paper and then sintered body dry surface of the water and drying weighed. The conclusion that the actual density tungsten-copper sintered body, the relative density and opening rate formulas based on Archimedes' principle.

Hardness Test: Different from Rockwell hardness of tungsten carbide, tungsten copper products commonly tested by Vickers hardness. The basic process is to measure metallographic sandpaper good surface finish to standard mirror wafer sample was placed on a micro hardness tester, then a relative angle between the plane of a rectangular pyramidal diamond indenter of 136 °, using 0.1kgf (0.98N) pressure pressed into the sample surface. After a period of time (usually set 10S), remove the pressure with a magnification of 40 times optical microscope to accurately measure the length of indentation diagonal by formula Vickers hardness (HV = 0.1891 × F / d2, HV Vickers hardness, F is the applied pressure, d is the amount of indentation diagonal arithmetic mean) obtained the hardness.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com