Cleaning SCR Denitration Catalyst on Production Process

- Details

- Category: Tungsten Information

- Published on Friday, 19 February 2016 16:41

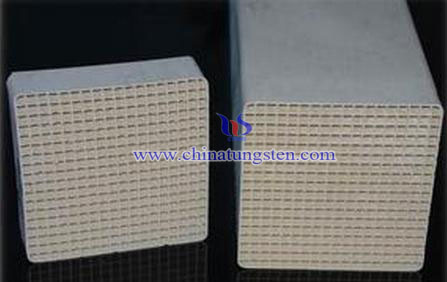

The activity of SCR denitration catalyst in-service will decrease by being abraded from flue gas, deposited from solid material, poisoned from alkali metal. And then after 2 or 3 years the catalyst would lose activity and end its life. Cleaning the SCR denitration catalyst is becoming very necessary because it costs high, and belongs to consumables. At the same time, the waste catalyst is difficult to handle because of the toxicity which will cause secondary pollution to the environment easily. We push a method for cleaning SCR denitration catalyst on the production process, steps as following:

1. Configure the cleaning solution

Stirring with a machine to mix oxalic acid solution, dispersing agent MF, ammonium metavanadate and ammonium paratungstate for more than 10 minutes for generating cleaning solution. Among them, the mass concentration that MF is 0.1-1wt%, ammonium metavanadate is l-3wt%, and ammonium paratungstate controlled at 5-15wt%. The pH value of the oxalic acid solution supposed to be 5-7;

2. Blowing and cleaning the surface of SCR denitration catalyst by a sonic soot-blower for 15s, and then cleaning the surface and pore of catalyst for 1min in certain circumstances;

3. Washing the SCR denitration catalyst for 5mins, and collect the waste liquid at the same time;

4. Washing the SCR denitration catalyst with cleaning solution for 10-20mins, also the waste liquid should be collected;

5. Dry the catalyst through a hot air drying device for 2-4 hours, thus finish the progress of cleaning SCR denitration catalysts.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com