Tungsten Copper Electrode—Explosive Powder Compaction (2/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 14 January 2016 17:20

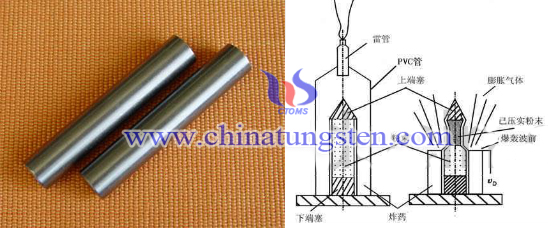

Actually, direct explosion pressing method does not require a large investment in equipments and it has simple structure of device. The following picture is one of the common device of direct explosion pressing method in the domestic researches:

The powder was placed there end plugs in low-carbon steel or aluminum (initial density of 50%), processed and evacuated sealed tube covered with a suitable amount of uniform thickness and density of the explosives. After detonator ignition occurs at a constant velocity along the wall down the tube and the detonation powder compaction, its detonation velocity and pressure depends on the role of the type of explosive. However, there are some defects blocks out the industrialization and standardized production of explosive powder compaction process. The biggest factor is the high speed loading generated by explosive compaction molding, it is difficult to obtain effective management and control, on the other hand, the explosion parameter dependencies and to be pressed powder types is still in the study.

After explosive compaction billet annealing for 2 hours at 900 ℃ in a vacuum oven, and the aging process. Then Vickers hardness (HV) hardness detection sample, using the Archimedes method (comparison, ideological integration method) after detecting sintering density of the sample preparation, and then by scanning electron microscopy (SEM) observation of fracture morphology products. We can observe the stress distribution of the fracture surface and breaking patterns. Overall, the explosive powder compaction is the use of explosive shock wave generated by loading technology compacted powder, powder high speed friction and heat insulation under the shock adiabatic shear action, suggesting that local high temperature, so that the surface layer melted particles the purpose of metallurgical bonding, and compacting the powder achieved by powder mainly plastic deformation and fragmentation.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com