Tungsten Carbide Ball Grinding Methods (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 19 February 2016 16:27

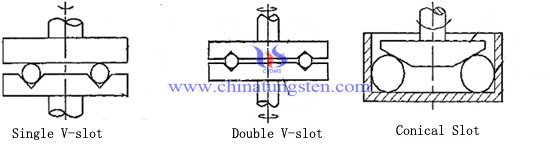

Tungsten carbide ball double V-slot grinding can ensure that the rotation angle of the ball will change with sphericity, but it requires that the grinding tray V-slot up and down has higher properalignment and shape error and assembly error institutions needed to be effectively controlled, otherwise the blank ball can not roll along the groove smoothly. The relevant domestic scholars have done a lot of this research and developed a conical grinding method in which the abrasive disk is tapered, which makes carbide ball blank has a large corner across from the milling process (usually up to 45 ° left and right), to obtain a full rotation, enhanced rotary slide ball blank, improving overall processing efficiency. The following is a schematic view of the three grinding work mode, you can clearly see different from the design of the grinding tray:

tungsten carbide ball grinding methods

Besides these three kinds of conventional grinding methods, Related researchers and academics abroad in order to achieve high-speed grinding ceramic balls have also proposed a flexible and high material removal rate of magnetic fluid polishing. Its basic principle is to use magnetic fluid mixing abrasive particles as an abrasive, when the magnetic fluid is given a certain magnetic field, the magnetic fluid will produce upward thrust, by the corresponding floating disc ceramic balls implement processing load. It remarkably improve the efficiency of precision ceramic ball and its roundness error less than 0.14μm, surface roughness reaches 0.01μm, material removal rate reaches 12μm / min, which is more than 40 times that of conventional grinding method.

However, this method due to the complex structure, inconvenient operation, and the magnetic fluid itself heightening price, after the magnetic fluid and particles worn when machining, material removal will be affected to some extent, it is also the emergence of a non-magnetic fluid polishing (water and glycerol mixture) instead of magnetic fluid and resin bonded diamond grinding wheel instead of embedding the abrasive grinding tray. Although the processing efficiency and processing efficiency and non-abrasive magnetic fluid magnetic fluid grinding pretty, its precision can not be fully guaranteed, both of structure of them are relatively complex, which is not suitable for large-volume production of high-precision machining of tungsten carbide ball.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com